A High Power High Voltage Schottky Barrier Diode

A Schottky potential and diode technology, applied in the field of diodes, can solve problems such as the reduction of SSG capability, and achieve the effects of high SSG capability, reduced resistance, and high ESD capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

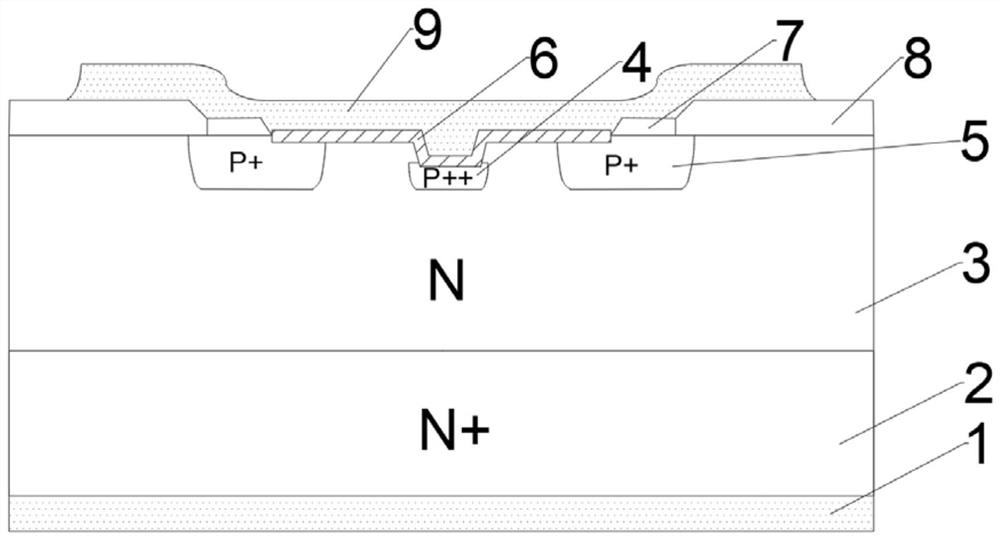

[0040] like Figure 1-2 As shown, a high-power high-voltage Schottky barrier diode, including from bottom to top: back metal layer 1, N+ substrate 2, N epitaxial layer 3, metal silicide layer 6, front metal layer 9; N epitaxial layer The upper part of 3 is provided with a heavily doped anode region 4 and a P+ guard ring 5, the guard ring 5 is arranged around the heavily doped anode region 4, a groove is opened on the upper surface of the N epitaxial layer 3, and the heavily doped anode region 4 is arranged in the groove At the bottom of the groove, the metal silicide layer 6 is arranged along the groove, the upper surface of the heavily doped anode region 4 and the guard ring 5 are in contact with the lower surface of the metal silicide layer 6, and the heavily doped anode region 4 at the bottom of the groove cooperates with the The metal silicide layer 6 and the front metal layer 9 form an independent ESD discharge area; a thin oxygen layer 7 is set between the guard ring 5 a...

Embodiment 2

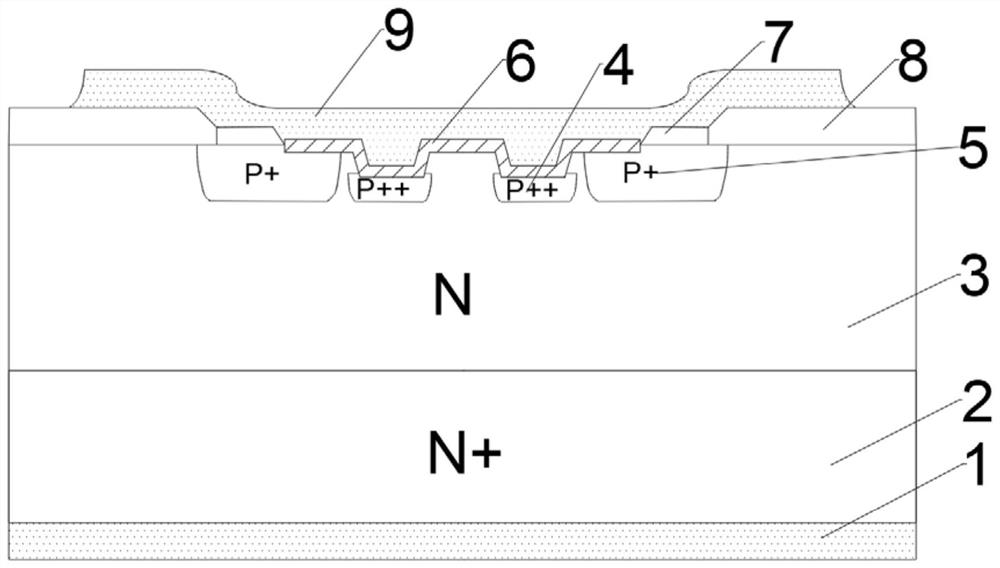

[0043] like Figure 3-4 As shown, a high-power high-voltage Schottky barrier diode, on the basis of the first embodiment, the area surrounded by the guard ring 5 is the active area, the active area is rectangular, and the corners of the active area are arc-shaped, There are four heavily doped anode regions 4 and they are distributed at the corners of the active region. The heavily doped anode regions 4 are fan-shaped and have a radius greater than that of the arc at the corners of the active region.

[0044] The above-mentioned technical solutions in the embodiments of the present application have at least the following technical effects or advantages:

[0045] 1. The upper part of the N epitaxial layer is provided with a heavily doped anode area, which forms an independent ESD discharge area in conjunction with the metal silicide layer and the front metal layer. This structure sets an independent ESD discharge area in the diode active area to reduce the impact on The influen...

Embodiment 3

[0049] A kind of diode preparation method that realizes the structure of above-mentioned embodiment, comprises the following steps:

[0050] Step 1: forming an N epitaxial layer on an N+ substrate;

[0051] Step 2: forming field oxygen on the N epitaxial layer;

[0052] Step 3: Form a protective ring and thin oxygen on the N epitaxial layer and field oxygen by photolithography, etching, implantation, glue removal, and annealing;

[0053] Step 4: forming grooves on the N epitaxial layer and field oxygen by photolithography and etching;

[0054] Step 5: Forming a heavily doped anode under the trench in the N epitaxial layer by implantation, glue removal, and annealing;

[0055] Step 6: Form contact holes on the N epitaxial layer, field oxygen, thin oxygen, and grooves by photolithography, etching, and glue removal, for forming metal silicide layer windows;

[0056] Step 7: forming a metal silicide layer on the contact hole by depositing a barrier metal layer, rapid thermal an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com