Light aluminum alloy chassis of light rail vehicle body

An aluminum alloy and car body technology, which is applied to the chassis, railway car body components, transportation and packaging, etc., can solve the problems of reduced safety and comfort of light rail, reduced structural strength of the chassis, and increased maintenance workload, etc. Convenience, improved accuracy, reduced assembly effort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

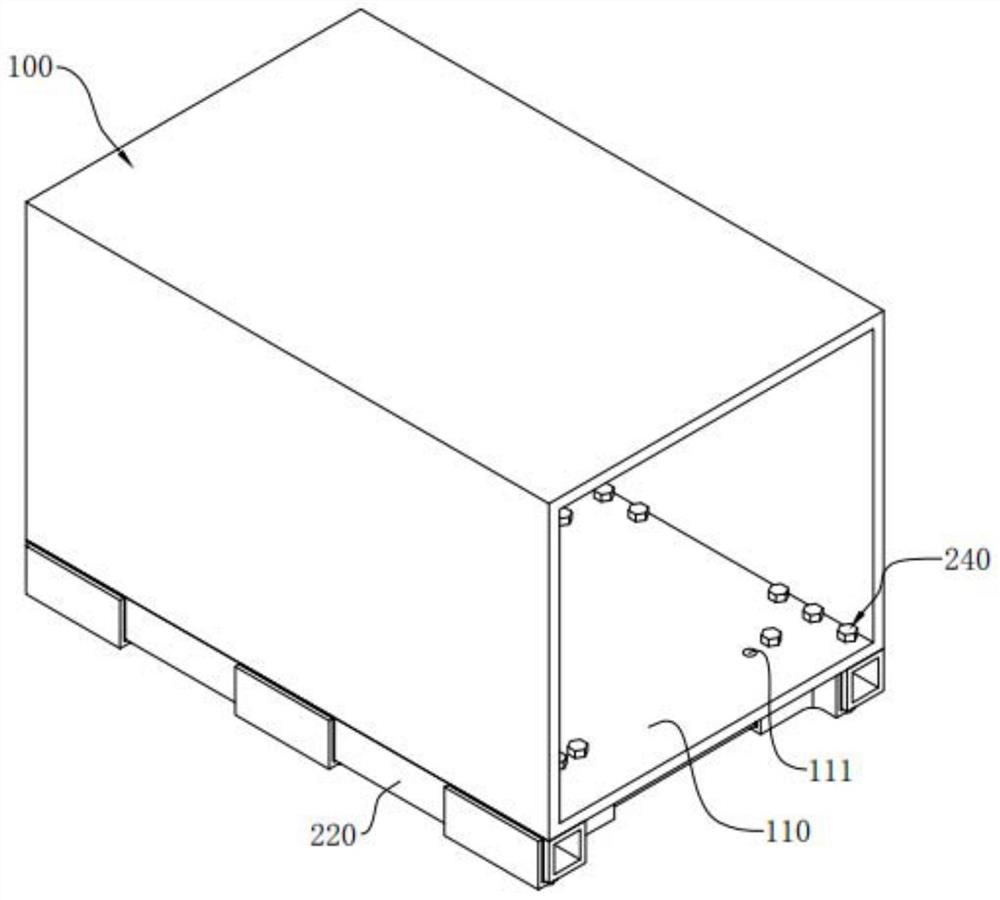

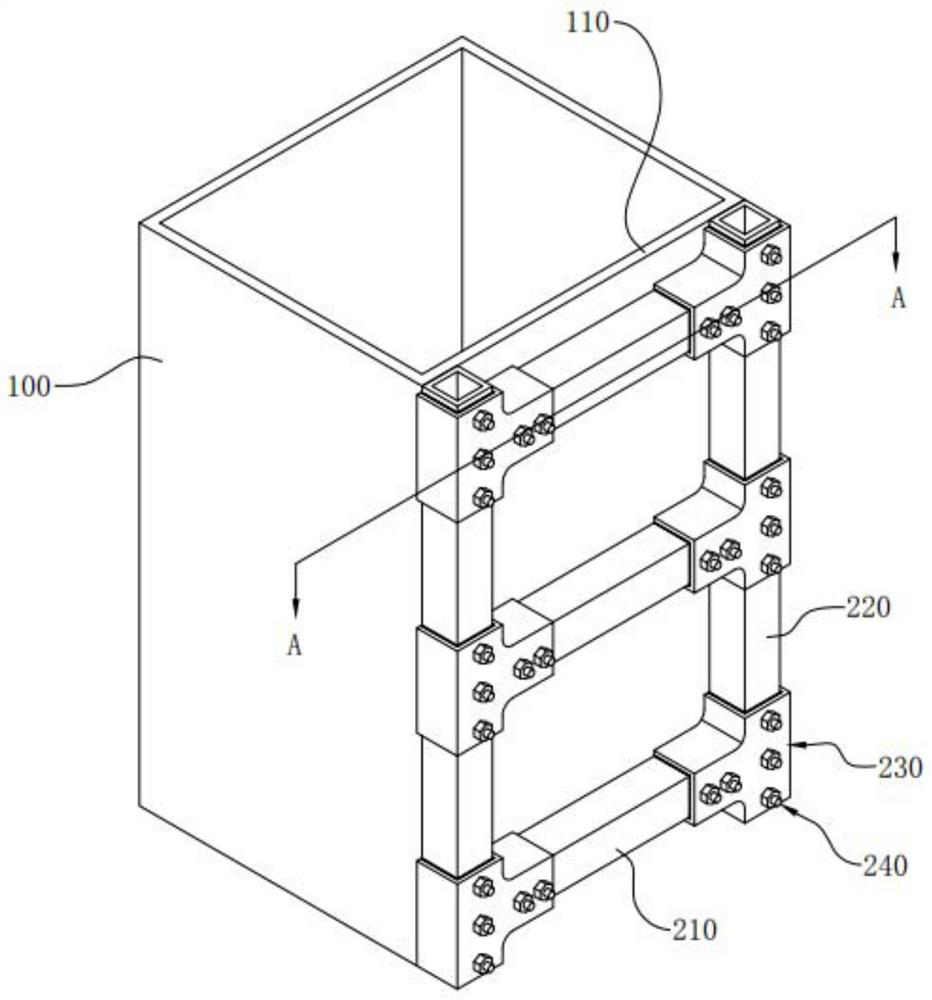

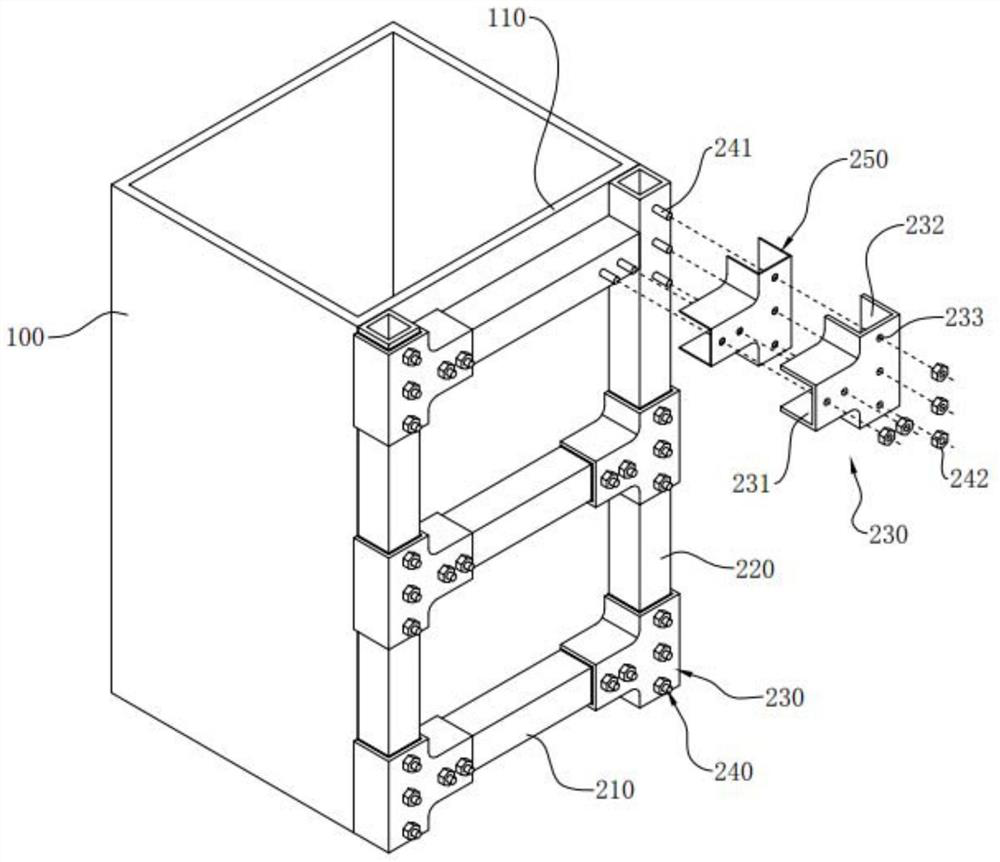

[0038] Please refer to Figure 1 to Figure 3 , in an embodiment of the present invention, a lightweight aluminum alloy underframe for a light rail car body is provided, including a beam 210 and a longitudinal beam 220, and also includes a splicing piece 230 and a fastener 240, and the splicing piece 230 is provided with a transverse card slot 231 and longitudinal slot 232, the longitudinal beam 220 is inserted into the longitudinal slot 232, the end of the beam 210 is inserted into the transverse slot 231, and the splicing piece 230 is fastened to the floor 110 of the vehicle body 100 by the fastener 240 connection, the inner wall of the transverse clamping groove 231 abuts against the outer wall of the beam 210 to restrict the longitudinal movement of the beam 210 and restricts the downward movement of the beam 210, the inner wall of the longitudinal clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com