High-voltage line deicing device

A technology of high-voltage wires and shells, which is applied in the field of robots, can solve the problems of poor deicing effect, achieve the effect of solving poor deicing effect, improving impact force, and realizing efficient deicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

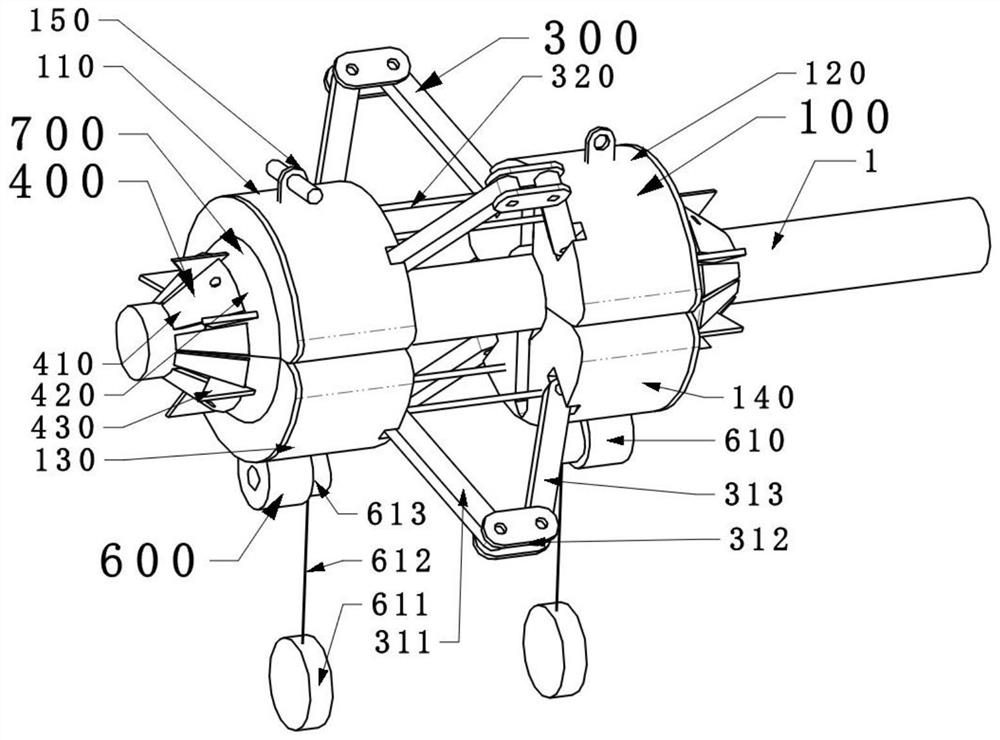

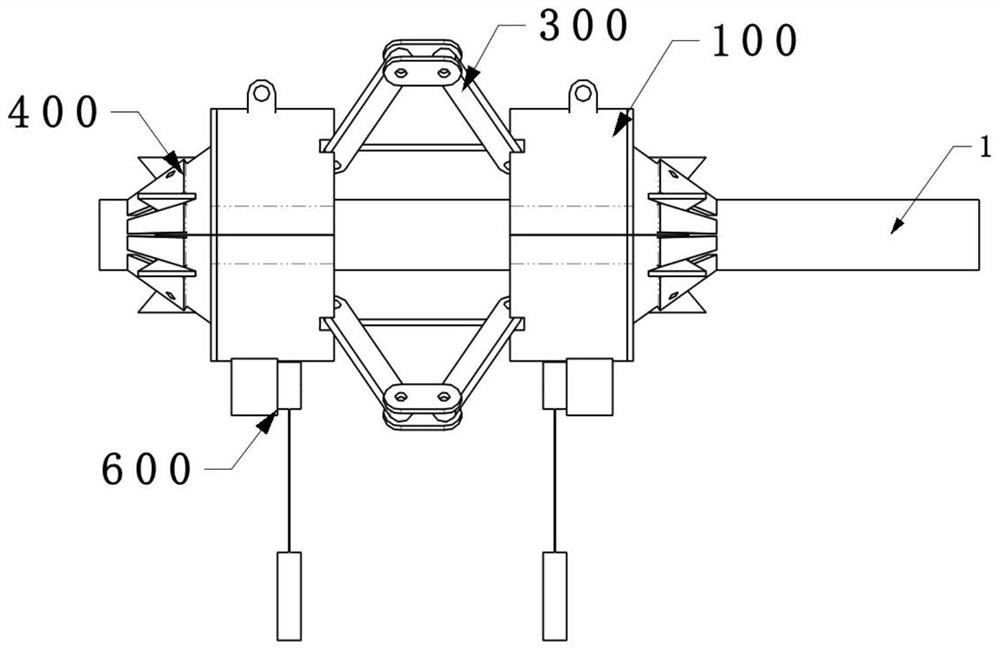

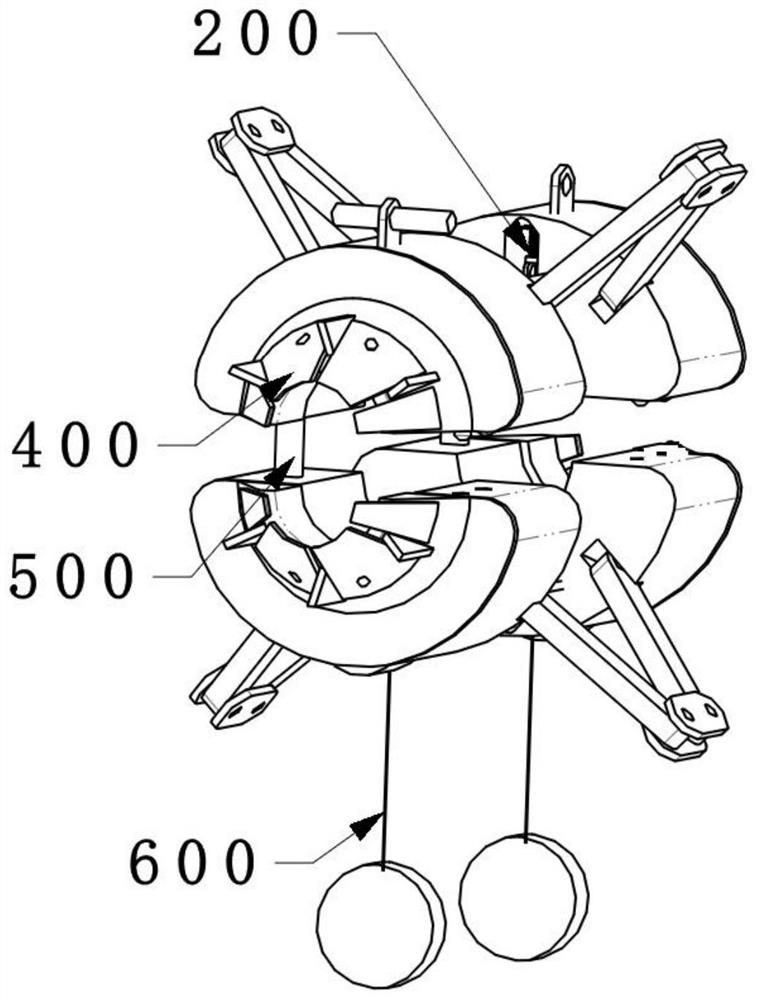

[0098] like figure 1 As shown, the high-voltage line deicing device of the present application includes a housing 100, a travel assembly 200, a power storage assembly 300, a deicing assembly 400, an upper line assembly 500, an energy supply assembly 600 and a control assembly.

[0099] like figure 1 or 2, the housing 100 is used to carry other components of the high-voltage line deicing device, which includes an upper housing and a lower housing; the upper housing includes a first upper housing 110 and a second upper housing 120, the first upper case 110 and the second upper case 120 have the same structure, both are arc-shaped plates, the two are arranged symmetrically, and are connected through the power storage assembly 300; the first upper case 110 It coincides with the axis of the second upper casing 120 and the axial direction of the two is the same as the axial direction of the high-voltage line 1; the upper casing and the lower casing have the same structure and are s...

Embodiment 2

[0118] In order to further enhance the deicing effect of the high-voltage line deicing device of this application, this embodiment adds a rotating assembly 700 on the basis of the first embodiment, and speeds up deicing by controlling the rotation of the deicing assembly 400 around its own axis.

[0119] like Figure 7 or Figure 8 As shown, the rotating assembly 700 includes a half ring gear 710, a ring gear rotating assembly 720, a ring gear support 730, and a rotation locking assembly 740; the half ring gear 710 is fixedly connected to the ice shovel positioning bracket 420 , the number of half ring gears 710 is 2, and the structure of the two half ring gears 710 is exactly the same, and the two can form a complete ring gear; the half ring gear 710 includes a first half ring gear 711 and a second half ring gear ring 712; the ring gear rotation assembly 720 is used to drive the ring gear composed of the half ring gear 710 to rotate, further, the ring gear rotation assembly ...

Embodiment 3

[0125] Considering that the device of the present application may rotate around the axis of the high-voltage line 1 during practical application (moving on the high-voltage line 1), causing the lifting assembly 150 to be deflected, which is not conducive to (unmanned aerial vehicle) lifting Transport, in order to reduce the difficulty of lifting, the described lower casing is also provided with a counterweight.

[0126] Preferably, in order to improve the battery life of the device of the present application, the energy supply assembly 600 further includes a sway power generation assembly, and the sway power generation assembly 610 is positioned on the first lower casing 130 and / or the second lower casing On the body 140, it plays the role of counterweight while generating electricity.

[0127] Further, the shaking power generation assembly 610 includes a weight 611, a suspension rope 612 and a power generation unit 613; one end of the suspension rope 612 is positioned on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com