Wind power blade

A technology of wind power blades and blade bodies, applied in the field of wind power blades, can solve the problems of poor flexibility, difficult processing, inconvenient disassembly and replacement of embedded bolts, etc., and achieve the effect of flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

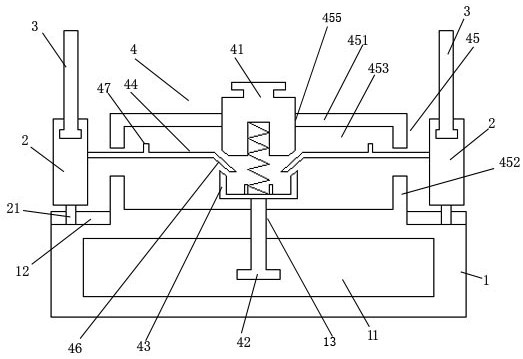

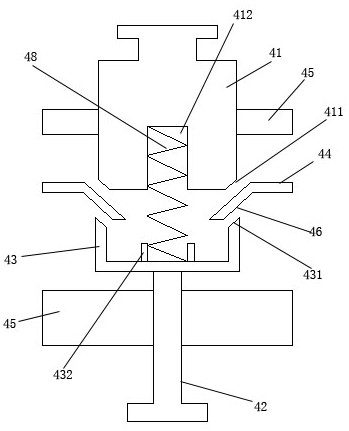

[0021] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0022] Such as Figures 1 to 5 As shown, a wind power blade includes a blade body, a blade root block 1, a radial floating mechanism 4, a radial sliding block 2, and a pre-embedded bolt 3; the root of the blade body is installed with a blade root block 1; the blade root The block 1 has a circular block structure; the inside of the blade root block 1 is provided with a driving cavity 11; the middle of the upper end of the driving cavity 11 is provided with a threaded channel 13; A plurality of sliding slots 12 radially distributed along the blade root block; a radial sliding block 2 is mounted on the sliding slots 12 for radial sliding engagement respectively; the upper ends of the radial sliding blocks 2 are respectively rotated and engaged A pre-embedded bolt 3 is installed; the radial floating mechanism 4 includes a driving chamber 45, a rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com