Steering wheel assembly automatic assembling processing line and assembling process

A steering wheel and processing line technology, applied in metal processing equipment, assembly machines, manufacturing tools, etc., can solve the problems that the steering wheel assembly cannot be assembled automatically, and achieve the effects of low assembly efficiency, precise positioning and coordination, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

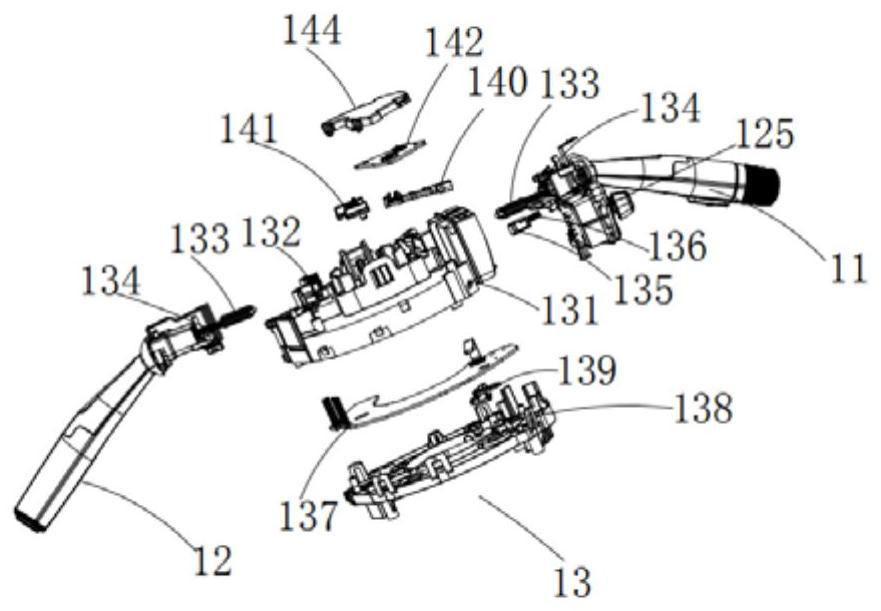

[0072] like Figure 1 to Figure 51 As shown, a steering wheel assembly automatic assembly processing line is used to assemble a steering wheel assembly 1. The steering wheel assembly 1 is formed by assembling a left handle unit 11, a right hand unit 12 and a steering wheel body unit 13. The steering wheel body unit 13 is assembled and formed. It consists of base 131, stop shifter 132, piston a133, spring a134, piston b135, spring b136, PCB main board 137, bracket cover 138, pawl 139, rotating carrier 140, contact module 141, handle PCB board 142 , PCB board shield 143, spring bracket 144, spring sheet 145, bearing 146, front shield 147, clock unit 148, gear box 149 and rear shield 150 are assembled and formed for assembling the automatic steering wheel assembly 1 The assembly processing line includes, in order of assembly:

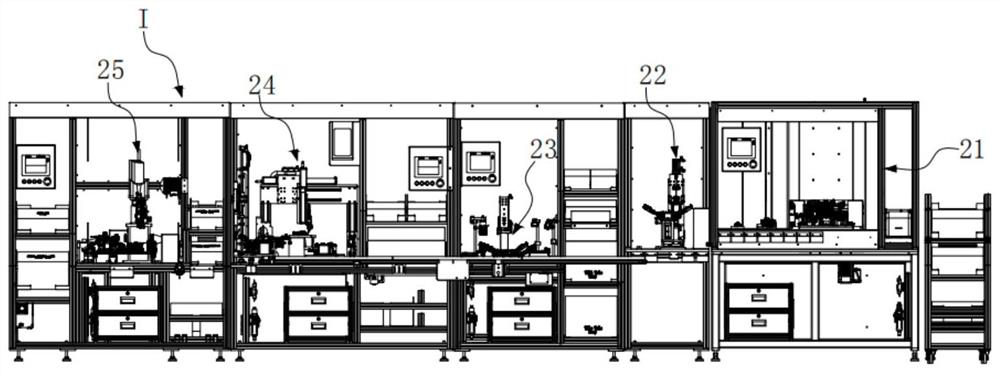

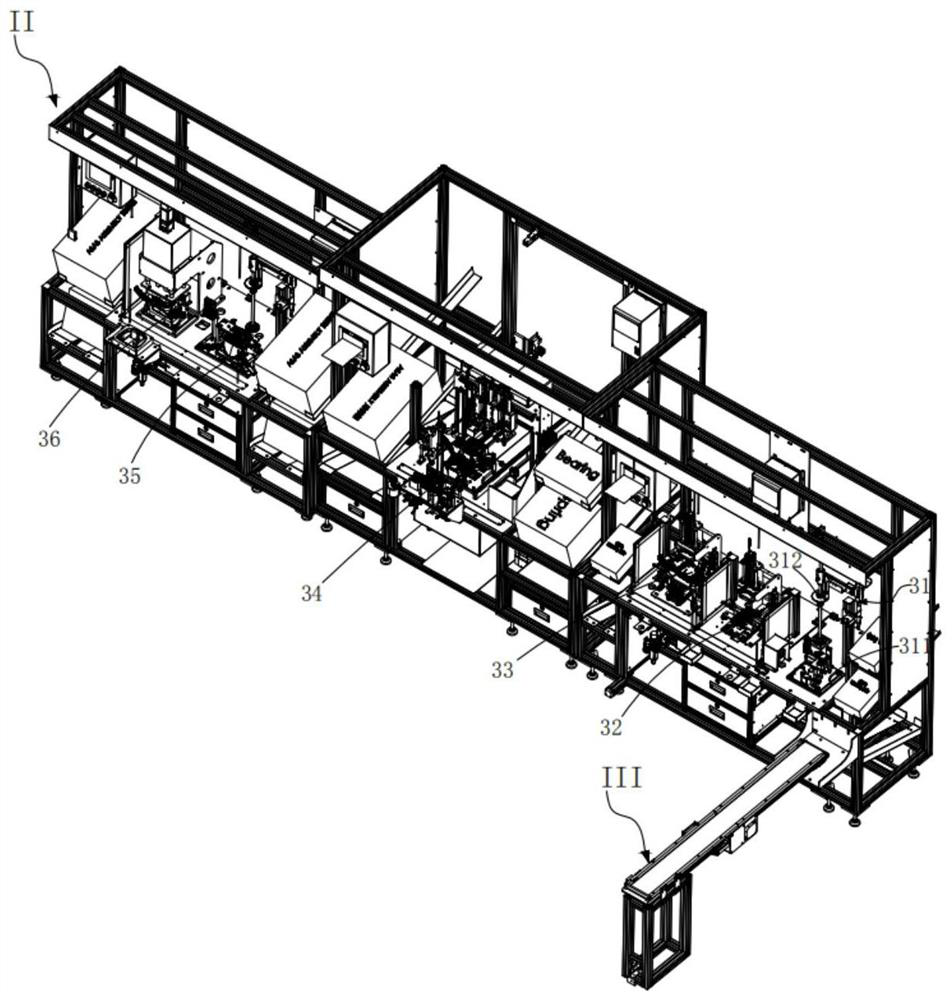

[0073] The front assembly processing station 1 includes a turntable pre-assembly mechanism 21, a handle assembly mechanism 22, a main board pressing mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com