Method for adding coal water slurry into thick black liquor for mixed combustion in alkali recovery furnace

A technology of mixed combustion and coal-water slurry, which is applied in the direction of pulping waste liquid combustion, etc., can solve the problems of insufficient concentrated black liquor, the inability of the alkali recovery furnace to exert its maximum efficiency, and the concentration of concentrated black liquor that cannot meet the requirements, so as to achieve increased The effect of burning volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

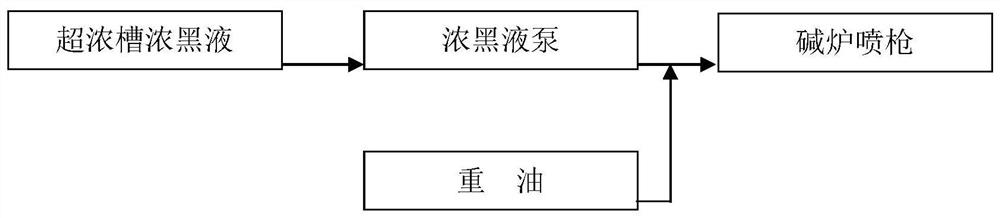

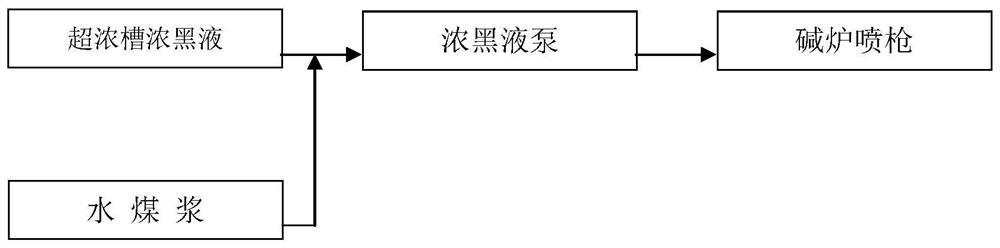

Method used

Image

Examples

Embodiment 1

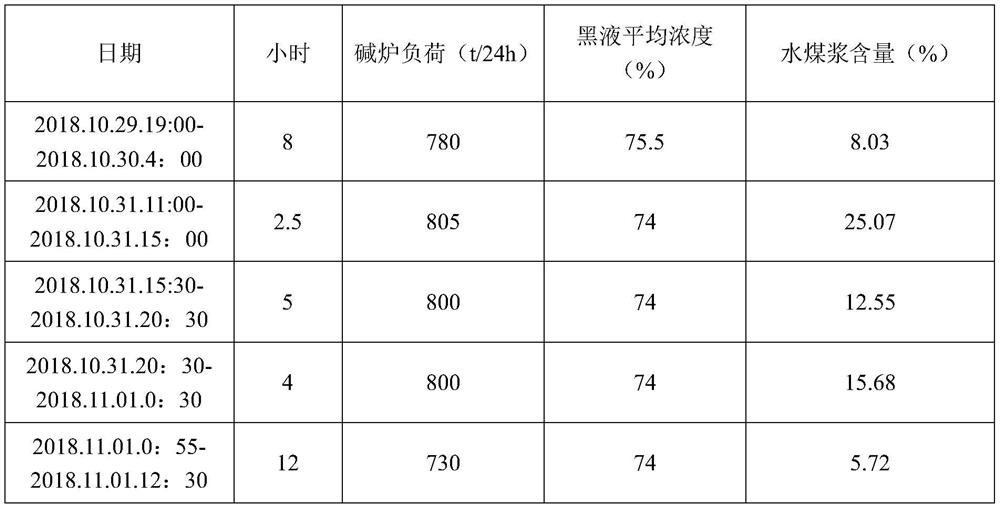

[0015] Because the black liquor has been super-concentrated, the concentration of the black liquor can generally reach the requirement of more than 60%. This invention mainly solves the problem that the black liquor is insufficient and the load of the alkali furnace cannot meet the requirements. Therefore, the coal water slurry and the thick black liquor are mixed in the alkali furnace burn in. The test results are as follows: During the test period, the total amount of coal-water slurry added: 292.48 tons, with an average concentration of 62.25%, a total of 14 vehicles, with an average of 20.89 tons per vehicle.

[0016] Table 1 CWS test data collection form

[0017]

[0018]

[0019] According to the data in Table 1, the content of coal water slurry entering the furnace is as low as 5.72% and as high as 25.07%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com