Vacuum-printing conductive paste

A conductivity and vacuum technology, applied in the direction of conductive materials, conductive materials, printed circuit components, etc., can solve the problems of slurry viscosity increase, printing performance reduction, solvent volatilization, etc., to maintain printing performance and excellent adhesion , The effect of suppressing the increase in viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

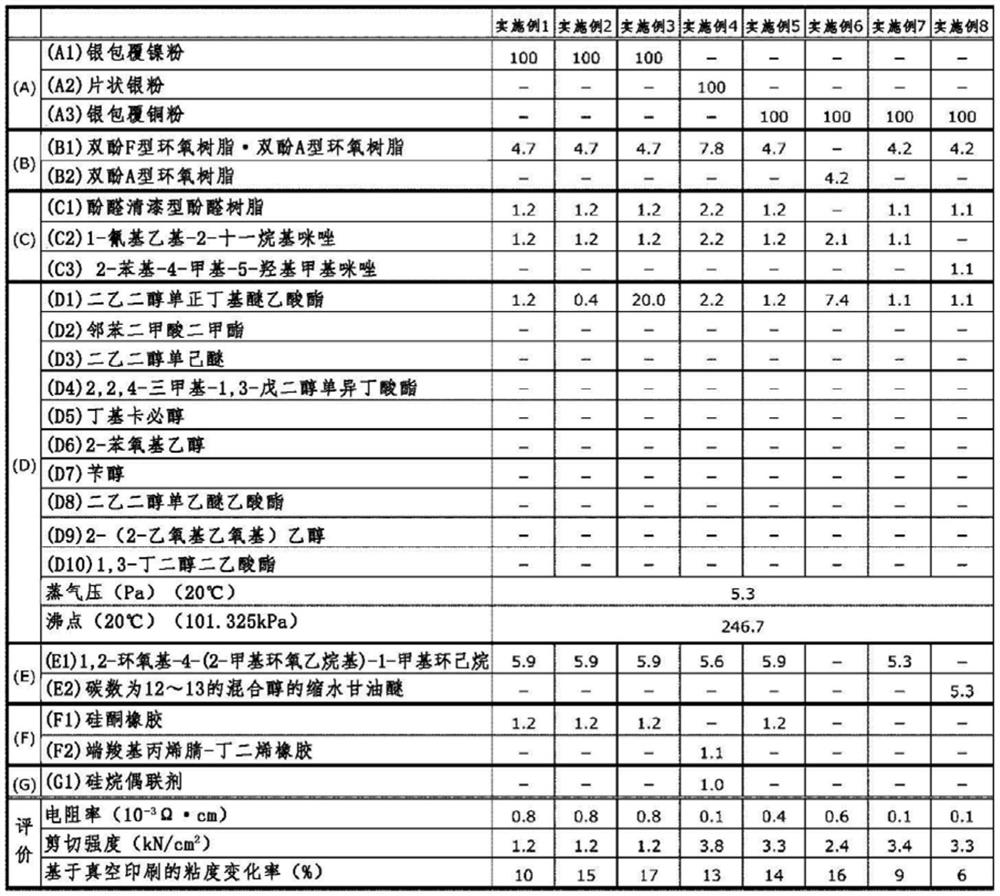

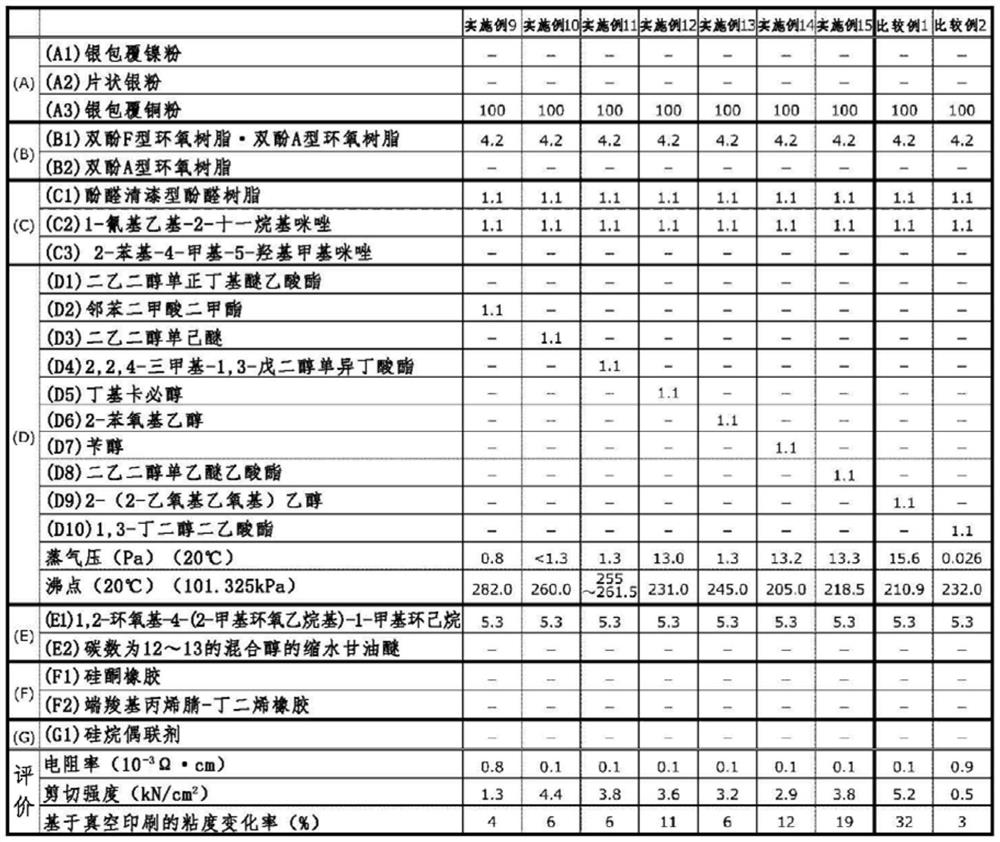

Embodiment 1~15 and comparative example 1~2

[0082] The electroconductive paste for vacuum printing was manufactured by mixing and dispersing each raw material using a three-roll mill so that it might become the compounding ratio shown in following Table 1 and Table 2. The numerical values related to each composition in Table 1 and Table 2 represent parts by mass. The raw materials (each component) used at the time of preparation of the said electroconductive paste are as follows.

[0083] (A) Conductive filler

[0084] (A1) Silver-coated nickel powder (manufactured by NEMIS Corporation, volume average particle diameter D50: 5 μm). The quantity of silver was 10 mass parts with respect to the total of 100 mass parts of silver and nickel powder (purity of nickel: 99.9 mass %) about this silver-coated nickel powder. This silver-coated nickel powder is manufactured by the manufacturing method described in Japanese Patent No. 5764294.

[0085] (A2) Flake silver powder (trade name: FA2, manufactured by DOWA ELECTRONICS Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com