Vehicle oil filling port position recognition device and method

A recognition device and recognition method technology, applied in the direction of character and pattern recognition, instruments, computer parts, etc., can solve the problems of low degree of automation, heavy oil injection pipe, inconvenient manual operation, etc., achieve high degree of automation, shorten oil injection time, Dealing with high-risk effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

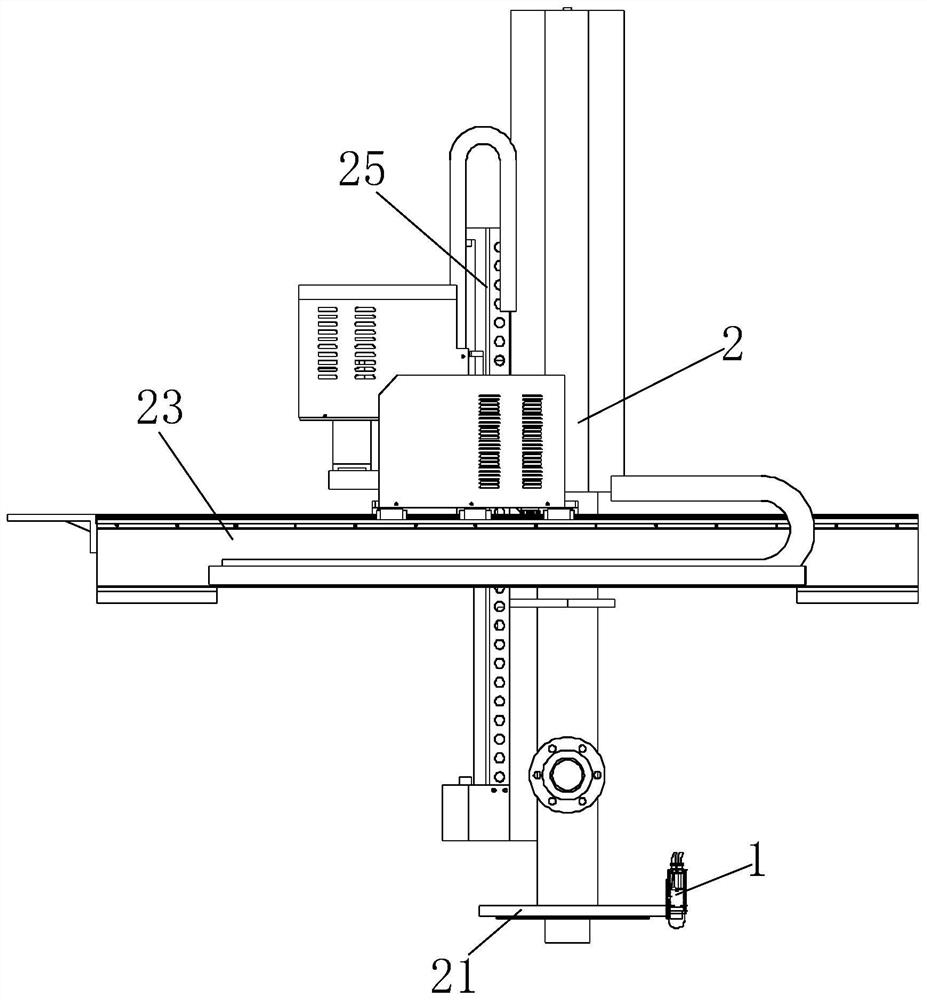

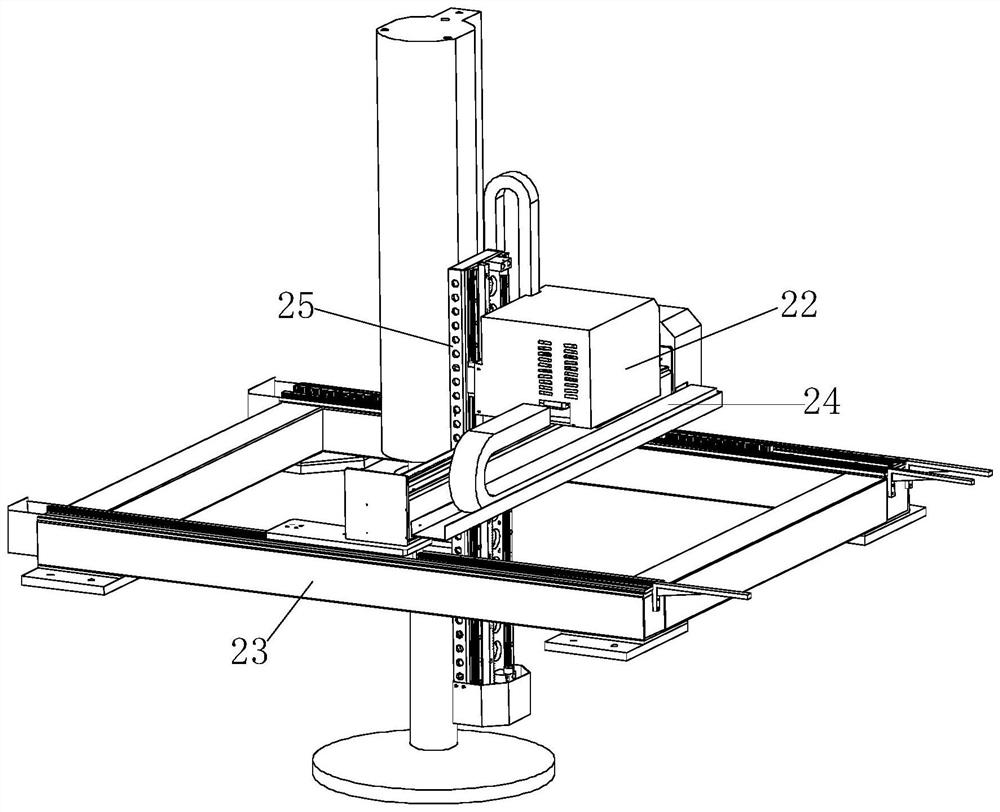

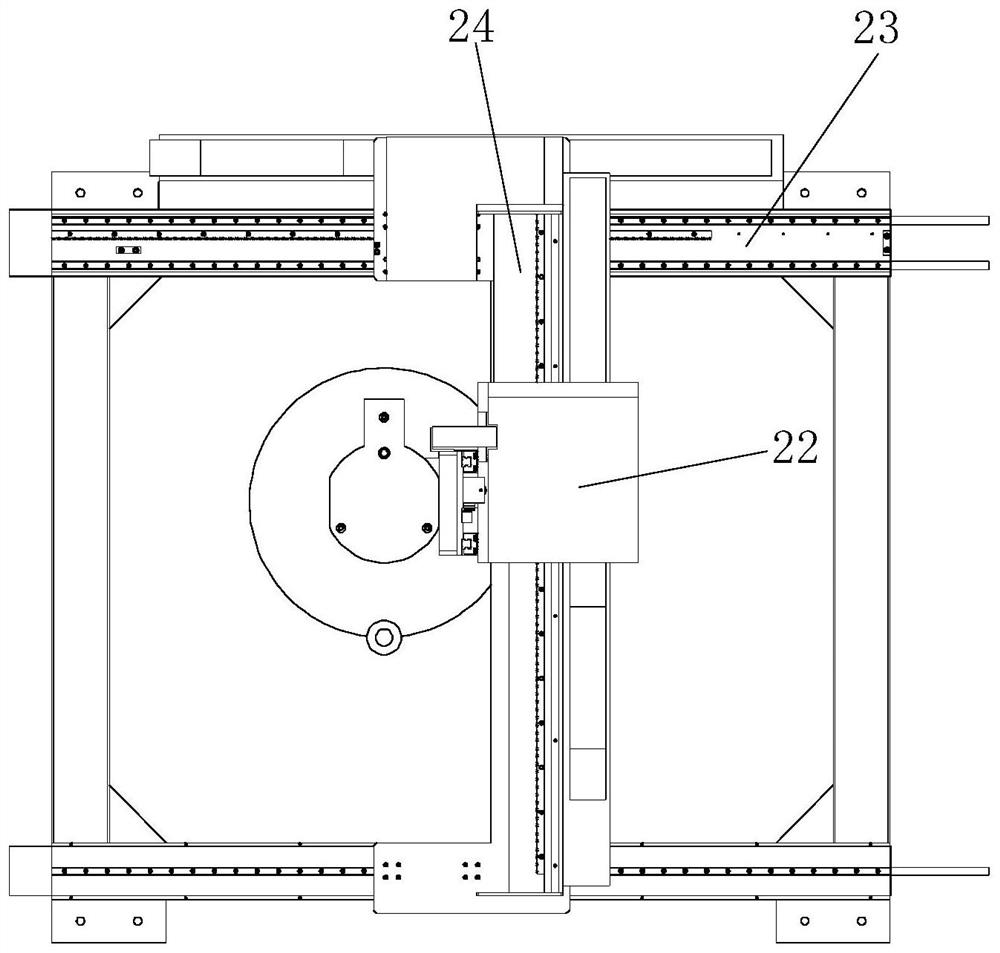

[0041] Example 1, see Figure 1 to Figure 3 , the first embodiment of the present invention provides a vehicle oil filling port position recognition device, including:

[0042] Identify component 1, take a picture of the area where the fuel filling port of the vehicle is located at least once, and obtain imaging information;

[0043] The microprocessor receives the imaging information and the coordinate information of the identification component 1 itself, processes the imaging information to obtain the position coordinates of the oil filling port, and calculates the distance that the three-axis moving component 2 needs to move in combination with the coordinate information of the identification component 1 itself;

[0044] The three-axis moving component 2 drives the identification component 1 to move horizontally and vertically;

[0045] The output end of the identification assembly 1 is connected with the input end of the microprocessor; the output end of the microprocessor ...

Embodiment 2

[0054] Embodiment 2, the second embodiment of the present invention provides a method for identifying the position of a fuel filling port of a vehicle, comprising the following steps:

[0055] (1) Identification component 1 takes a picture of the area where the oil filling port is located in the vehicle and obtains imaging information, and sends the imaging information and the self coordinate information of the identification component 1 to the microprocessor;

[0056] (2) The microprocessor receives the imaging information, processes the imaging information, and passes Z 0 Obtain the height from the oil filling port to the camera, where Z 1 is the distance between the oil filling port and the identification assembly 1, d is the diameter of the oil filling port on the imaging information, D is the actual diameter of the oil filling port, Z 0 is the distance from the identification component 1 to the film of the identification component 1; the microprocessor then combines th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com