Pulp extracting device for tomato sauce production

An extraction device and a technology for tomato paste, applied in the agricultural field, can solve the problems of poor removal effect, affect the taste and quality of tomato paste, etc., and achieve the effects of easy cleaning, improved convenience, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

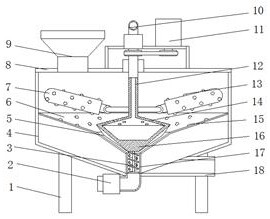

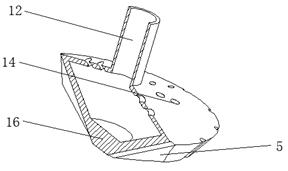

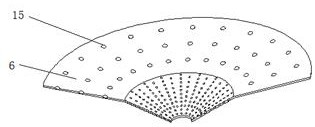

Embodiment 1

[0027] refer to Figure 1-4 , a pulp extraction device for tomato paste production, comprising a frame 1, a tank body 4 is fixedly installed on the top of the frame 1, and an end cover 8 is fixedly installed on the top of the tank body 4, and an inlet is fixedly installed on the top of the end cover 8 The top of the hopper 9 and the end cover 8 is equipped with a pipe body 12 through a bearing, and the bottom end of the pipe body 12 is fixedly equipped with a grinding roller 16 with a tapered structure at the bottom, and the top end of the end cover 8 is fixedly installed with a The drive mechanism 11 connected with the body 12, the inside of the tank body 4 is fixedly equipped with a separation net cover 6, and the bottom end of the separation net cover 6 is fixedly installed with an L-shaped slag discharge pipe 17, and the bottom end of the separation net cover 6 is set There is a separation net pocket part matched with the grinding roller 16, and the bottom end of the separ...

Embodiment 2

[0036] refer to Figure 1-5 , a kind of pulp extraction device for tomato paste production. Compared with Embodiment 1, the outer top of the slag discharge pipe 17 is provided with a plurality of discharge holes, and the bottom end of the rolling roller mechanism 7 is fixedly installed with a spiral Distributed pushing paddles 3, the pushing paddles 3 are located inside the vertical section of the slag discharge pipe 17, when the device extracts the pulp, residues such as peels and seeds slowly collect in the slag discharge pipe 17, and push The paddle 3 can push it to the slag discharge valve 2. During the pushing process, the residue is squeezed to squeeze out the pulp contained inside from the discharge hole, so as to avoid the waste of pulp and reduce the production cost of tomato paste.

[0037] When this embodiment is in use, when the device is extracting pulp, residues such as peels and seeds are slowly collected in the residue discharge pipe 17, and the pushing paddle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com