Full-automatic fresh tea leaf ventilating storage device

A fully automatic, tea-leafing technology, applied in tea processing before extraction, etc., can solve problems such as difficulty in adequate ventilation and drying, and achieve the effect of drying and heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

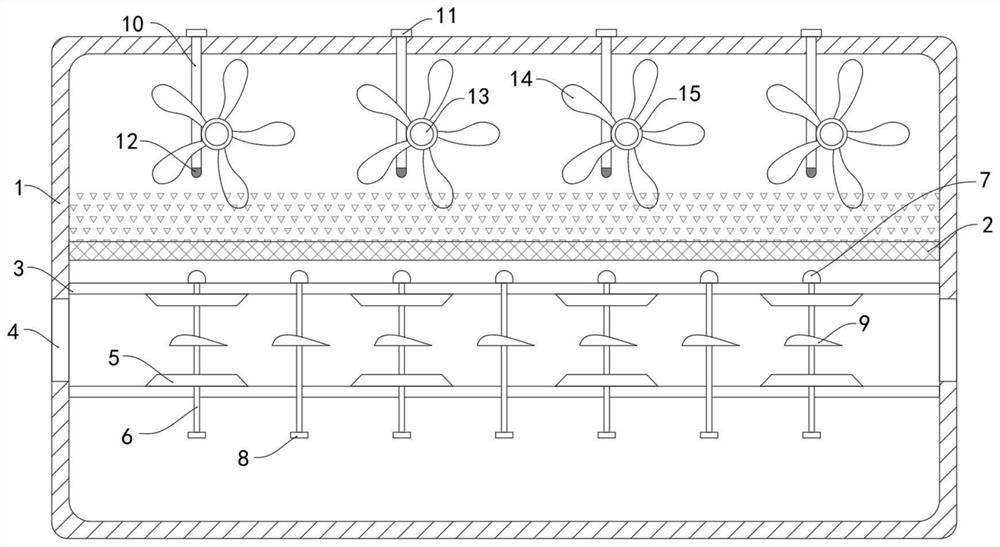

[0021]Such asfigure 1 As shown, a fully automatic green tea storage device includes a fixed frame 1, in which a horizontally arranged elastic net 2 is fixedly connected to the fixed frame 1, and the tea leaves are laid flat on the elastic net 2 during the working process. The density of the tea water vapor If it is larger than air, it will move below the elastic net 2, and the air flow will flow from the lower end of the elastic net 2, which can fully take away the moisture of the tea leaves and play a better drying effect.

[0022]There are two fixed plates 3 arranged horizontally under the elastic net 2, and the side walls of the fixed frame 1 between the two fixed plates 3 are provided with ventilation holes 4, and the two fixed plates 3 are fixed on the opposite side walls. A plurality of evenly arranged fixing blocks 5 are connected, and the plurality of fixing blocks 5 on the two fixing plates 3 are arranged one by one, a narrow air passage is formed between the two fixing blocks...

Embodiment 2

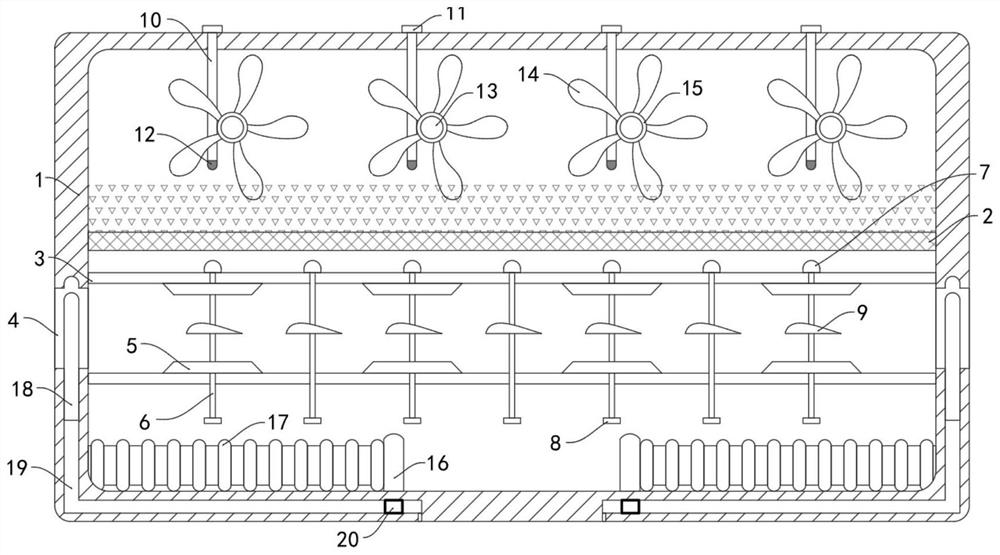

[0033]Such asfigure 2As shown, the difference between this embodiment and embodiment 1 is that: the inner bottom surface of the fixed frame 1 is slidably connected with two magnetic sliding plates 16, and the two magnetic sliding plates 16 and the side walls of the fixed frame 1 are fixedly connected with internal The elastic bellows 17 containing the evaporating liquid, the two vent holes 4 are slidably connected with a closing plate 18, the side wall of the fixing groove 1 is provided with an air passage 19 matching the closing plate 18, and the other end of the air passage 19 slides A magnetic sliding block 20 that attracts opposite poles of the magnetic sliding plate 16 is connected.

[0034]In this embodiment, when the temperature in the fixed frame 1 is too high to the boiling point of the evaporating liquid, the evaporating liquid will vaporize in the elastic bellows 17. The elastic bellows 17 pushes the magnetic sliding plate 16 to move, and the magnetic sliding plate 16 moves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com