Anti-logic proportional valve and vane pump variable control system

A proportional valve and inverse logic technology, applied in the direction of pump control, lubricating oil control valve, sliding valve, etc., can solve problems such as complex structure, and achieve the effect of simple structure installation, good stability, and easy guarantee of hole precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

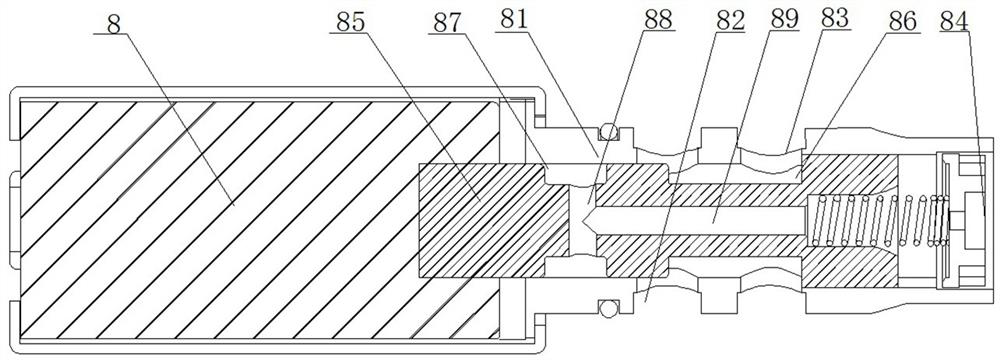

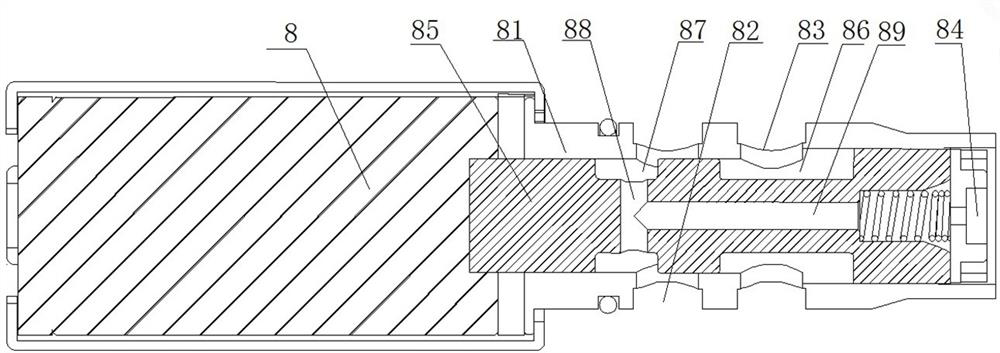

[0032] like figure 1 , 2 As shown, an inverse logic proportional valve, the inverse logic proportional valve 8 includes a valve body 81, a plunger 85 and a spring, the valve body 81 is provided with a valve hole for accommodating the plunger 85 and the spring, and the valve body 85 is provided with a communicating valve hole A port 82, P port 83 and T port 84; the outer peripheral surface of the plunger 85 is provided with a first annular oil groove 86, the first annular oil groove 86 can make the A port 82 and P port 83 intercommunication; the cross-sectional area of the groove wall of the first annular oil groove 86 close to the spring is larger than the cross-sectional area of the other side, thereby forming an area difference; a second annular oil groove 87 is also provided on the plunger 85 of the first annular oil groove 86 away from the spring , the second annular oil groove 87 can communicate with port A 82 in the open state of the inverse logic proportional valve...

Embodiment 2

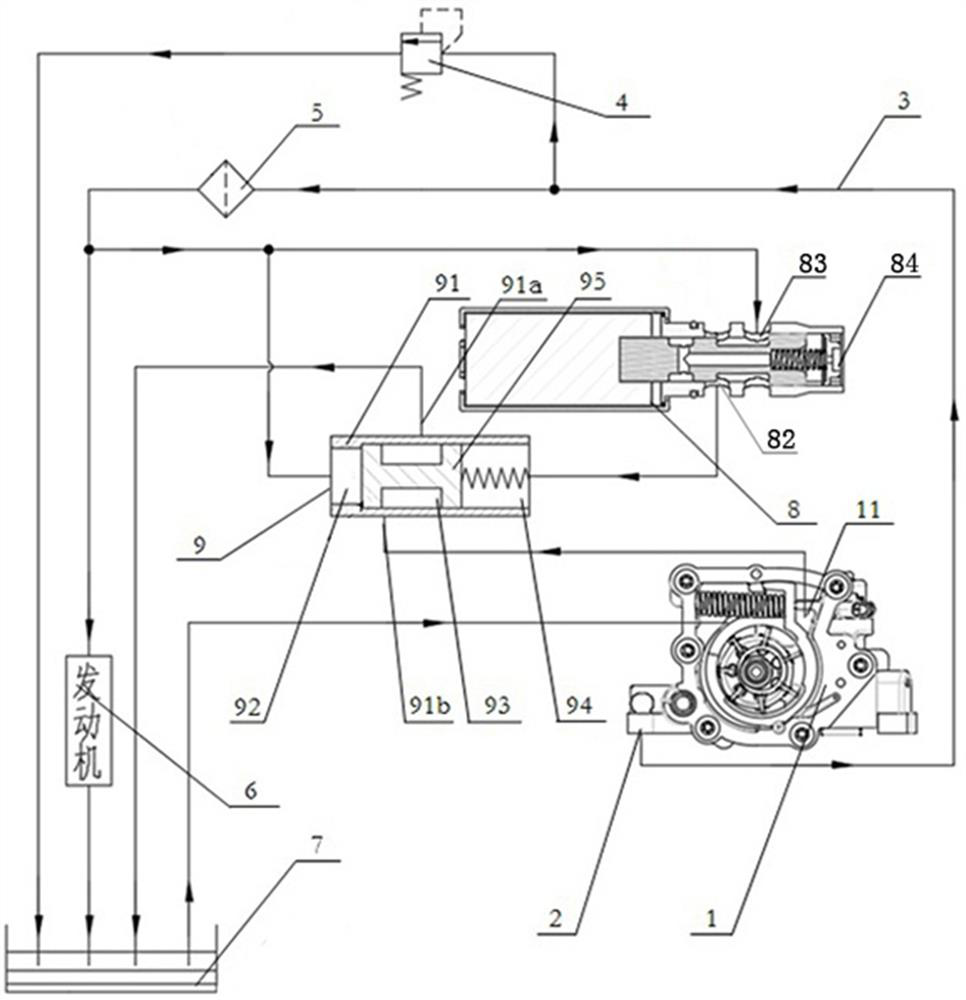

[0034] like Figures 1 to 4 As shown, a vane pump variable control system includes a vane pump 1, an oil outlet 2, a main oil passage 3, an oil pan 7 and a mechanical valve 9. The vane pump 1 includes a pump body, a feedback pressure oil chamber 11, a rotor and Variable slider; the control system also includes an inverse logic proportional valve 8, the inverse logic proportional valve 8 includes a valve body 81, a plunger 85 and a spring, the valve body 81 is provided with a valve hole for accommodating the plunger 85 and the spring, and the valve body 85 is set There are A port 82, P port 83 and T port 84 communicating with the valve hole; the outer peripheral surface of the plunger 85 is provided with a first annular oil groove 86, and the first annular oil groove 86 can make the A port 82 communicates with P port 83; the cross-sectional area of the groove wall of the first annular oil groove 86 close to the spring is larger than the cross-sectional area of the other sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com