Material guiding and heating mechanism of plate machining edge bonding machine

A technology for plate processing and heating mechanism, which is applied in wood processing appliances, manufacturing tools, adhesive application devices, etc., can solve the problems of single guiding area, simple structure, limited edge sealing stability and guidance, etc. The effect of improving the edge banding effect, improving the guiding and edge banding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

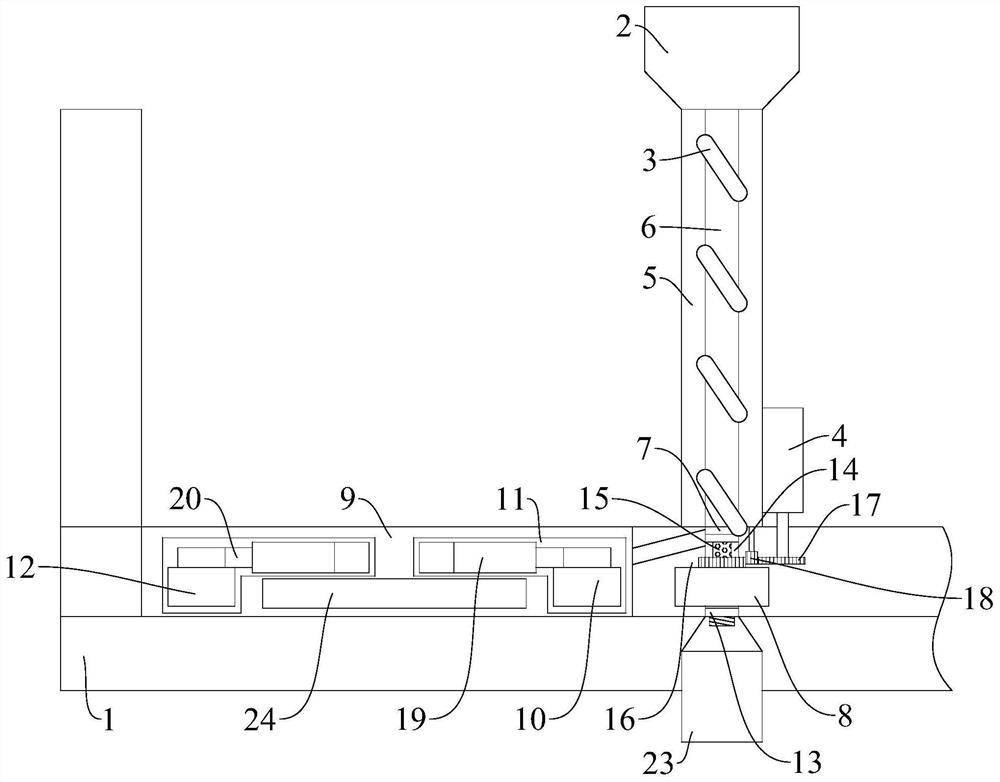

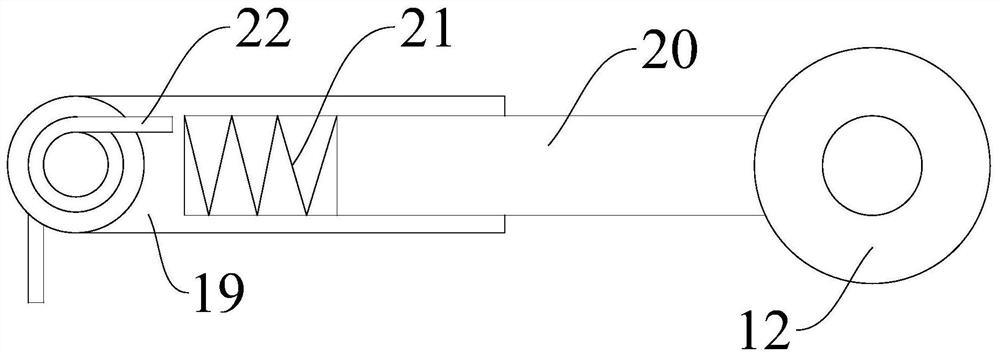

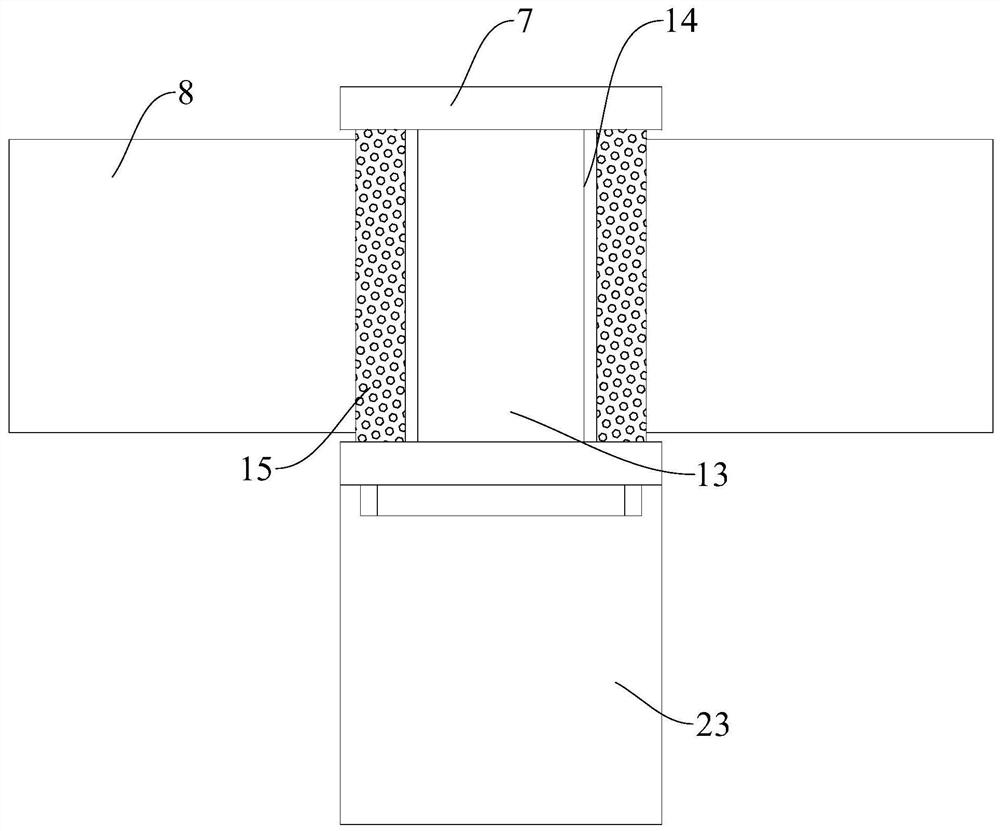

[0019] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0020] figure 1 , figure 2 and image 3 The material guide heating mechanism of a plate processing edge banding machine shown includes a plate guide platform 1 installed on the plate processing edge banding machine, an overhead container 2 with built-in edge banding glue, an electric heating tube 3 and a driving motor 4, and The heating tube 3 and the drive motor 4 are directly purchased from the market, powered by an external power supply, and then controlled on and off by an external switch.

[0021] The upper surface of the plate guide platform 1 is located on the outer edge and is fixed with a lateral fixed frame 5 for fixing and installing the overhea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com