Day-night complementary type soil heating system

A heating system and complementary technology, applied in the field of soil heating system, can solve the problems of single-stage solar heating system not being able to continuously supply heat for a long time, unable to continue heating at night, etc., to achieve the effect of avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

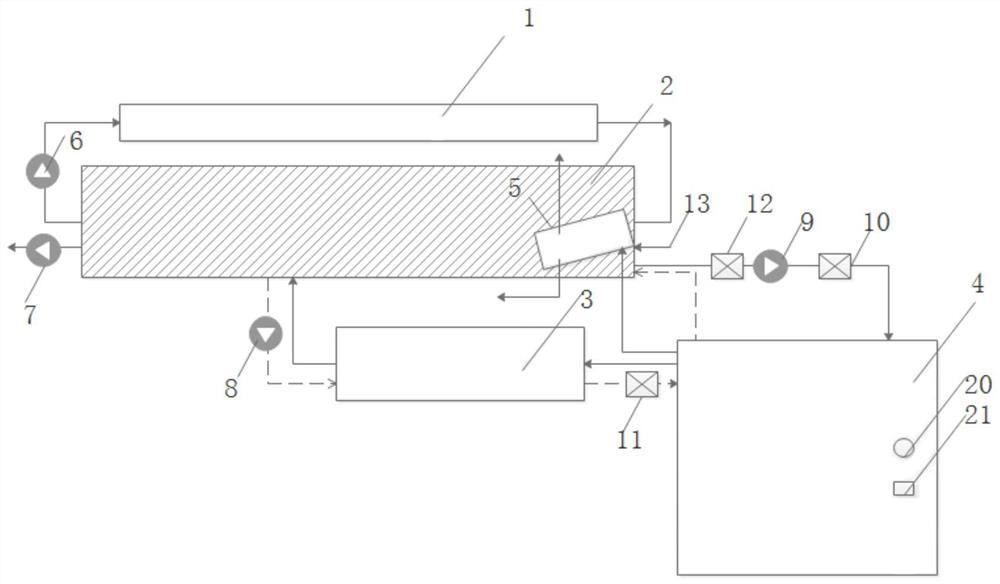

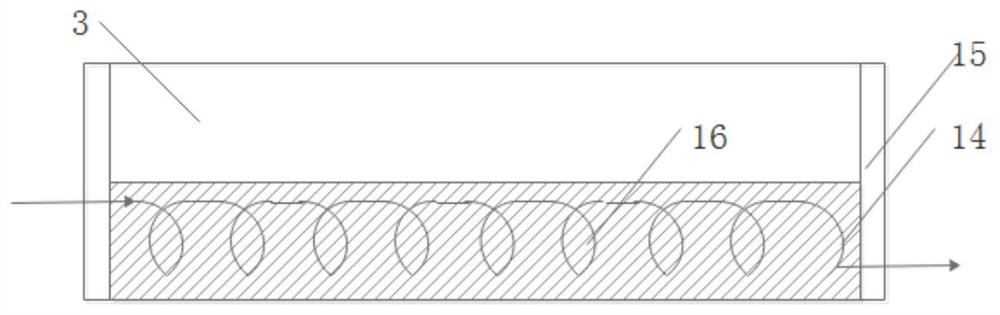

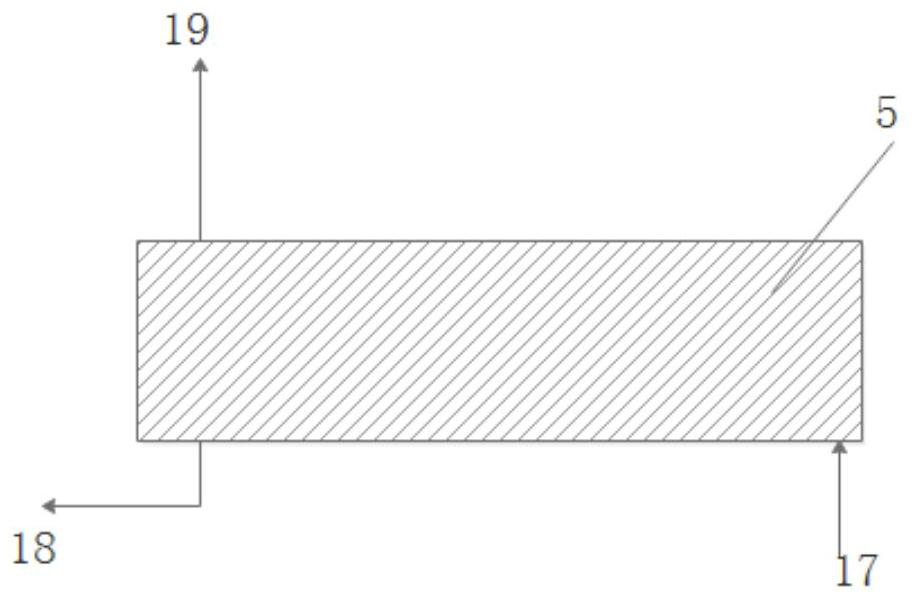

[0024] Specific implementation mode one: see Figure 1-3 This embodiment will be described. The day and night complementary soil heating system described in this embodiment includes a solar collector 1, a heat storage tank 2, a phase change material device 3, a fermentation tank 4, a high temperature container heat exchange device 5, a solar water inlet pump 6, and an underground water inlet pump 7. Water inlet pump 8 at night and water inlet pump 9 during the day; the high-temperature container heat exchange device 5 is arranged in the heat storage tank 2, and one end of the daytime water inlet pump 9 is connected to the heat storage tank 2, and the other end is connected to the fermentation tank 4. The pool 4 is connected to the phase change material device 3 through a pipeline, and the phase change material device 3 is connected to the heat storage tank 2 through a pipeline to form a circuit. The material device 3 is connected to the fermentation tank 4 through a pipeline,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com