Online sheet turning machine

A technology of flipping and material turning, applied in the field of flipping devices, can solve the problems of complex structure and low turning efficiency, and achieve the effects of high turning efficiency, reduced equipment cost, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

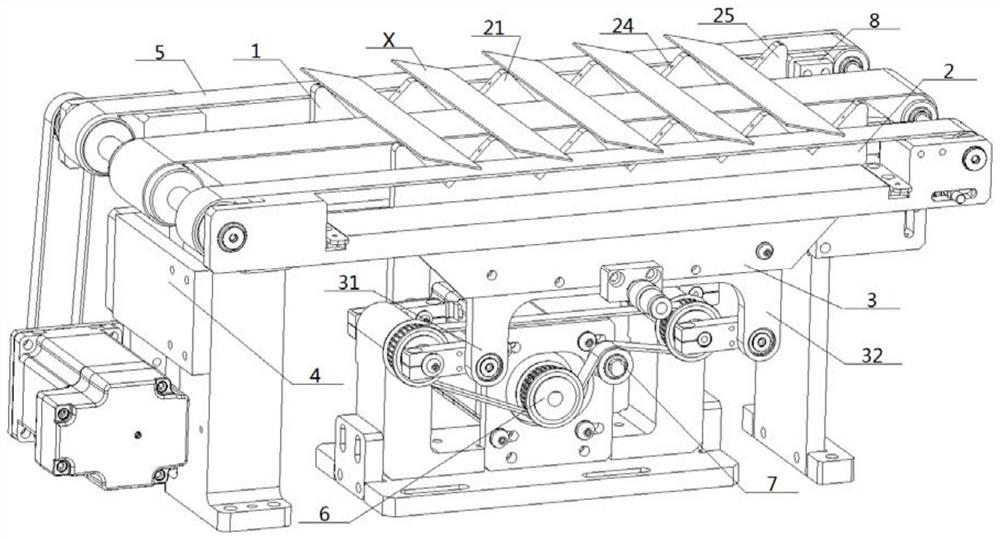

[0064] see figure 1 — Figure 7 , an online film turning machine, including a conveying device and a material turning device, the conveying device conveys a sheet X along the horizontal direction; the conveying device includes at least one conveyor belt 5, and the material turning device includes at least one sheet Stirrer 1;

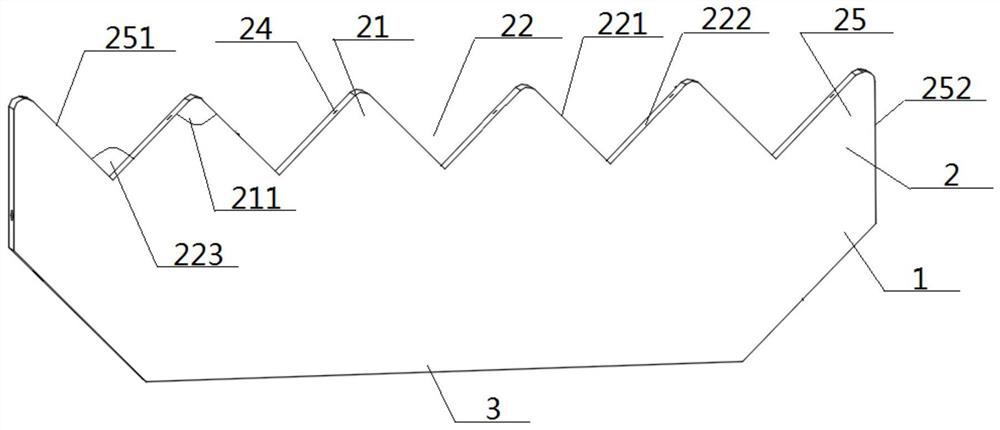

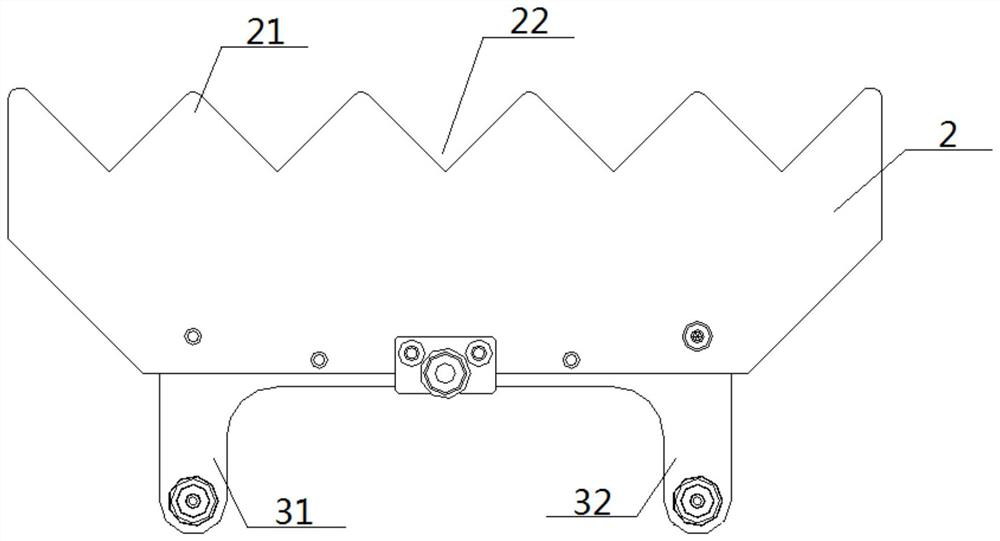

[0065] The top of the sheet material turning rack 1 is provided with a turning part 2, and the turning part 2 includes a plurality of turning teeth 21 connected in sequence, and a turning groove 22 is sandwiched between adjacent turning teeth 21, correspondingly A material turning tooth 21 is sandwiched between adjacent turning troughs 22; said turning trough 22 includes a No. 1 inclined plane 221 and a No. 2 inclined plane 222, and the tops of the No. 1 inclined plane 221 and the No. 2 inclined plane 222 extend upward toward opposite directions. The bottom ends of the No. 1 slope 221 and the No. 2 slope 222 intersect to form a groove angle 223;

[0...

Embodiment 2

[0070] Same as embodiment 1, this implementation also includes a driving device, the driving device is a driving device such as a cylinder, a cam mechanism, the driving end is connected to the bottom of the sheet material turning frame 1, and the sheet material turning frame 1 is driven to go up and down. sports.

Embodiment 3

[0072] The basic content is the same as that of implementation 1, the difference is that: the turning part 2 makes a circular motion, and during the process, the turning part 2 goes up so that the turning groove 21 is not lower than the conveyor belt 5, so that the sheet X is turned into the turning groove 22 and pasted On the No. 1 inclined plane 221 or the No. 2 inclined plane 222, the movement produces an acceleration away from the other inclined plane, so that the sheet X is turned over and attached to the other inclined plane, and the material turning tooth 21 is not higher than the conveyor belt 5 when moving downwards, so that after turning over The sheet X is placed on the conveyor belt 5, see for details Figure 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com