Real-time pipeline replacement method and real-time pipeline replacement system for coke oven

A pipeline and coke oven technology, which is applied in the field of systems that can replace pipelines in real time, can solve the problems of prolonging the experiment period and difficult removal of semi-coke, and achieve the effects of improving experiment efficiency, reducing risks, and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

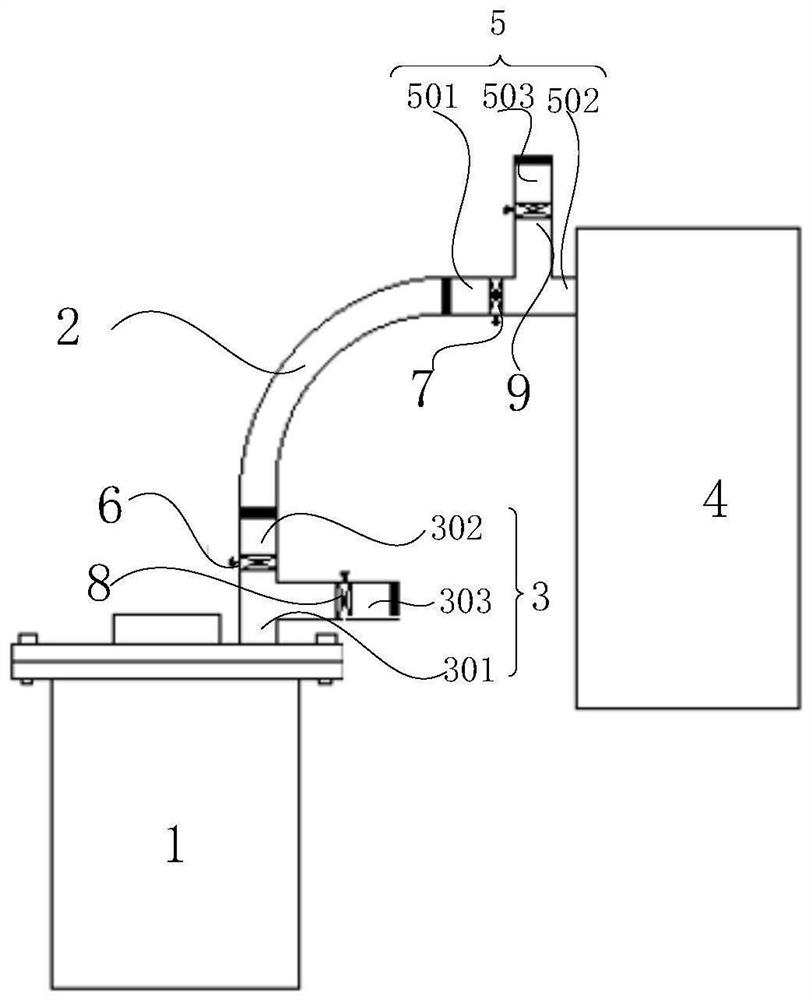

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0035] The embodiments of the present invention take the 40kg small coke oven as an example, the fluid generating device is the coal screen 1 of the coke oven heating furnace; the fluid receiving device is the gas cooler 4, and the experimental process of the 40kg small coke oven produces coal gas from the coal screen 1, and the gas To the gas cooler 4 for cooling.

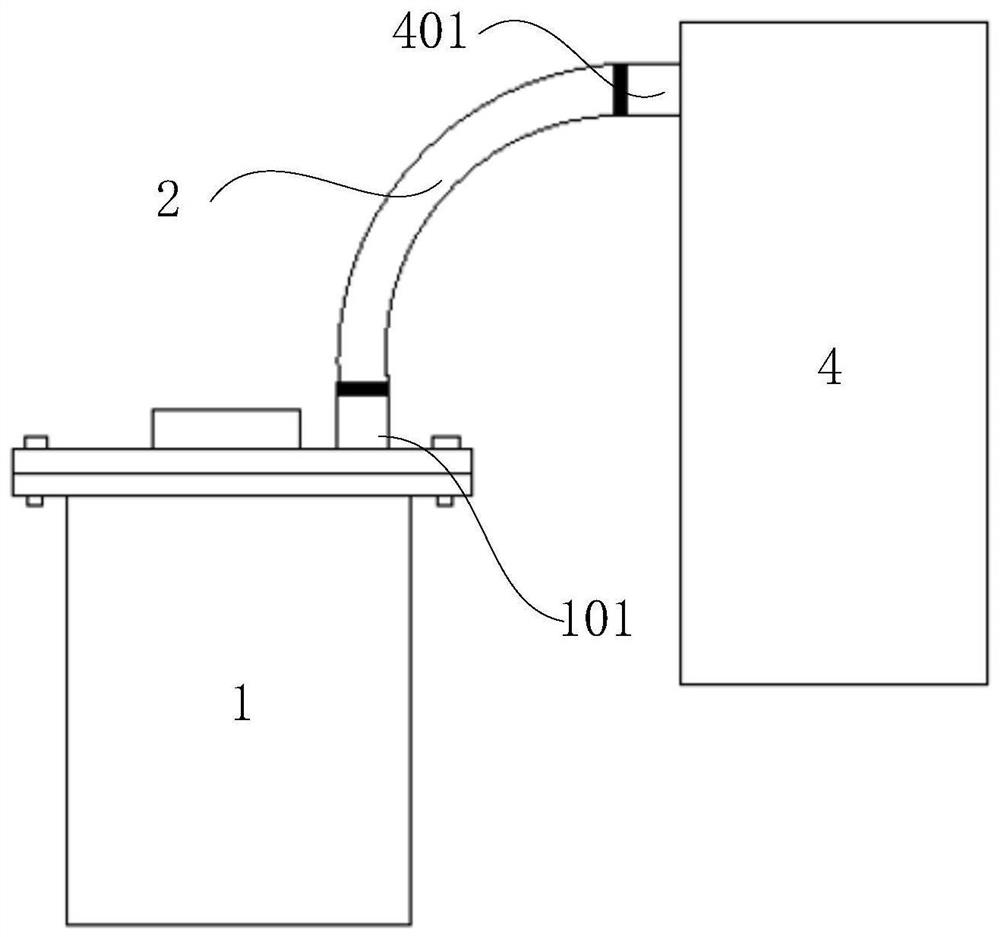

[0036] Such as figure 1 As shown, in the prior art, one end of the original pipeline 2 is connected to the gas outlet 101 of the coal mine 1, and the other end is connected to the gas inlet 401 of the gas cooler 4, and is tightened with a turnbuckle. During the experiment, when the original pipeline 2 gas leaks (such as corrosion and damag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com