Monofilament anchoring test device and detection method thereof

A technology of test device and detection method, which is applied in the direction of measuring device, specific gravity measurement, and testing the strength of materials by applying stable tension/pressure, which can solve the problems of test value error, difficulty in ensuring the coaxiality of steel wire and steel pipe, and steel wire inclination. , to achieve the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

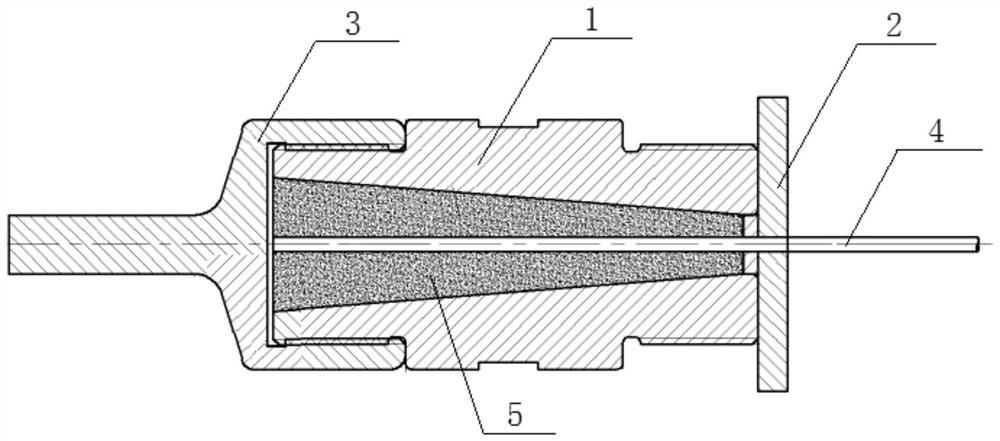

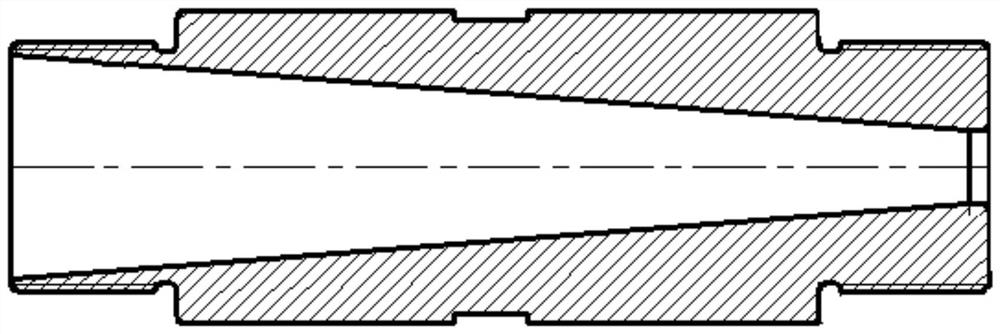

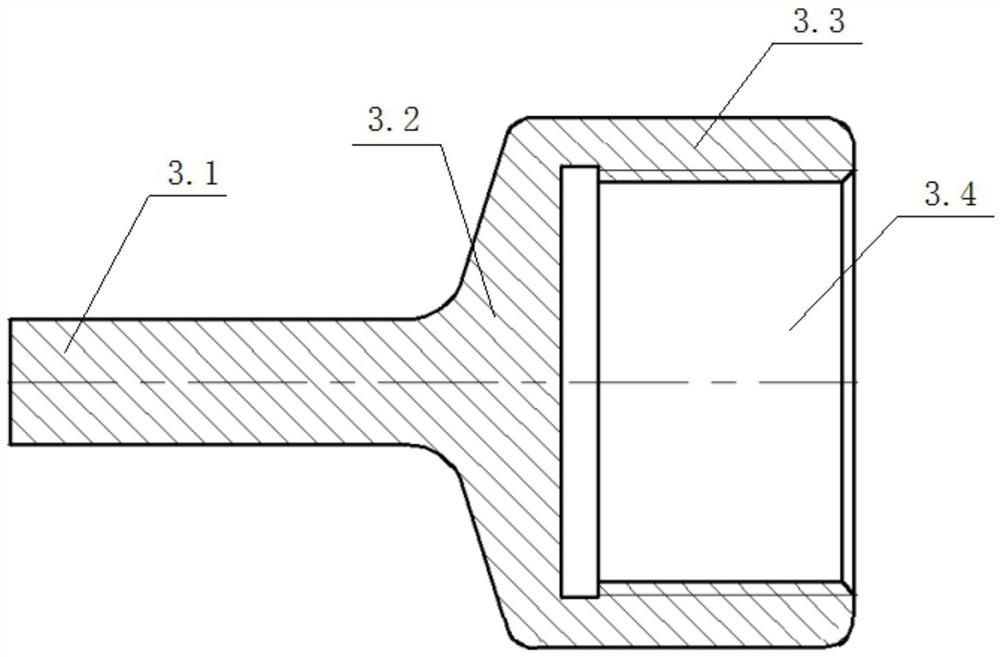

[0024] Such as figure 1 , 2 , 4, a monofilament anchoring test device in this embodiment includes a monofilament anchor cup 1, a through hole is opened in the center of the monofilament anchor cup 1, and the cross section of the through hole is tapered, and the large diameter end of the through hole A connecting sleeve 3 is provided, and an external thread is provided on the outer circumference of the large-diameter end of the through hole of the monofilament anchor cup 1, so that the connecting sleeve 3 is threadedly connected with one end of the monofilament anchor cup 1. The small-diameter end of the through hole is provided with a sealing cover plate 2, and the center of the sealing cover plate 2 is provided with a boss 2.1. The other end of the anchor cup 1 has a sealing function. A threading hole 2.2 is provided in the center of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com