Novel climbing frame system

A new type of frame technology, which is applied to the accessories of scaffolding, the scaffolding supported by the building structure, the supporting structure of the building, etc. It can solve the problems of poor rigidity of the protective grid structure, inconvenient use of the unloading supporter, and inconvenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

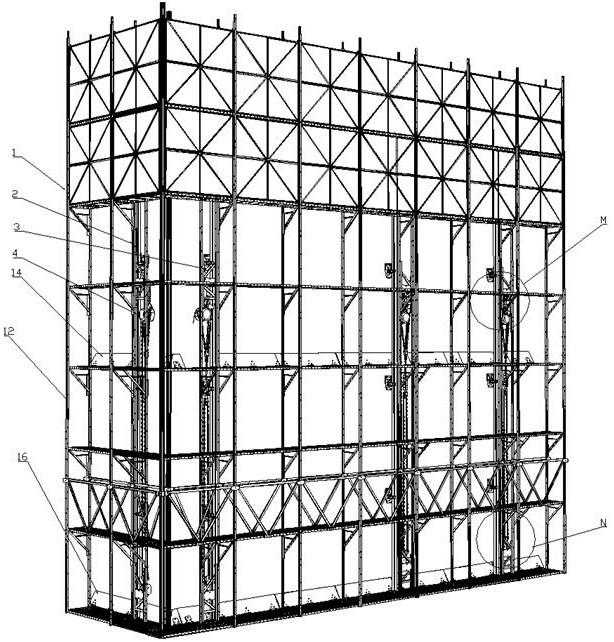

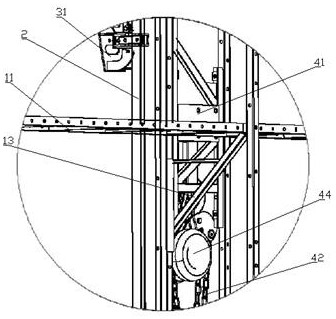

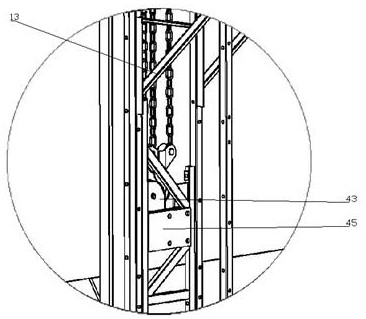

[0071] Such as Figure 1~Figure 25 , a novel climbing frame system of the present invention, which includes a frame body frame 1 for building construction, a guide rail 2 arranged on the frame body frame for moving guidance, and an attachment support fixed on the main body project and connected with the guide rail Module 3, and the lifting module 4 fixedly connected to the upper and lower parts of the guide rail for the frame to move up and down, and the control system electrically connected to the lifting module, one side of the single guide rail is provided with a lifting module, and the lifting module 4 includes Hanging point truss 41, tension adjustment device 42, lower hanging point truss 43, electric hoist 44 and wall hanging point 45. The device is set on the truss of the hoisting point, the electric hoist is set between the truss of the hoisting point and the truss of the lower hoisting point, the hanging point attached to the wall is set on the main project and connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com