Badminton head hole-pressing device used for badminton making

A badminton and ball-using technology, applied in climate change adaptation, metal processing, etc., can solve the problems of low work efficiency, hand soreness affecting follow-up work, laborious and other problems, and achieve the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

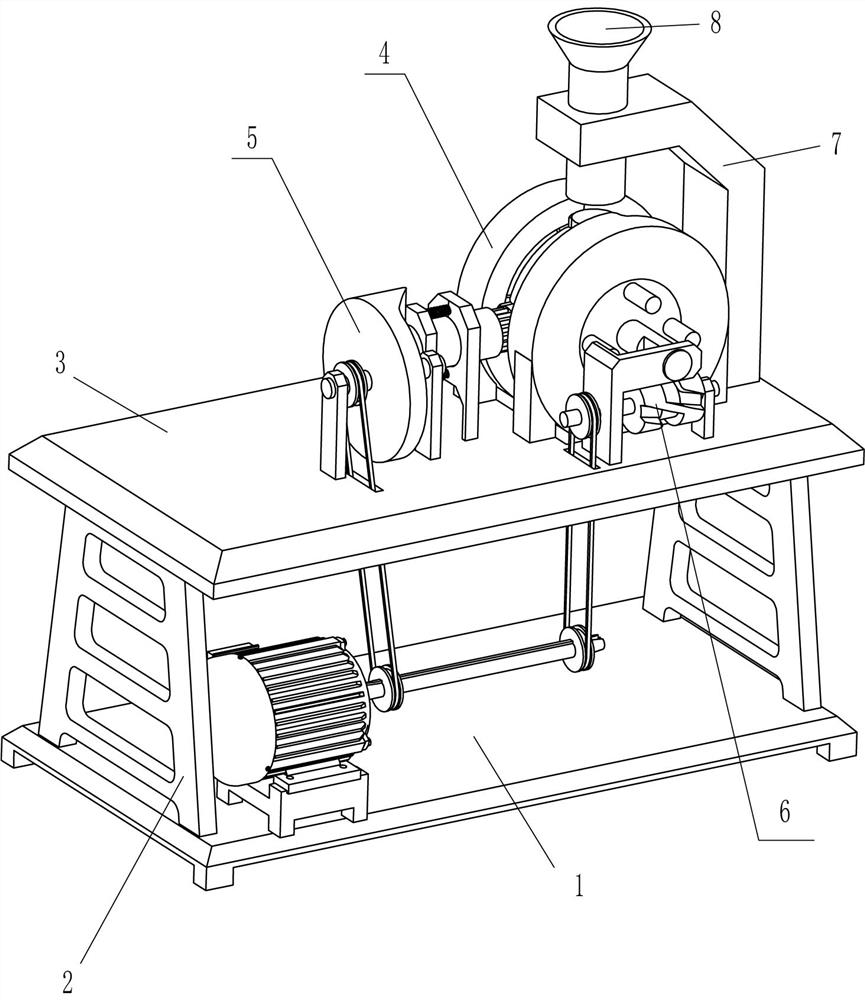

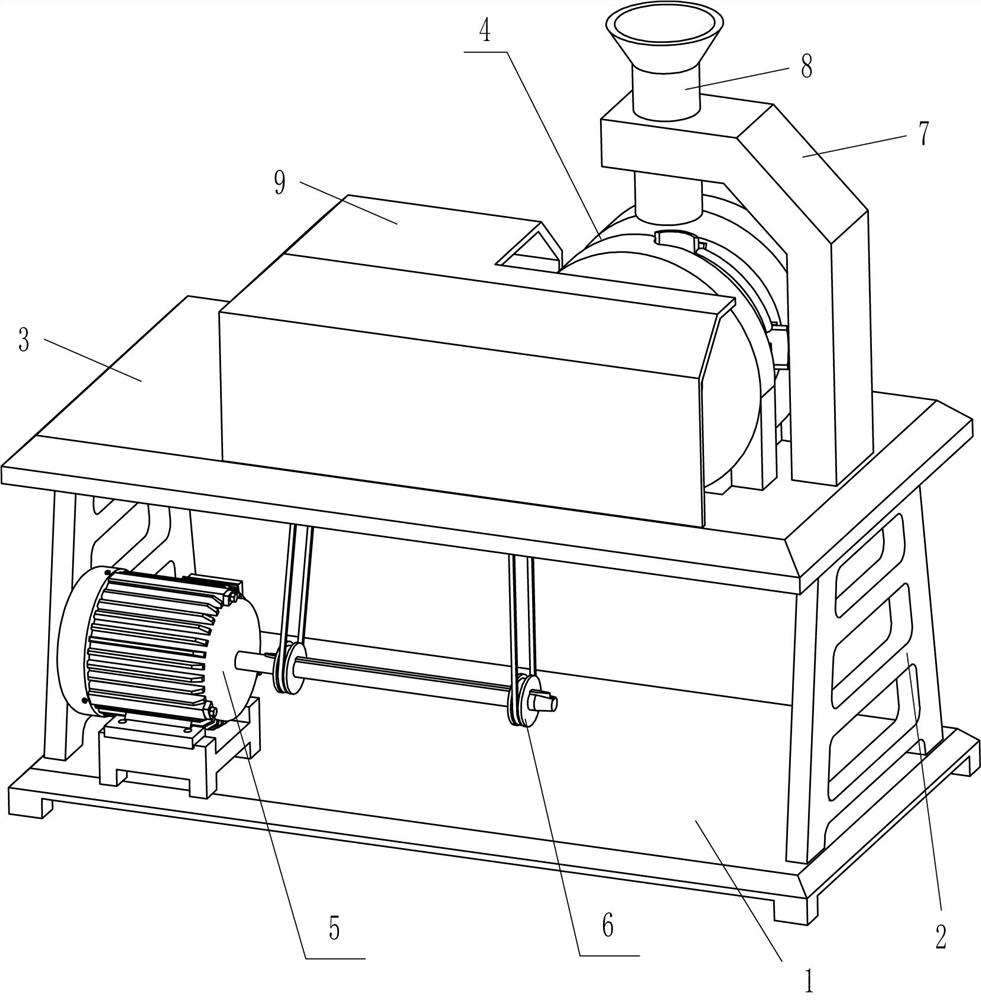

[0024] A ball head pressing hole device for making badminton, such as Figure 1-Figure 4 As shown, it includes a base 1, a stand 2, a horizontal plate 3, a feeding device 4 and a pressing device 5, the left and right sides of the top of the base 1 are fixedly connected with the stand 2, and the top of the stand 2 on the left and right sides is fixed. A horizontal plate 3 is connected, an opening is opened in the middle of the right part of the horizontal plate 3, a feeding device 4 is provided on the right side of the top of the horizontal plate 3, a pressing device 5 is arranged between the left part of the horizontal plate 3 and the left side of the top of the base 1, and The feeding device 5 cooperates with the feeding device 4.

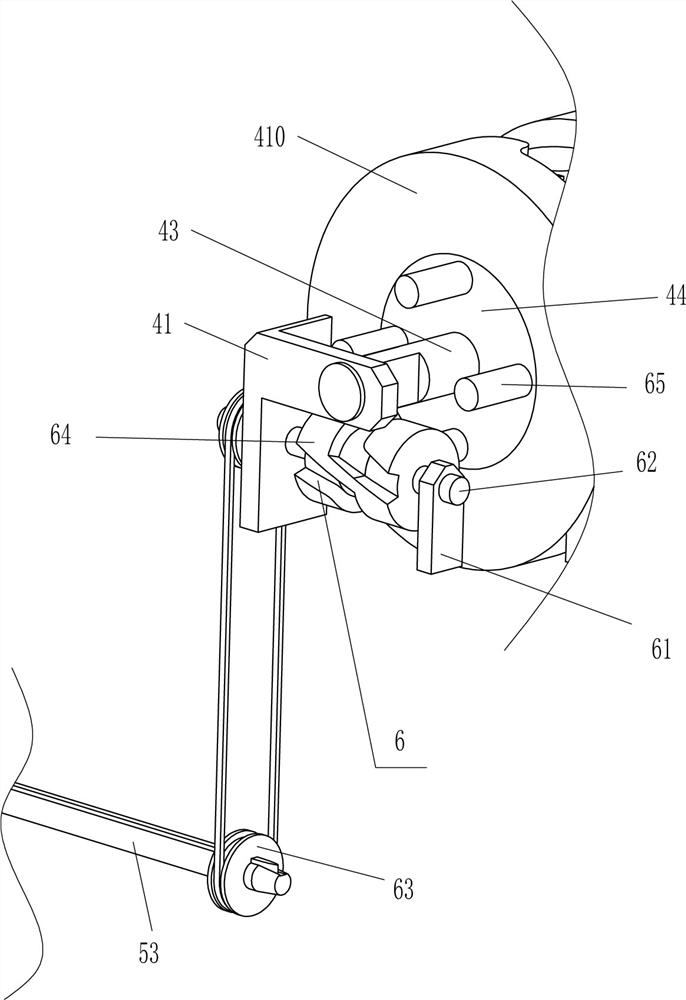

[0025] The conveying device 4 includes a special-shaped frame 41, a first vertical plate 42, a first rotating shaft 43, a rotating cylinder 44, a limit ring 45, a second rotating shaft 46, a clamp block 47, a swash plate 48, a first spring 49 and ...

Embodiment 2

[0031] On the basis of Example 1, such as figure 1 , figure 2 and Figure 5 As shown, a driving device 6 is also included, and the driving device 6 includes a third vertical plate 61, a fifth rotating shaft 62, a second transmission assembly 63, a groove drum 64 and a contact rod 65, and the front part of the top right side of the horizontal plate 3 is fixed There is a third vertical plate 61, and a fifth rotating shaft 62 is rotatably connected between the upper part of the third vertical plate 61 and the lower part of the special-shaped frame 41. The right part of the fifth rotating shaft 62 is circumferentially fixed with a groove tube 64. The fifth rotating shaft 62 A second transmission assembly 63 is connected between the left circumference and the right circumference of the third rotating shaft 53, the second transmission assembly 63 runs through the horizontal plate 3, and four contact rods 65 are fixedly fixed on the front side of the rotating cylinder 44 at even in...

Embodiment 3

[0034] On the basis of embodiment 1 and embodiment 2, such as figure 1 As shown, it also includes an L-shaped frame 7 and a blanking tube 8, the middle of the right side of the top of the horizontal plate 3 is fixedly connected with an L-shaped frame 7, and the middle of the left part of the L-shaped frame 7 is fixedly connected with a blanking tube 8. 8 is located directly above the limit ring 45.

[0035] It also includes a protective case 9, the top front side of the horizontal plate 3 is fixedly connected with the protective case 9, the swash plate 57 and the puncher 59 are located in the protective case 9, and the groove tube 64 is also located in the protective case 9.

[0036] Firstly, the operator drops a ball head into the feeding pipe 8, and the ball head in the feeding pipe 8 falls between the two clamping blocks 47 above. In this way, the ball head can be accurately dropped between the two clamping blocks 47 above.

[0037] When the device is in operation, the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com