Preparation method of petroleum-based high softening point asphalt

A high softening point asphalt, petroleum-based technology, which is applied in the heating processing of tar asphalt/petroleum asphalt/natural asphalt, chemical processing of tar asphalt/petroleum asphalt/natural asphalt, petroleum industry, etc., can solve the performance degradation of negative electrode materials. , the reduction of the inherent physical properties of carbon and the high content of heteroelements, to achieve the effect of reducing the content of quinoline insolubles and increasing the capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

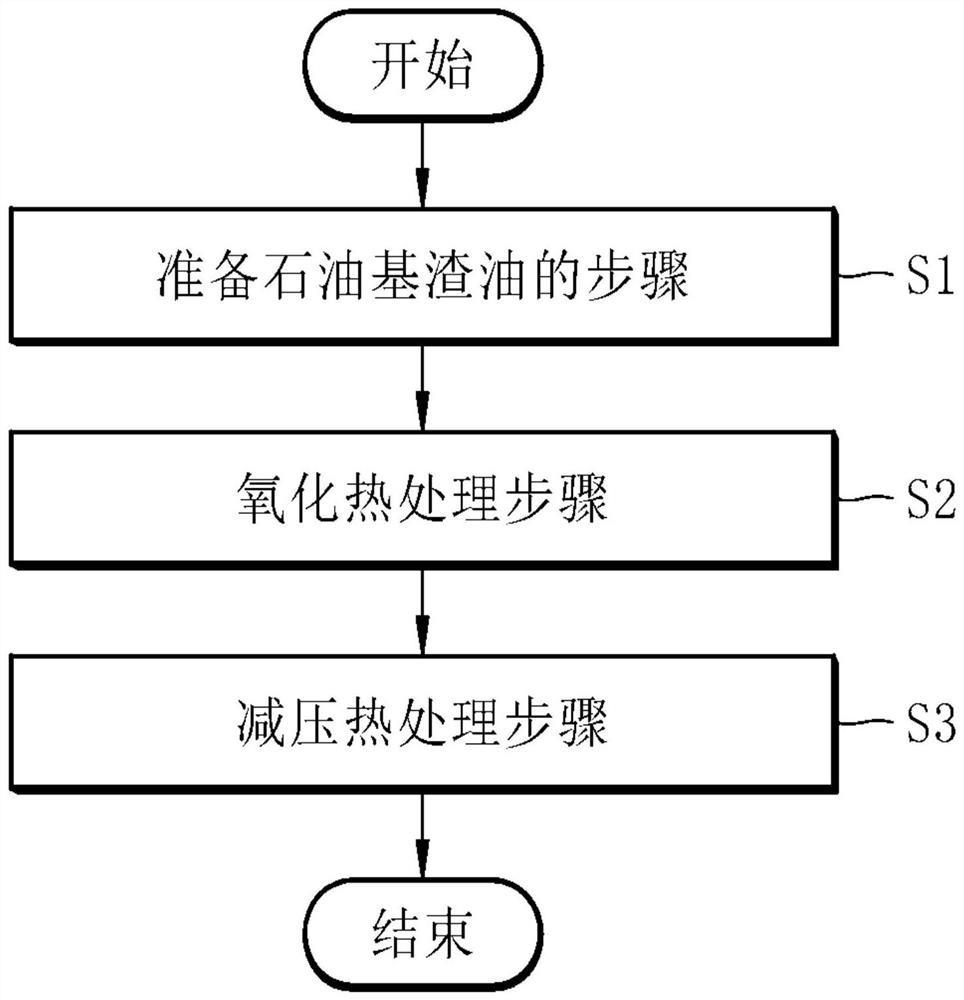

[0017] One embodiment of the present invention provides a method for preparing petroleum-based high softening point asphalt, which is characterized in that it includes: step (a), preparing the content of indene and indene derivatives below 3% by weight by pretreating the petroleum-based residual oil raw material , styrene and styrene derivatives content of 0.3% by weight or less and petroleum-based residual oil with a softening point of 20°C to 150°C (step S1); step (b), mixing oxidizing properties into the above-mentioned petroleum-based residue oxidative heat treatment (step S2) while heating the gas; and step (c), performing decompression heat treatment of heating the product of step (b) under reduced pressure (step S3).

[0018] Firstly, the preparation method of the present invention includes step (a), preparing the indene and indene derivatives content of 3 weight percent or less, and the styrene and styrene derivatives content of 0.3 weight percent or less by pretreating...

Embodiment 1

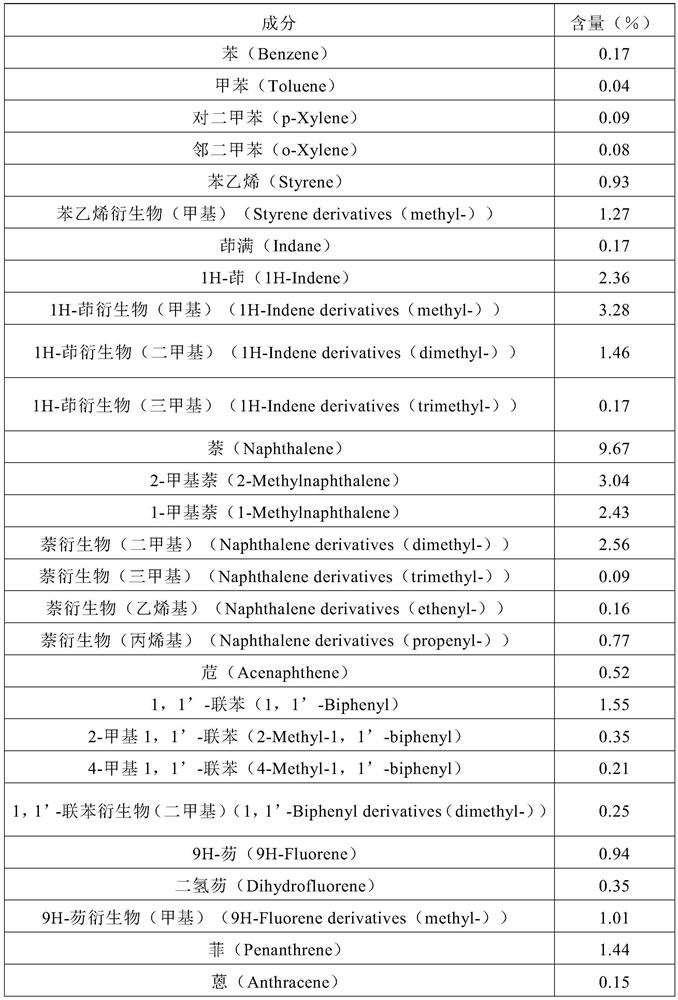

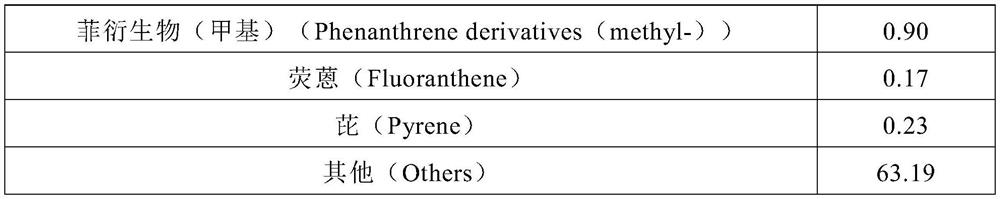

[0053] Using indene, indene derivatives, styrene and pyrolysis fuel oil (PFO) with a content of 9.47% by weight as raw material, petroleum-based residue was prepared by vacuum distillation under the pressure of 150torr and temperature of 200°C . In this case, the softening point of the prepared petroleum-based residue was 38°C, the content of indene and indene derivatives was 1.8% by weight, and the content of styrene and styrene derivatives was 0.12% by weight.

[0054] 800 g of the above-mentioned petroleum-based residue was put into a reactor, and air was injected into the reactor at a flow rate of 0.7 L / min, and oxidation heat treatment was performed at a temperature of 360° C. for 4 hours. Next, the pressure was reduced to a pressure of 100 torr, and a pitch was prepared by performing a heat treatment under reduced pressure at a temperature of 380° C. for 5 hours.

Embodiment 2

[0056] Using the same pyrolysis fuel oil (PFO) as in Example 1 as a raw material, a petroleum-based residue was prepared by atmospheric distillation at a temperature of 320° C. under normal pressure. In this case, the softening point of the prepared petroleum-based residue was 43°C, the content of indene and indene derivatives was 1.4% by weight, and the content of styrene and styrene derivatives was 0.08% by weight.

[0057] 800 g of the above-mentioned petroleum-based residue was put into a reactor, and air was fed into the reactor at a flow rate of 0.5 L / min, and oxidation heat treatment was carried out at a temperature of 370° C. for 4 hours. Next, the pressure was reduced to a pressure of 100 torr, and a pitch was prepared by performing a heat treatment under reduced pressure at a temperature of 380° C. for 5 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com