Cavity type heating cigarette with reconstituted tobacco

A technology for reconstituted tobacco leaves and cigarettes, applied in the field of cavity heating cigarettes, can solve problems such as poor consumer experience and satisfaction, complex processing technology, and poor consumer smoking experience, and reduce burning sensation and irritation , solve the effect of excessively high smoke temperature and improve the smoking experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be noted that the implementations involved in this specification are not exhaustive, and do not represent the only implementations of the present invention. The following corresponding examples are only for clearly illustrating the content of the invention of the patent of the present invention, and are not intended to limit its implementation. For those of ordinary skill in the art, on the basis of the description of these embodiments, various changes and modifications can also be made, and any changes or modifications that belong to the technical concept and content of the present invention and are obvious are also included in the present invention. within the scope of protection.

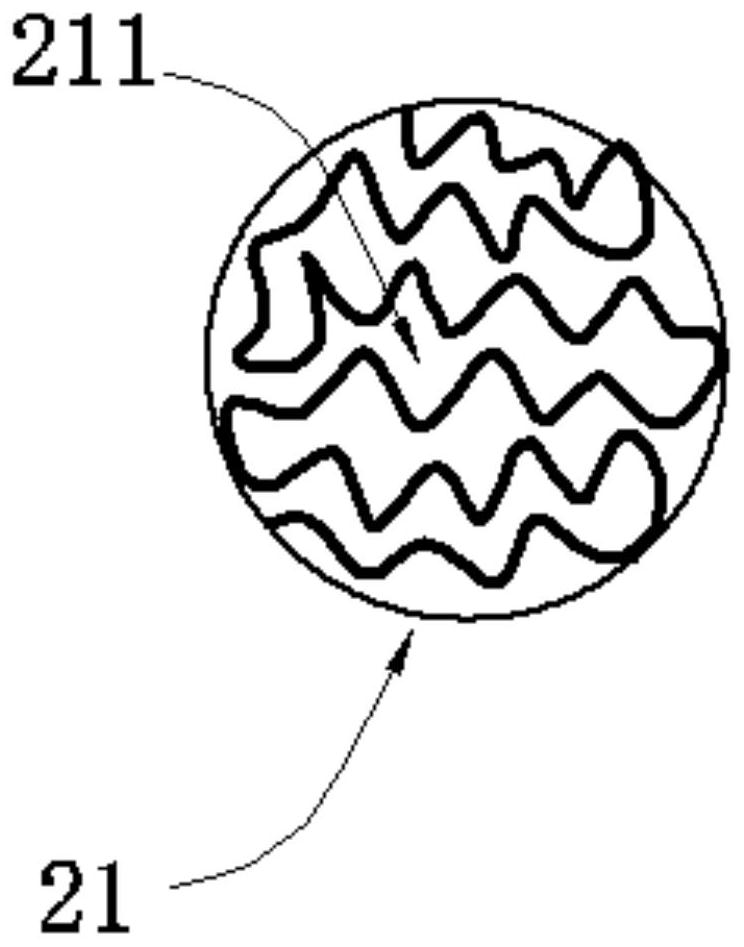

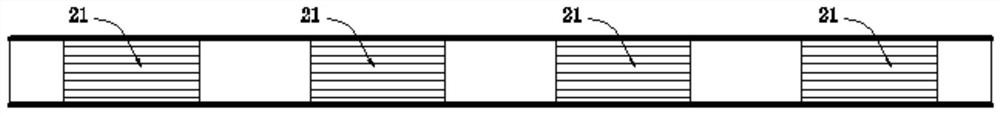

[0028] The names of the parts represented by the symbols in the drawings of the manual are as follows:

[0029] 1-tobacco segment; 2-reconstituted tobacco core filter rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com