Summer road pressure reduction and maintenance device

A technology for roads and pipelines, which is applied in the field of summer road decompression maintenance devices, which can solve problems such as limited cooling effect, large water spraying range, and road damage, so as to improve the convenience of installation, improve the maintenance effect, and ensure the air extraction effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

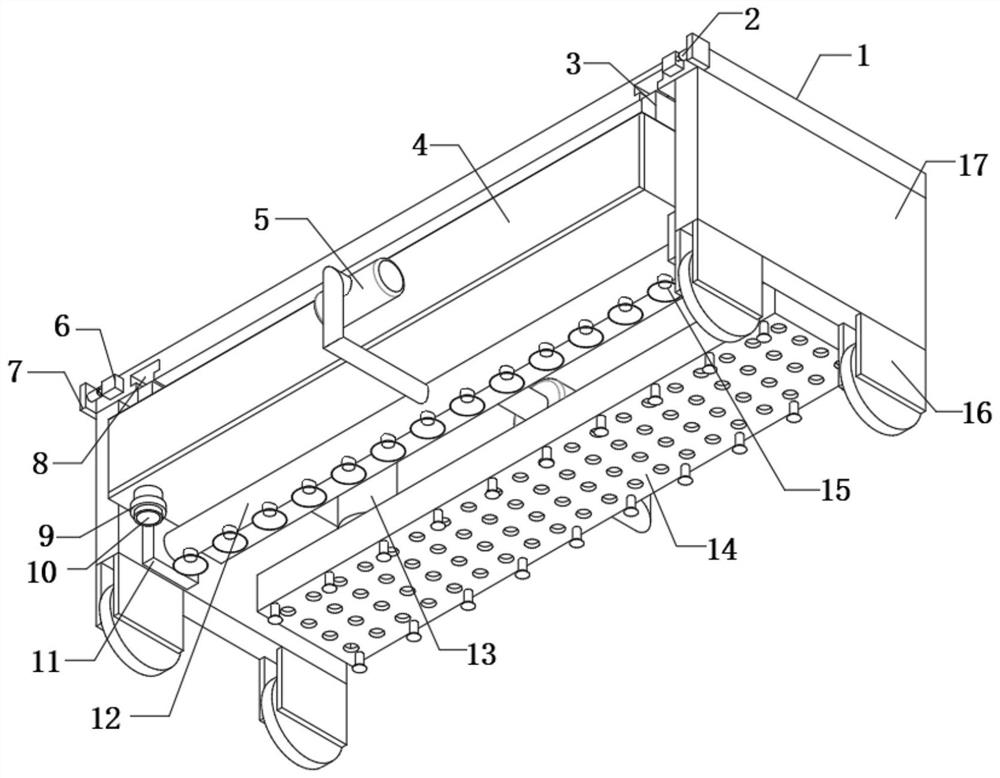

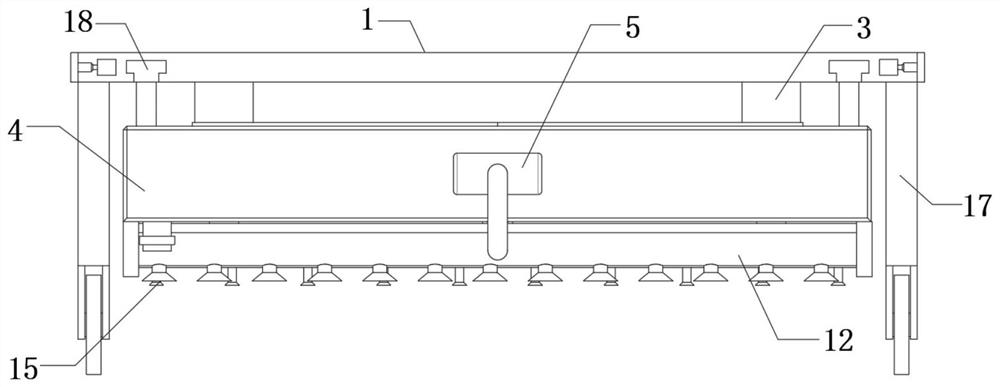

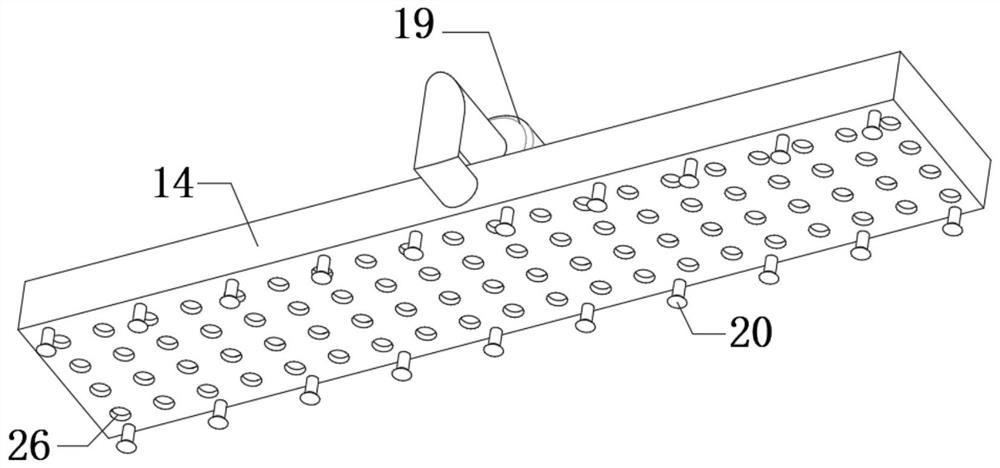

[0028] refer to Figure 1-4 , a summer road depressurization maintenance device, comprising a fixed plate 1, the bottom outer wall of the fixed plate 1 is fixedly connected with two cylinders 13, and the bottom outer walls of the two cylinders 13 are fixedly connected with the same air plate 14, the air plate 14 The top outer wall is fixedly connected with an air suction pump 19, and the suction end of the air suction pump 19 is connected to the inside of the air plate 14 through a pipeline, and the equidistant distances of the bottom outer wall of the air plate 14 have air holes 26, and the two ends of the bottom outer wall of the air plate 14 Ground blocks 20 are fixedly connected at equal distances, support plates 17 are fixedly connected to both ends of the bottom outer wall of the fixed plate 1 , and two universal wheels 16 are fixedly connected to the bottom outer walls of the two support plates 17 .

[0029] In the present invention, two sliding grooves 8 are formed on ...

Embodiment 2

[0038] refer to Figure 5 , a summer road depressurization maintenance device, comprising a fixed plate 1, the bottom outer wall of the fixed plate 1 is fixedly connected with two cylinders 13, and the bottom outer walls of the two cylinders 13 are fixedly connected with the same air plate 14, the air plate 14 The top outer wall is fixedly connected with an air suction pump 19, and the suction end of the air suction pump 19 is connected to the inside of the air plate 14 through a pipeline, and the equidistant distances of the bottom outer wall of the air plate 14 have air holes 26, and the two ends of the bottom outer wall of the air plate 14 Ground blocks 20 are fixedly connected at equal distances, support plates 17 are fixedly connected to both ends of the bottom outer wall of the fixed plate 1 , and two universal wheels 16 are fixedly connected to the bottom outer walls of the two support plates 17 .

[0039] In the present invention, two sliding grooves 8 are formed on on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com