Buffer double-head cap screwing device

A double-head, outer cover technology, applied in the field of machinery, can solve the problems of low assembly efficiency, screwed workpieces, skewed inner and outer threads, etc., to improve work efficiency and assembly accuracy, and solve the effect of low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

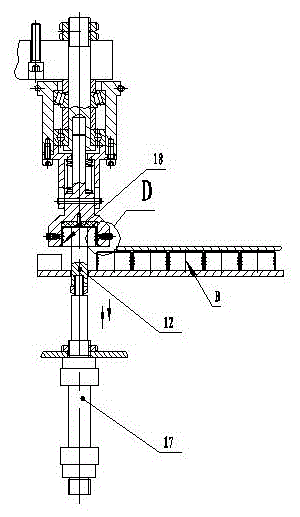

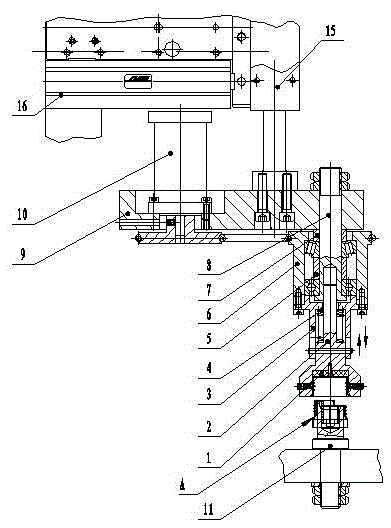

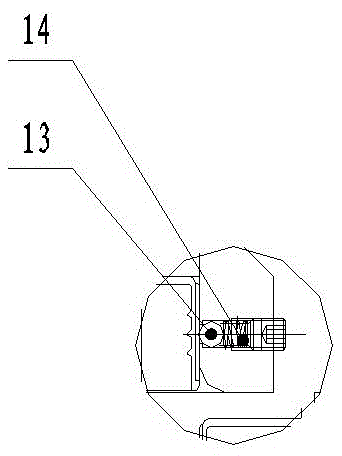

[0011] For better understanding and implementation, the present invention will be further described below in conjunction with the accompanying drawings: buffer type double-ended cap screwing device, including outer cover jacking device, mold 11 for placing silk sleeve, screw cap device, screw cap device includes fixing Plate 9, fixed plate 9 links to each other with horizontal movement cylinder 16 through DC brushless motor 10, and horizontal movement cylinder 16 side is provided with vertical movement cylinder 15, and fixed plate 9 is provided with connecting rod 8, and connecting rod 8 is provided with, and Set Ⅱ7, spacer Ⅰ5 and bearing sleeve 6, bearings are arranged between spacer Ⅱ7, spacer Ⅰ5 and bearing sleeve 6, the lower part of the connecting rod 8 is provided with a pressure rod 2, and the outside of the pressure rod 2 is provided with a connecting sleeve 3, the connecting sleeve 3 and the bearing sleeve 6 are fixedly connected by screws, the pressure rod 2 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com