Disc type motor rotor magnetic steel assembling tool and assembling method thereof

A disc motor and assembly tooling technology, which is applied in the direction of motors, electromechanical devices, and motor generators, can solve the problems of low assembly efficiency, mutual attraction of magnets, and unfavorable safe operation, and achieve the effect of accurate assembly position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

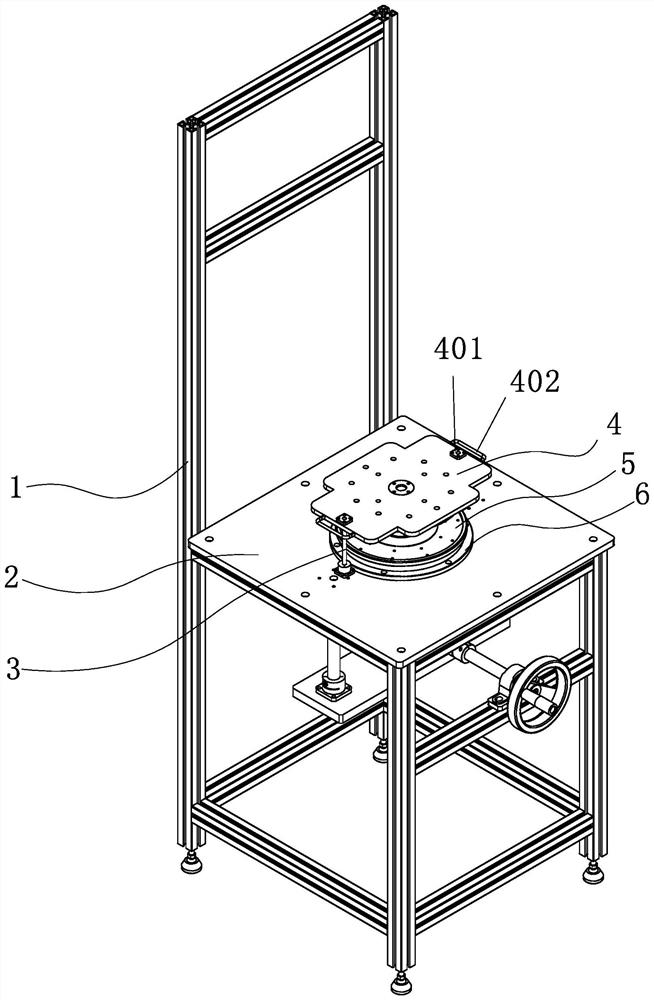

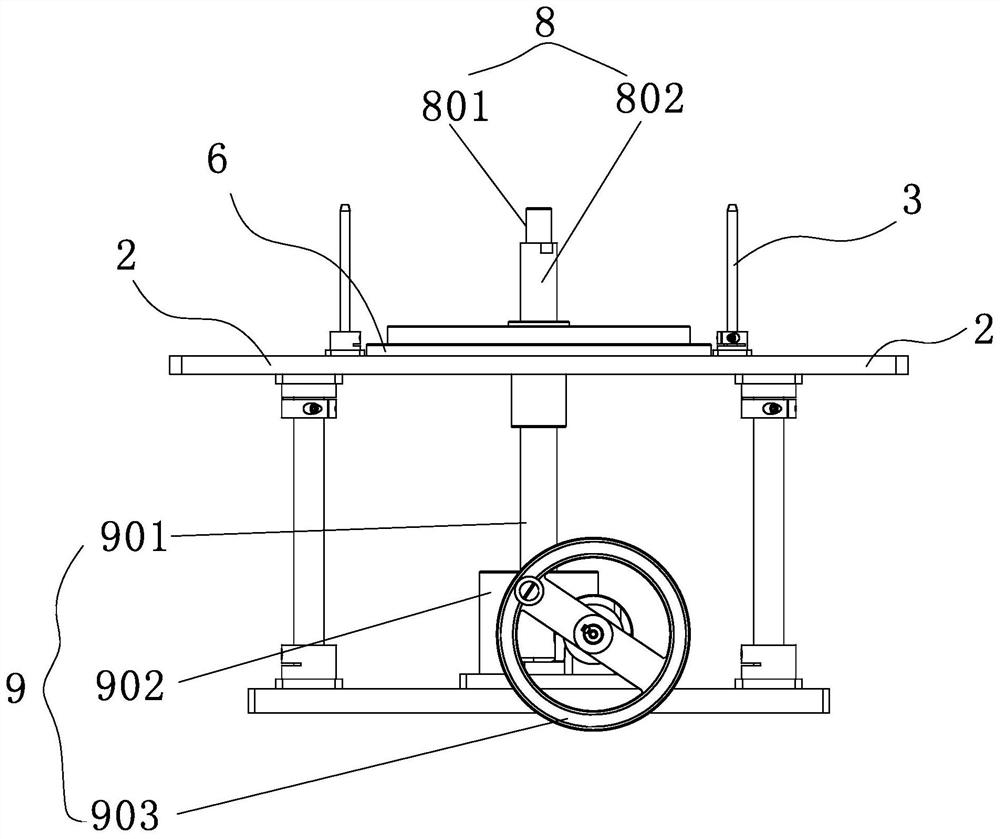

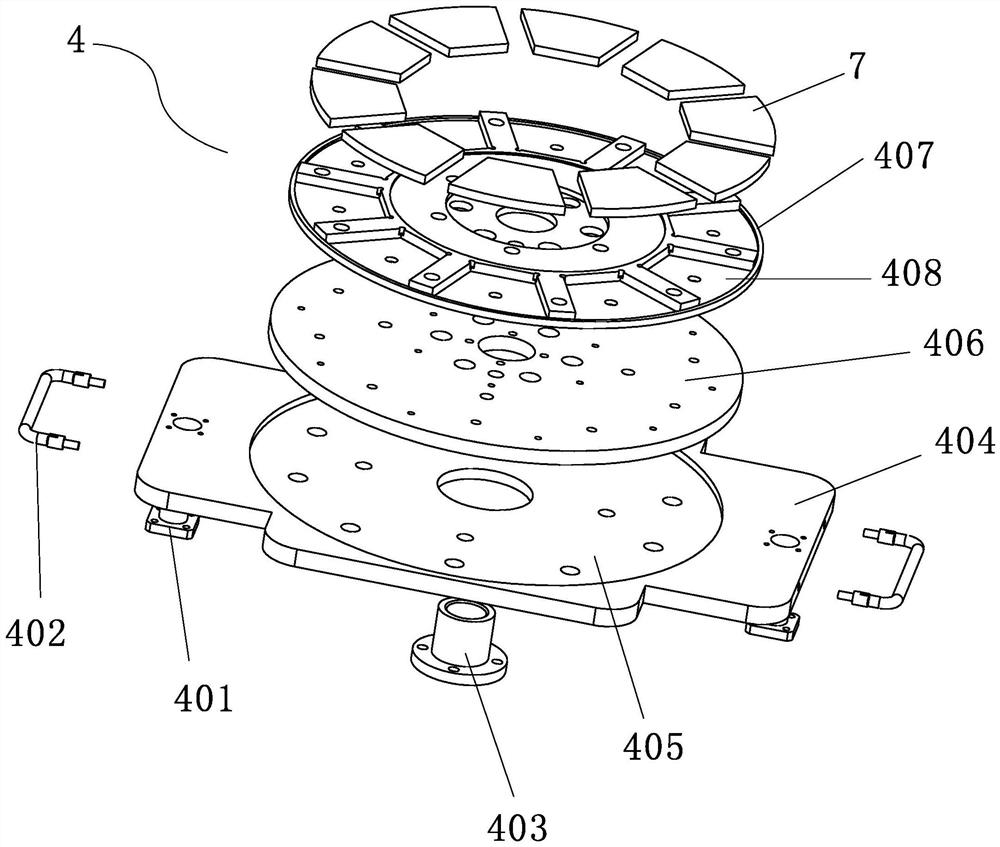

[0032] Such as figure 1 , image 3 , Figure 4In the shown embodiment 1, a disc motor rotor magnet assembly tooling includes a frame 1, a rotor disc support positioning platform 6 for installing a rotor disc support 5, and a magnet assembly positioning tool for installing a magnet 4. The elevator 9 used to control the lifting of the magnetic steel assembly and positioning tool 4 and the assembly guide mechanism that guides the magnetic steel assembly and positioning tool 4 are provided with a workbench 2 on the frame 1, and the rotor disk support positioning platform 6 is installed On the workbench 2, a positioning hole 501 is provided on the positioning platform 6 of the rotor disc support, and a positioning pin 10 for positioning the rotor disc support is arranged in the positioning hole 501; the magnetic steel assembly positioning tool 4 includes a magnetic steel positioning plate 407 , the magnetic backboard 406 and the fixing plate 404, the magnetic steel positioning pl...

Embodiment 2

[0038] The technical solution of embodiment 2 is basically the same as the technical solution of embodiment 1, the difference is that: the upper end of the upper shaft 801 is provided with a chamfering structure, and the guide column 3 is provided with the guide column 3 as the upper small The taper of the lower large structure facilitates the installation between the magnetic steel assembly positioning tooling 4 and the guide column 3 and the central shaft 8 .

Embodiment 3

[0040] The technical solution of embodiment 3 is basically the same as the technical solution of embodiment 1, the difference is that: the guide support sleeve 403 is fixed on the fixed plate 404, and the guide support sleeve 403 is fixed on the fixed plate 404 by bolts, the installation is convenient and quick and It is strong, and it is convenient to install the guide support sleeve 403 on different fixing plates 404 so as to adapt to the magnetic steel assembly positioning tool 4 of different sizes and models.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com