Stirring type bovine collagen low-fat yoghourt and processing method

A bovine collagen and stirring technology, which is applied in milk preparations, dairy products, applications, etc., can solve the problems of low fat content of low-fat yogurt, weak enjoyment, strong graininess, etc., to achieve a strong sense of fat and improve nutrition. Value, thick taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Bovine collagen low-fat yogurt formula composition: 90 parts of low-fat milk, 0.5 parts of bovine collagen powder (mesh greater than 80 mesh), 8 parts of white sugar (mesh greater than 20 mesh), strains (Streptococcus thermophilus, Bulgaria Lactobacillus) 0.001 part.

[0030] (1) Acceptance of low-fat milk, cooling;

[0031] (2) Pour the bovine collagen powder and white granulated sugar into the mixing tank after fully dry mixing the formula amount, fully mix with low-fat milk, and constant volume;

[0032] (3) Heating, homogenization, pasteurization, cooling: homogenization pressure 180±20bar, sterilization temperature 95°C, time 300s, cooling to 42°C;

[0033] (4) inoculation, fermentation, terminal acidity 80 ° T;

[0034] (5) Stirring, cooling and filling;

[0035] (6) According to the desired taste, you can add 1 part of dried blueberries, 2 parts of yellow peach pieces, etc., and fill them with yogurt;

Embodiment 2

[0037] Bovine collagen low-fat yogurt formula composition: 90 parts of low-fat milk, 0.9 parts of bovine collagen powder (mesh greater than 80 mesh), 8 parts of white sugar (mesh greater than 20 mesh), strains ((Streptococcus thermophilus, Lactobacillus bulgaricus) 0.001 part.

[0038] (1) Acceptance of low-fat milk, cooling;

[0039] (2) Pour the bovine collagen powder and white granulated sugar into the mixing tank after fully dry mixing the formula amount, fully mix with low-fat milk, and constant volume;

[0040] (3) Heating, homogenization, pasteurization, cooling: homogenization pressure 180±20bar, sterilization temperature 95°C, time 300s, cooling to 42°C;

[0041] (4) inoculation, fermentation, terminal acidity 80 ° T;

[0042] (5) Stirring, cooling and filling;

[0043] (6) According to the desired taste, you can add 1 part of dried blueberries, 2 parts of yellow peach pieces, etc., and fill them with yogurt;

Embodiment 3

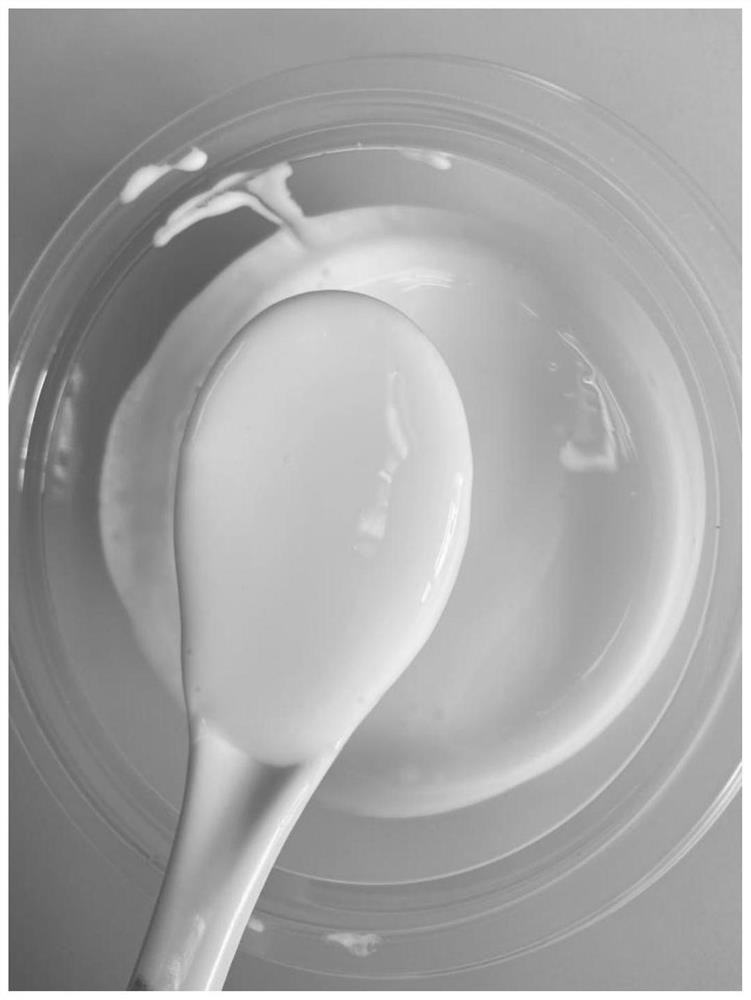

[0045] Such as figure 1 As shown, the low-fat yogurt added with 0 parts of bovine collagen has a thin texture and light aroma, and whey precipitates after being left for a long time. Such as figure 2 , image 3 As shown, the low-fat yoghurt added with bovine collagen of the present invention has a strong aroma and a fine and smooth mouthfeel. image 3 Compare figure 2 Yogurt has a firmer texture and can be eaten with a spoon, making it a highly enjoyable product. Such as figure 2 , image 3 The product has no whey precipitation during the shelf life, and it is a very high-quality product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com