Method for preparing solvent-resistant and acid-alkali-resistant homoporous membrane through crosslinking

A technology of acid and alkali resistance and solvent resistance, which is applied in the field of cross-linking preparation of homoporous membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

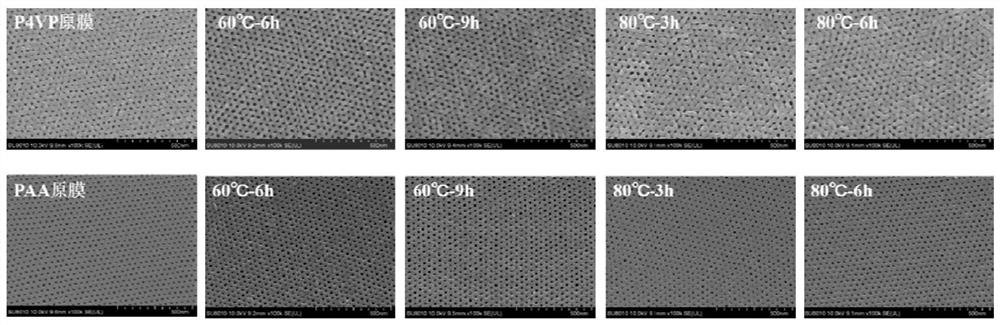

[0032] (1) Preparation of homoporous membrane: the PS-b-P4VP block copolymer with a molecular weight of 210,000g / mol, wherein PS accounts for 71wt%, is dissolved in N, N dimethylformamide / 1,4 dioxane / tetrahydrofuran = 4:3:3 mixed solvent, stir until uniformly dissolved, after standing for a period of time, apply it to a clean glass plate with a scraper with a thickness of 150 μm, volatilize for 15 seconds, and then immerse in water Phase inversion to form a film. After the solvent exchange is complete, the formed film is taken out and dried to obtain a homoporous film. The electron microscope characterizes its structure, see attached figure 1 The original membrane picture in the upper left corner of .

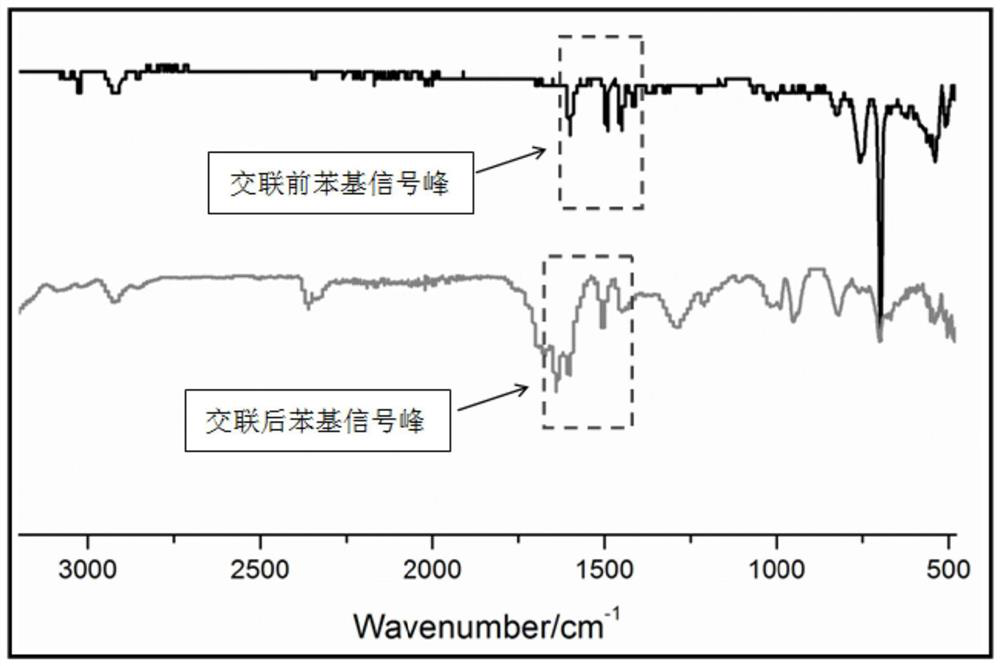

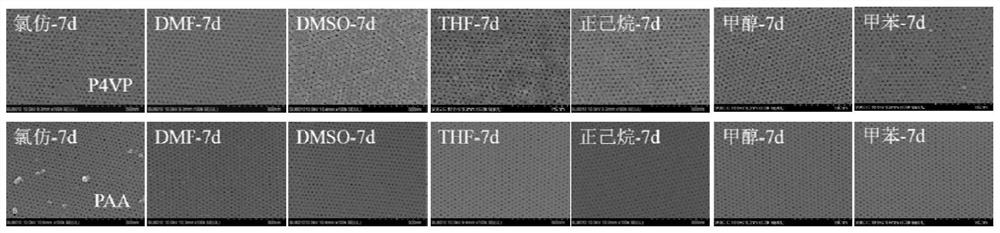

[0033] (2) Cross-linking reaction and post-treatment: immerse the film prepared above into a 0.5 g / ml ferric chloride / formaldehyde dimethyl acetal cross-linking agent solution, heat and react at 60°C for 6 hours, take out the film after reaction, and use Rinse 3 times with et...

Embodiment 2

[0040](1) Preparation of homoporous membrane: PS-b-P4VP block copolymer with a molecular weight of 100,000g / mol, in which PS accounts for 75wt%, is dissolved in 1,4 dioxane / tetrahydrofuran at a concentration of 25wt% / dimethylformamide = 4.9:2.1:3 mixed solvent, stir until uniformly dissolved, after standing for a period of time, use a scraper with a thickness of 150 μm to coat a clean glass plate, volatilize for 90 seconds, and then immerse in water for phase transformation into Membrane, after the solvent exchange is complete, the formed film is taken out and dried to obtain a homoporous membrane, and the homoporous structure on the surface is characterized by electron microscopy.

[0041] (2) Cross-linking reaction and post-treatment: immerse the film prepared above into a 0.25 g / mol aluminum trichloride / formaldehyde dimethyl acetal cross-linking agent solution, react at 20°C for 12 hours, take out the film after reaction, Rinse three times with ethanol, rinse once with ac...

Embodiment 3

[0046] (1) Preparation of homoporous membrane: PS-b-PAA block copolymer with a molecular weight of 150,000g / mol, in which PS accounts for 84wt%, is dissolved in 1,4-dioxane at a concentration of 22wt% , stir until it dissolves evenly, after standing for a period of time, use a scraper with a thickness of 150 μm to coat it on a clean glass plate, immerse in water after volatilization for 10 seconds to form a phase conversion film, and after the solvent exchange is complete, take out the formed film and dry it to obtain Homoporous film, electron microscope characterizes its homogeneous surface structure, see figure 1 The first picture of the second row.

[0047] (2) Cross-linking reaction and post-treatment: immerse the film prepared above into a 5g / ml ferric chloride / dimethyl acetal cross-linking agent solution, heat and react at 80°C for 6h, and wash the film after reaction with ethanol for 3 times , washed with acetic acid for 3 times, then transferred to dimethyl sulfoxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com