Hidden lifting tea table

A hidden, coffee table technology, applied in the field of coffee table tables, can solve the problems of easy pinching of the user's fingers, great safety hazards, and inability of two flip covers to close together.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

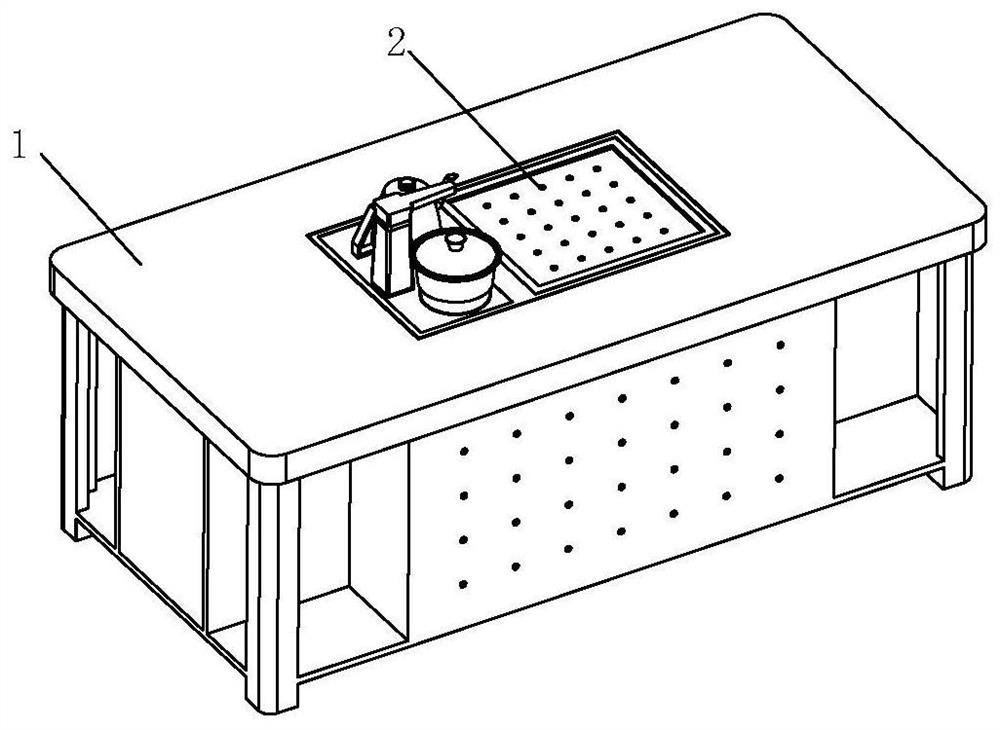

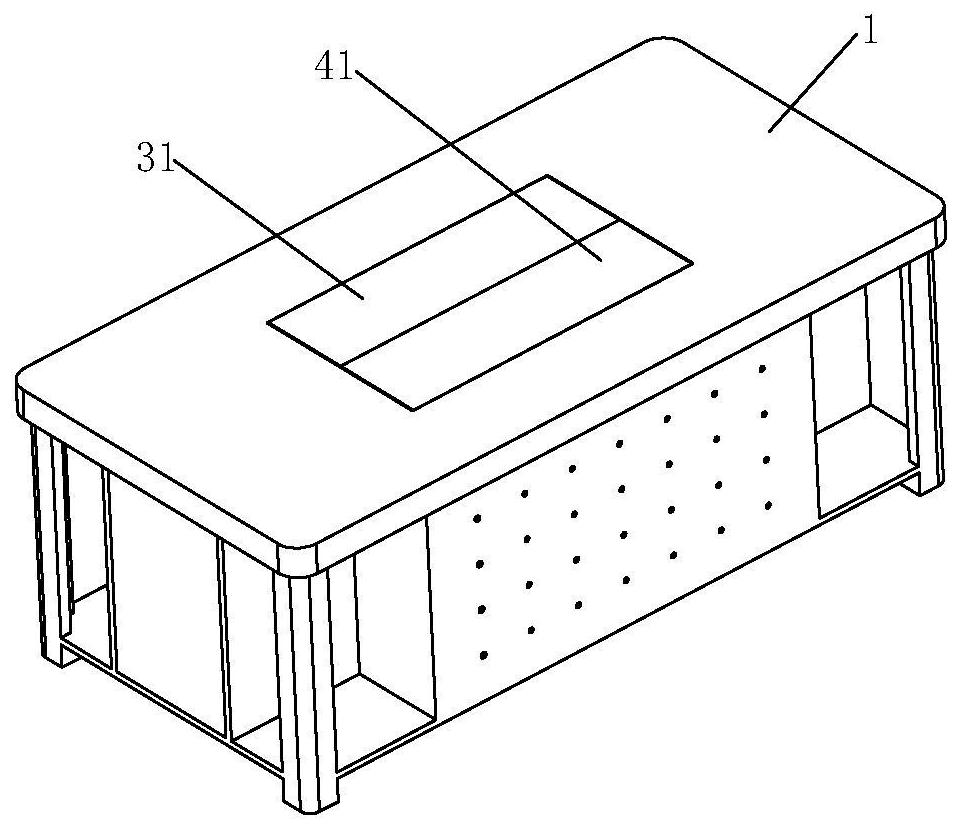

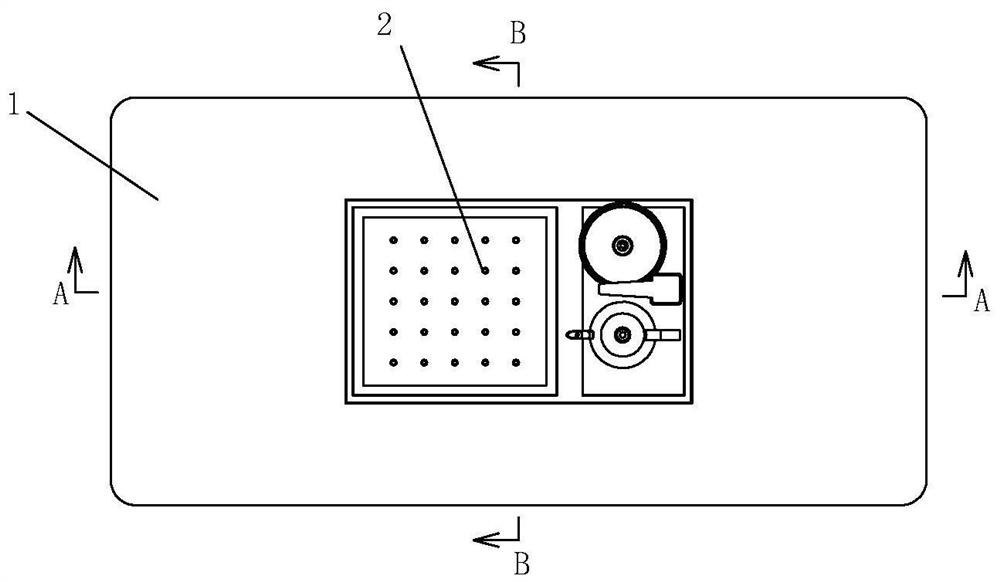

[0072] Embodiment one, such as Figure 1 to Figure 30 Shown, a hidden lift coffee table table, including table body 1, coffee table 2, first flip cover 41, second flip cover 31, fixed plate 19, two lifting motors 5, 51, first cover flip The linkage mechanism 13 and the second cover flipping linkage mechanism 14, the table body is provided with a coffee table storage cavity 11 for accommodating the coffee table, the desktop of the table body is provided with an opening 12 corresponding to the coffee table storage cavity 11, the The first cover plate turning linkage mechanism 13 and the second cover plate turning linkage mechanism 14 are arranged in the storage chamber 11 of the coffee table, and are located on the left and right sides of the coffee table 2. The first cover plate turning linkage mechanism 13 and the second cover plate turning linkage mechanism The two cover plate turning linkage mechanisms 14 all include a support frame 7, a lifting block 90, a lifting screw man...

Embodiment 2

[0089] Embodiment two, such as Figure 31 to Figure 32As shown, the second embodiment is similar to the first embodiment, the difference is that the improved hidden lifting coffee table in this embodiment has only one lifting motor, and the lifting motor is a dual output motor, and this embodiment improves the hidden lifting coffee table The table also includes a first gear box 65, a second gear box 64, a third gear box 63, a fourth gear box 62, a first transmission shaft 68, a second transmission shaft 69, a third transmission shaft 67, and a fourth transmission shaft 66. , the first lifting transmission bevel gear 616, the second lifting transmission bevel gear 613, the first transition bevel gear 615 and the second transition bevel gear 614, the first transmission shaft 68, the second transmission shaft 69, the third transmission shaft 67 and the second transmission shaft The four transmission shafts 66 are arranged in a shape, and the two output ends of the dual-output mot...

Embodiment 3

[0091] Embodiment three, such as Figure 33 to Figure 35 As shown, the third embodiment is similar to the implementation of the first embodiment, the difference is that: the first cover flip linkage mechanism 13 and the second cover flip linkage mechanism 14 of this embodiment cancel the left and right inner tension springs 46, 36. In this embodiment, the left and right outer limit plates 372 and 371 are used to replace the left and right inner tension springs 46 and 36 in the first embodiment. After the first and second overturning cover plates 41, 31 are turned into the storage chamber 11 of the coffee table, the left and right first connecting rods 42, 32 will rotate downwards and abut against the left outer limiting plate 372 and the right outer limiting plate respectively. On the limiting plate 371, under the action of the left and right outer limiting plates 372, 371, the left and right first connecting rods 42, 32 will stop turning downward. When the first and second f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com