Migration amount detection device for food packaging material

A technology for food packaging and detection devices, which is used in measurement devices, analytical materials, instruments, etc. to ensure stability and prevent double folding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

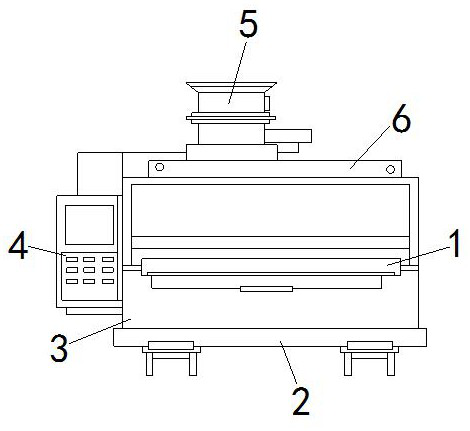

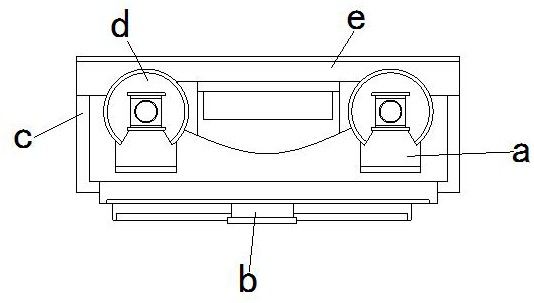

[0027] see Figure 1-Figure 4 , the present invention provides a technical scheme of a migration amount detection device for food packaging materials: its structure includes: a sample box 1, a base 2, a loading box 3, a controller unit 4, a detection head device 5, a moving frame 6, and the detection head The device 5 is installed above the moving frame 6 and locked with the moving frame 6, the moving frame 6 is arranged above the sample box 1, the sample box 1 is fastened to the moving frame 6, and a loading box is arranged below the sample box 1 3. A base 2 is provided under the loading box 3, and the base 2 is locked to the loading box 3. A controller unit 4 is provided on the side of the detection head device 5 and is electrically connected to the controller unit 4. The sample The box 1 includes a detection frame device a, a pull groove b, an isolation frame c, a cover plate d, and a slide rail plate e, the cover plate d is installed above the detection frame device a and ...

no. 2 example

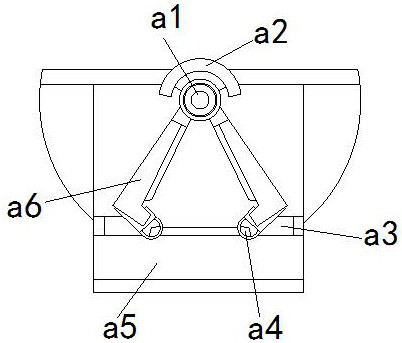

[0032] see Figure 5-Figure 7 , the present invention provides a technical scheme of a migration detection device for food packaging materials: its structure includes: the positioning groove device a3 includes an anti-roll block a31, a clamping block a32, and a supporting inner plate a33, and the anti-roll block a31 is installed Inside the clamping block a32, a supporting inner plate a33 is provided on the middle side of the clamping block a32, and the supporting inner plate a33 is locked with the clamping block a32.

[0033]The anti-roll block a31 includes an arc bar a311, a hinge spring a312, and an embedded hole groove a313. The arc bar a311 is installed above the hinge spring a312 and fastened with the hinge spring a312. The hinge spring a312 is arranged on At the bottom of the embedding hole a313, the anti-roll block a31 is pressed into the embedding hole a313 when the arc bar a311 is pressed by the cooperation of the hinge spring a312.

[0034] The pressing arm device a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com