Washing device for optical communication chip production

A cleaning device and chip cleaning technology, which is applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of low cleaning efficiency and achieve the effect of improving cleaning efficiency and facilitating collection and arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

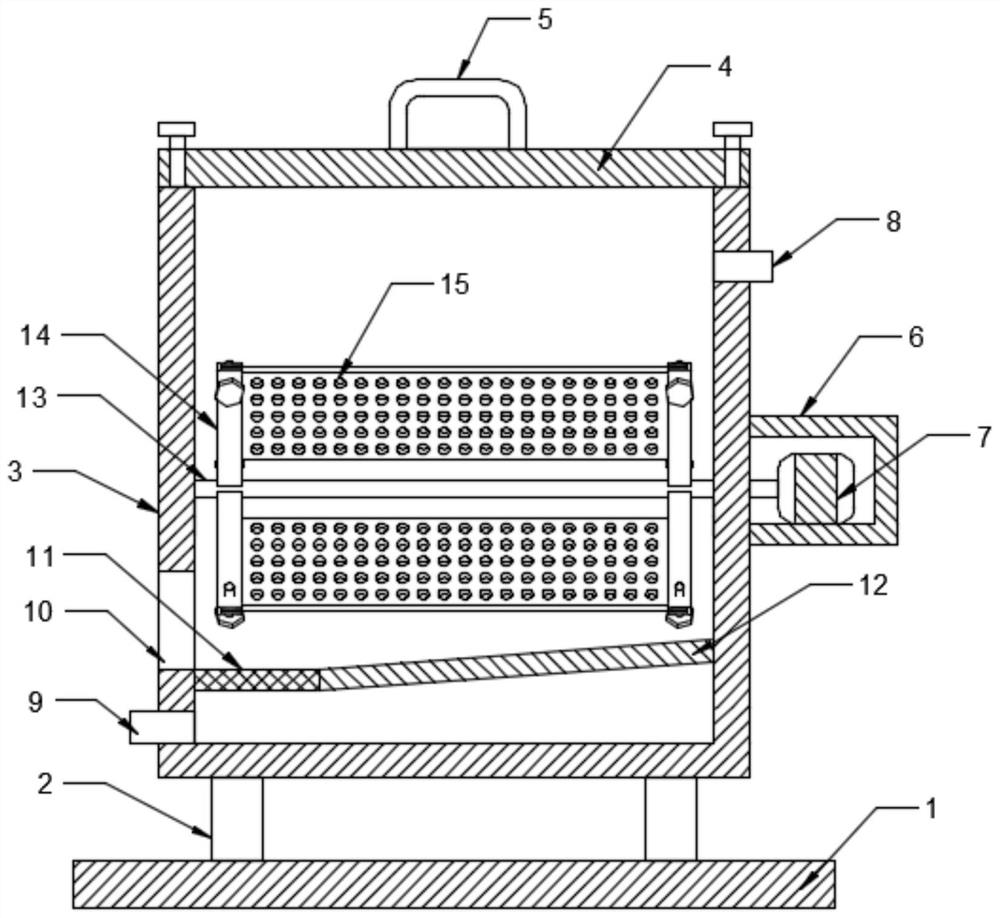

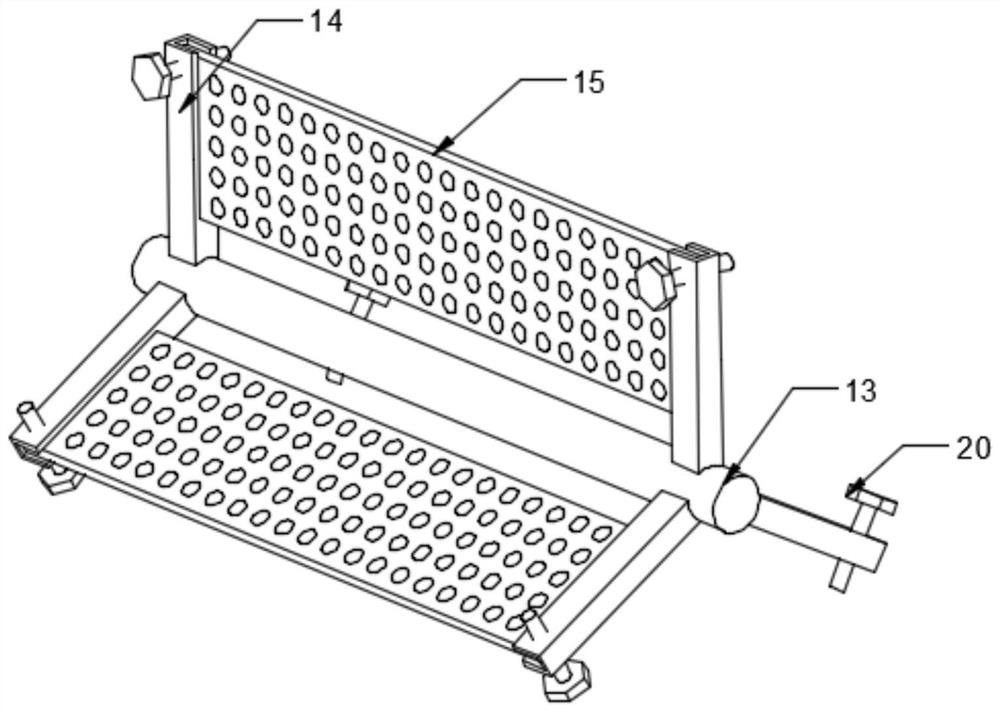

[0025] see Figure 1-5 , a cleaning device for optical communication chip production, comprising a base plate 1, a support column 2 and a cleaning frame 3, a water inlet 8 is provided on one side of the cleaning frame 3, and the cleaning frame 3 is provided with a chip cleaning assembly, and the chip cleaning assembly The specific type is not limited. In this embodiment, preferably, the chip cleaning assembly includes a protective frame 6, a drive motor 7, and a rotating shaft 13. The driving motor 7 is installed in the protective frame 6 and the output end is driven and connected to one end of the rotating shaft 13. The rotating shaft 13 is rotatably installed in the cleaning frame 3 and there are multiple groups of chip placement components arranged on the periphery. The specific type of the chip placement components is not limited. In this embodiment, preferably, the chip placement components include a fixed rod 14 and a placement plate 15 , fastening bolts 20, installation...

Embodiment 2

[0034] In order to improve the practicability, this embodiment is further improved on the basis of embodiment 1. The improvement is that: a repeated cleaning component is arranged under the cleaning frame 3, and the specific type of the repeated cleaning component is not limited. In this embodiment , preferably, the repeated cleaning assembly includes a cleaning door 10, a filter screen 11, a deflector 12, a nozzle 17, a water pipe 18 and a water pump 19, and the deflector 12 is installed obliquely in the cleaning frame 13 and between the low end and the cleaning frame 3 A filter screen 11 is arranged between them, a water pump 19 is installed at the bottom of the cleaning frame 3 and is connected with a nozzle 17 through a water pipe 18, the nozzle 17 is located on the side wall of the cleaning frame 3 and facing the placement plate 15, and the cleaning door 10 is opened on the filter On the side of the net 11, during the cleaning process, the cleaning liquid passes through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com