Wide and thick plate ruler placing length optimization method based on data driving

A data-driven technology for measuring the length of a ruler, applied in the field of steel production, can solve the problems of restricting the yield of rolled steel, difficult maintenance, and waste of steel, so as to improve the yield, reduce maintenance, and reduce waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] This embodiment provides a data-driven method for optimizing the scale length of wide and heavy plates. Taking a single-stand wide and heavy plate rolling mill as the research object, the scale length of its production process is optimized. The process parameters of rolling equipment and products are as follows : Rolling mill type: single-stand four-high rolling mill; work roll length: 5000mm; work roll diameter range: 900-1150mm; billet thickness: 300mm; plane shape control: the control system has the plane shape control function.

[0016] ① Extract data, determine the key factors affecting the length of the ruler and its upper and lower limits

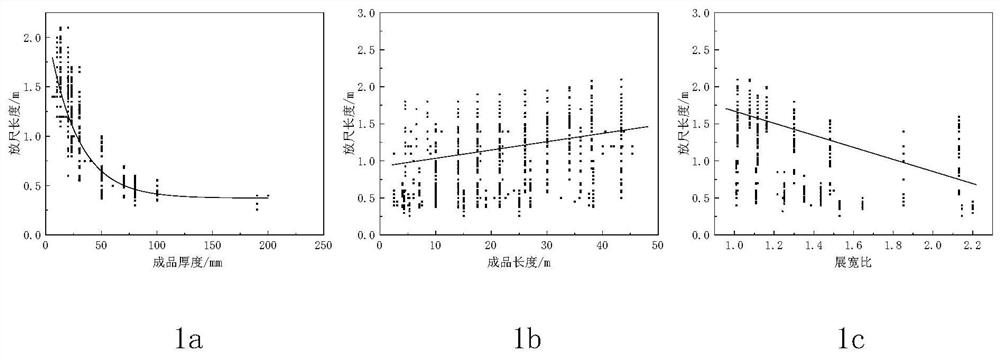

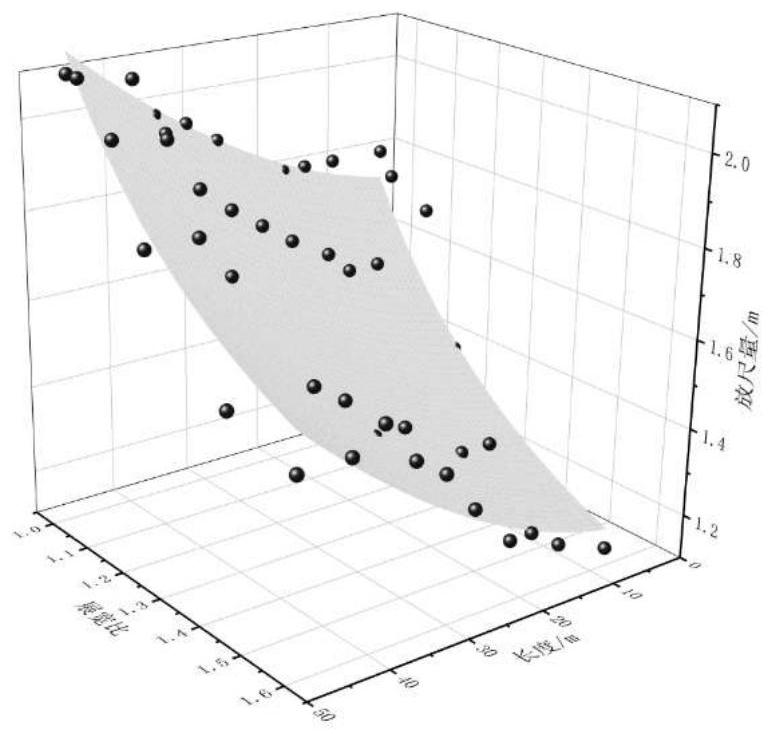

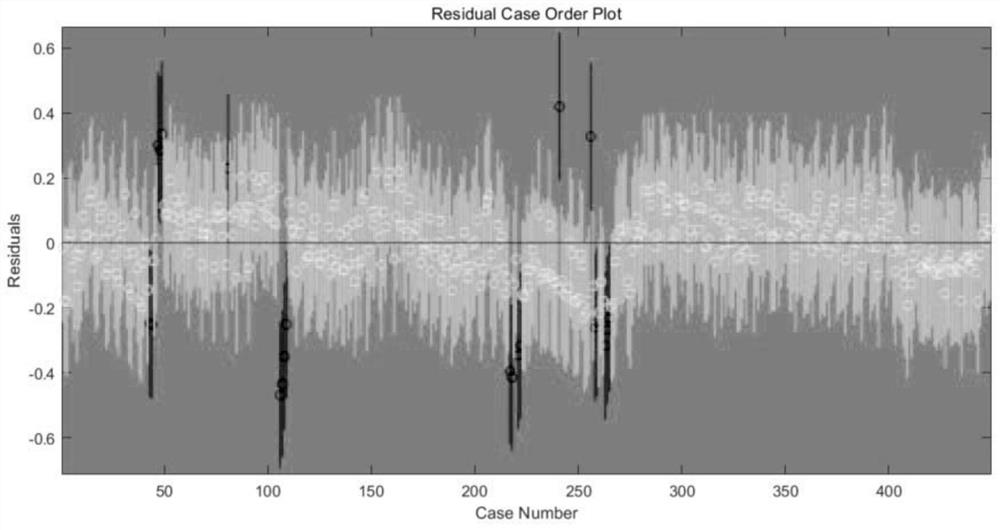

[0017] According to the three key factors of the thickness of the finished product, the length of the finished product and the width ratio, the corresponding length data of the scale is extracted from the scale layer table of the current production application, such as figure 1 shown. A total of 449 groups of initial data wer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com