Acoustic vortex ultrasonic cleaning device

A technology of ultrasonic cleaning and vortex, which is applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., and can solve problems such as limited fluid flow speed and unfavorable peeling of dirt layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

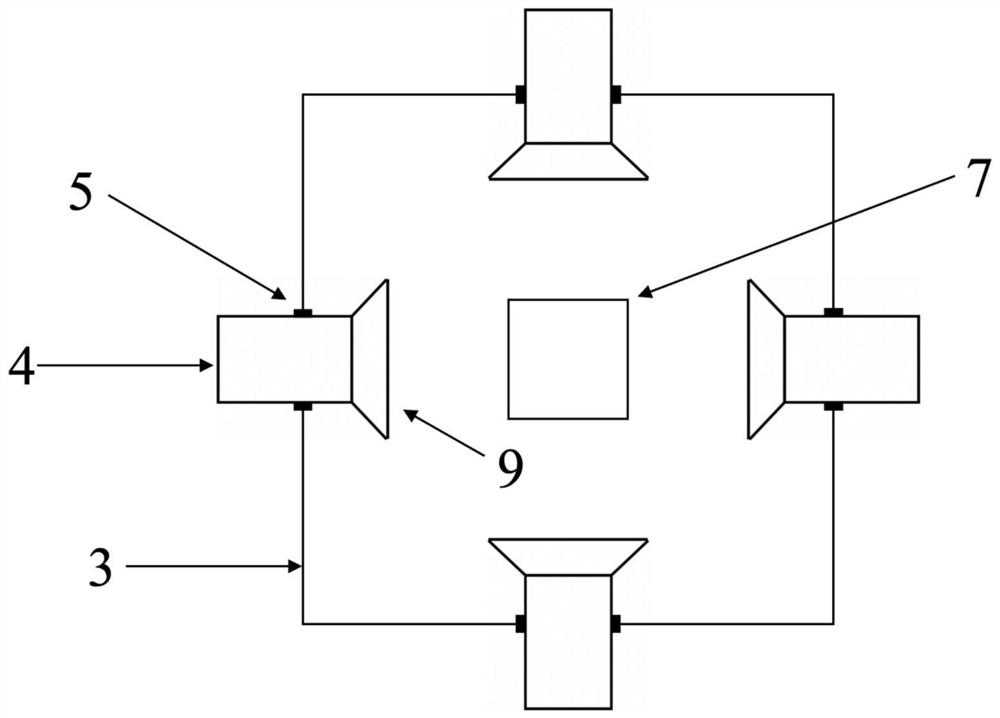

[0022] figure 1 It is a structural schematic diagram of the device of the present invention, including an ultrasonic signal generation and control system 1, a power amplification system 2, a cleaning tank 3, an electroacoustic transducer 4, a sealing coil 5, a lifting bracket 6, a cleaning object placement platform 7, and a cleaning tank cover 8 , an ultrasonic transmitting terminal 9 , and a glove operation interface 10 . In this embodiment, the cleaning tank 3 has a cubic structure, and the center of the side wall has an interface matching the structure of the electro-acoustic transducer 4 and is sealed by the sealing coil 5. The bottom center of the cleaning tank 3 is provided with a liftable support 6, The upper end is connected to the cleaning object placement platform 7, and the cleaning tank cover 8 is arranged on the top of the cleaning tank 3 and can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com