Special tooling for hoisting high-pressure heaters in thermal power plants and using methods thereof

A technology for high-pressure heaters and thermal power plants, which is applied in transportation and packaging, load suspension components, etc., and can solve the problems of insufficient space for high-pressure heaters in place, limited lifting height of high-pressure heaters, and broken wires of steel wire ropes. and other issues, to achieve the effect of ensuring safety and stability, low cost, and reasonable stress on tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

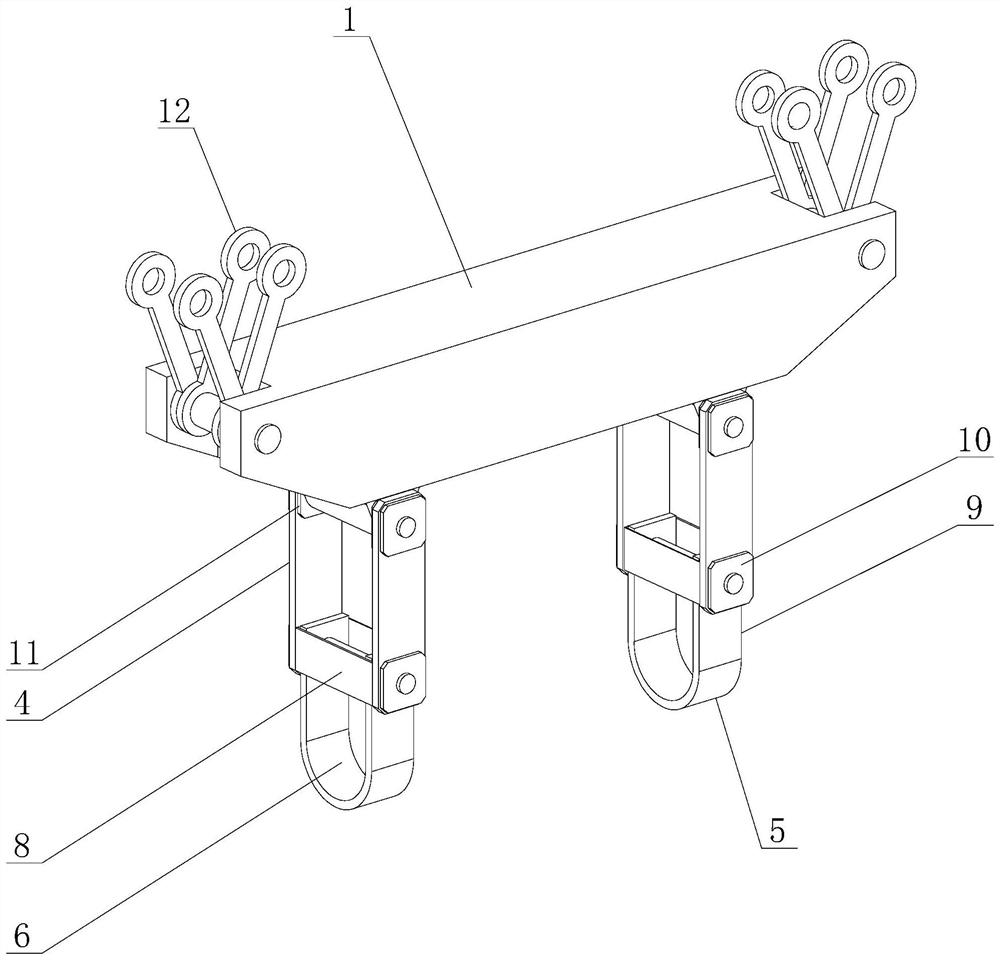

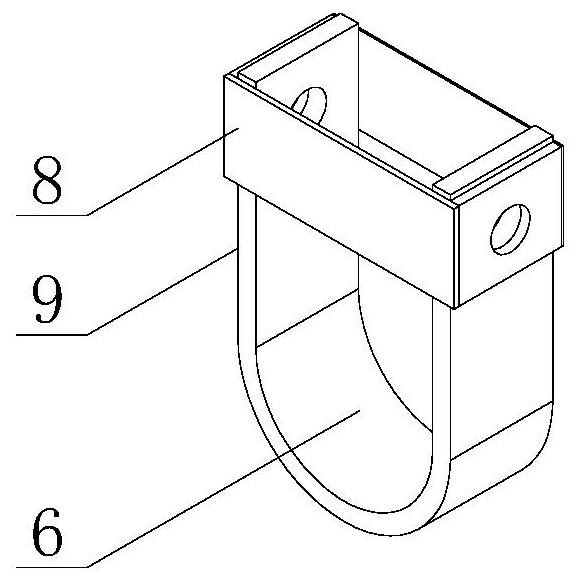

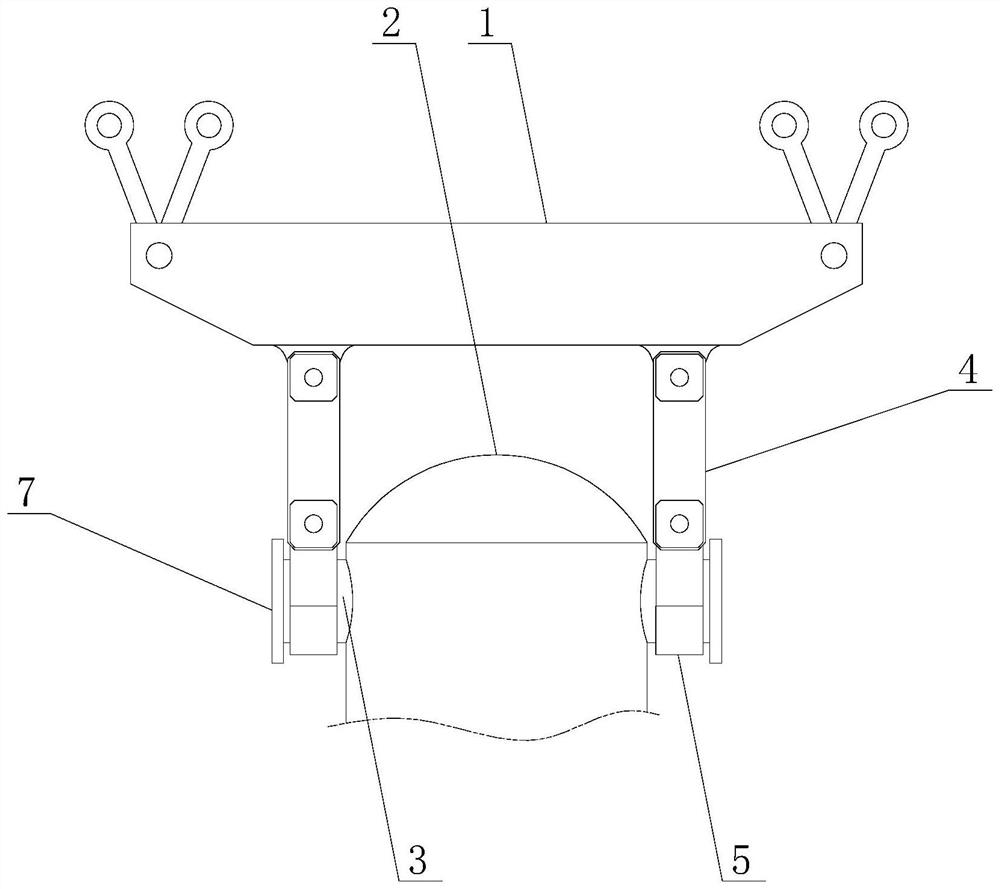

[0033] Example: as attached Figure 1-3 As shown, the present invention is a special tool for hoisting a high-pressure heater in a thermal power plant, including a lifting beam 1, a temporary lifting lug 3 fixed on a high-pressure heater 2, and the number of temporary lifting lugs 3 is four, two Each is a group, and a group of temporary lifting lugs 3 are welded on the outer walls of the upper and lower ends of the high pressure heater 2 . The bottom of the lifting beam 1 is symmetrically provided with two downwardly extending connectors 4, the bottom of the connectors 4 is provided with a hoisting sling 5, and the hoisting sling 5 is provided with a temporary lifting lug 3. Adaptive installation position 6, and the distance between the two lifting slings 5 is adjustable.

[0034] Preferably, the shape of the temporary lifting lug 3 is cylindrical, the bottom surface of the installation position 6 is in a downwardly concave arc shape, and the end of the temporary lifting lu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com