Header with elliptical necking end socket and manufacturing method thereof

A manufacturing method and header technology, applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of unqualified welds, high safety risks, etc., and achieve the effect of avoiding falling off, avoiding possibility, and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, and its content is explanation of the present invention rather than limitation:

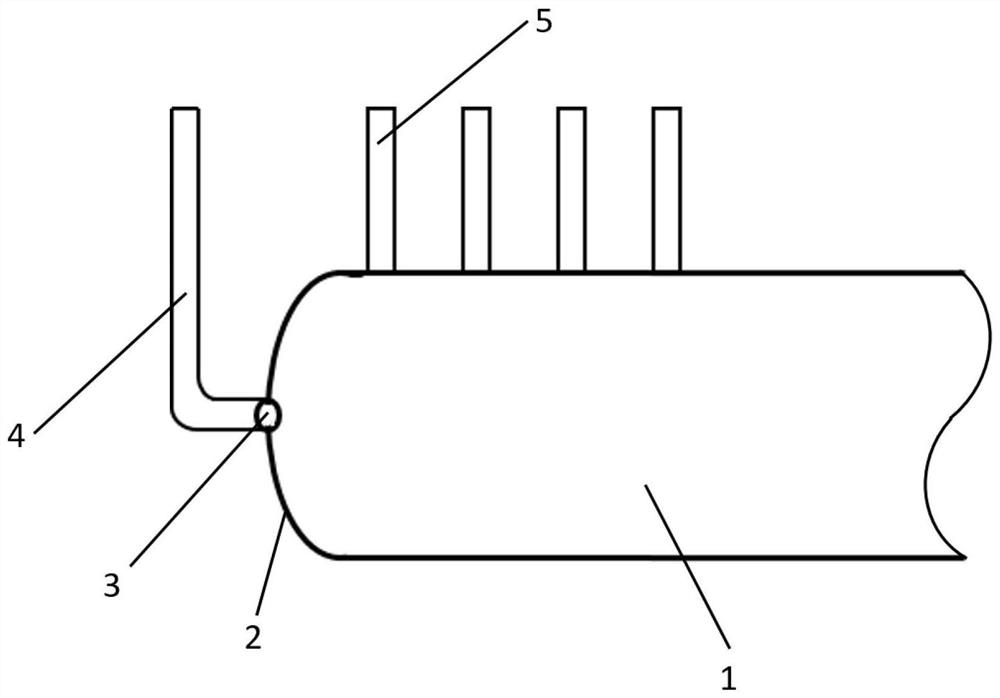

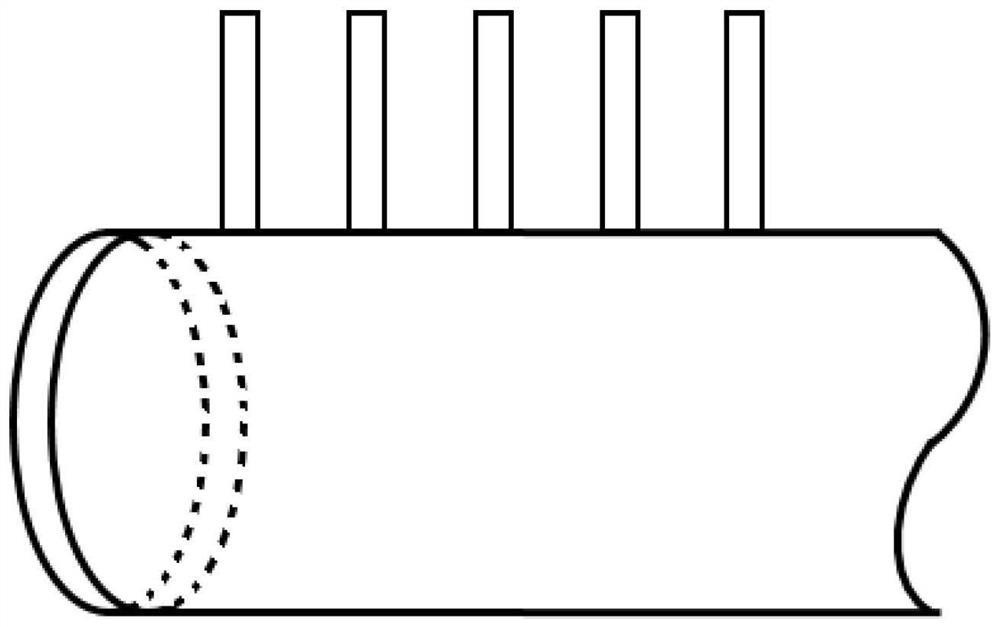

[0030] Such as figure 1 , the header with an elliptical necking head of the present invention includes a header cylinder 1, one end of the header cylinder 1 is thermally spun to form an elliptical necking head 2, and the outer diameter of the header cylinder 1 is generally selected 160 ~ 350mm, wall thickness ≤ 30mm, on the one hand, this size specification is easy to extrude after the header cylinder is heated, on the other hand, it can ensure the reliability of the equipment strength after molding; the thickness of the elliptical necking head 2 is generally designed as the header cylinder 90% to 100% of the wall thickness of the body 1, to avoid excessively weak parts that affect the strength. A shrinkage hole 3 is left on the elliptical shrinkage head 2, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com