Three-dimensional floating adjustable fixture

An adjustable and fixture technology, which is applied in the direction of manufacturing tools, workpiece clamping devices, liquid tightness measurement using liquid/vacuum degree, etc., can solve the problem that the quick connector cannot be automatically inserted into the threaded hole, etc., and achieves a simple and easy structure. Manufactured, functional and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

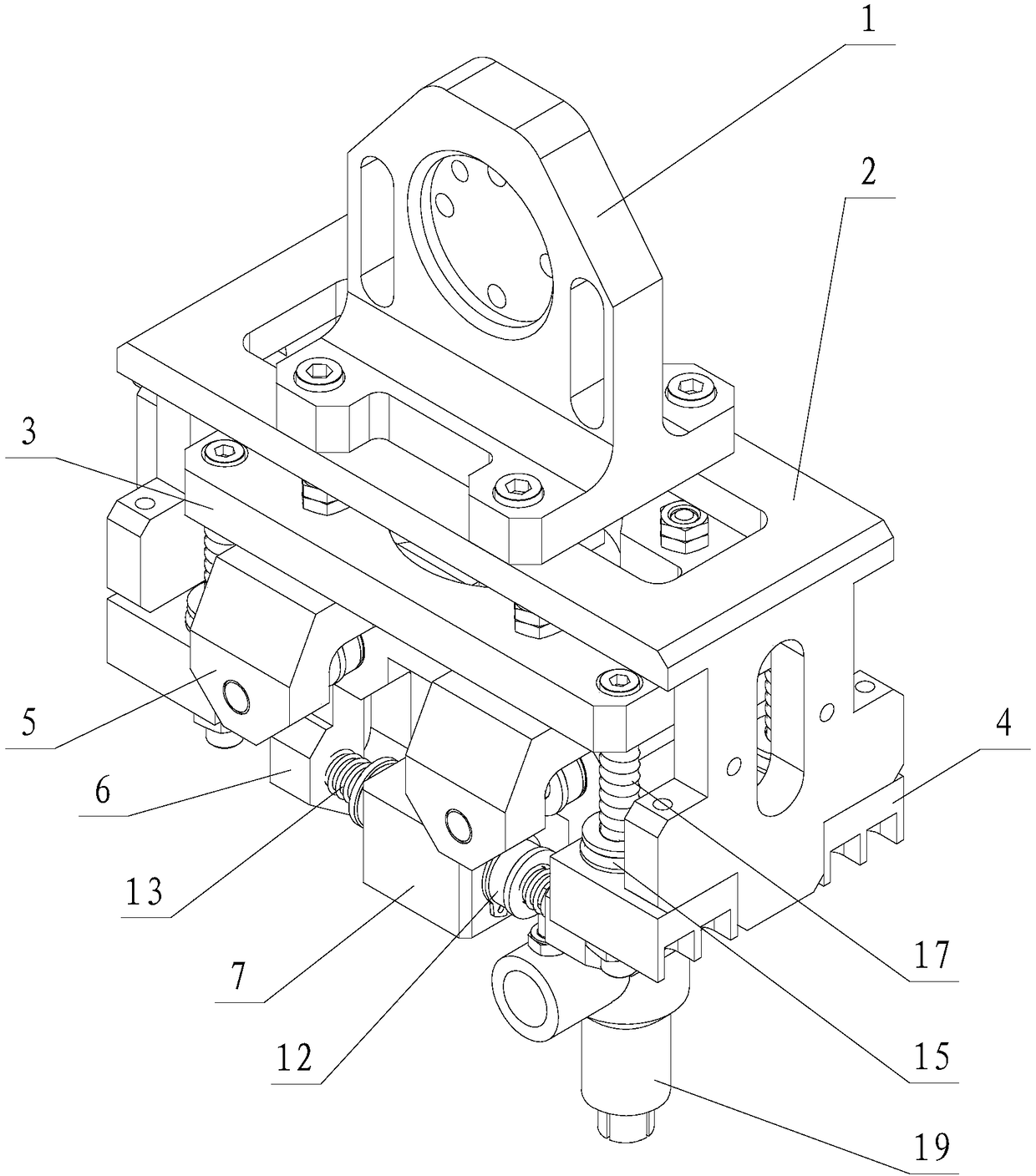

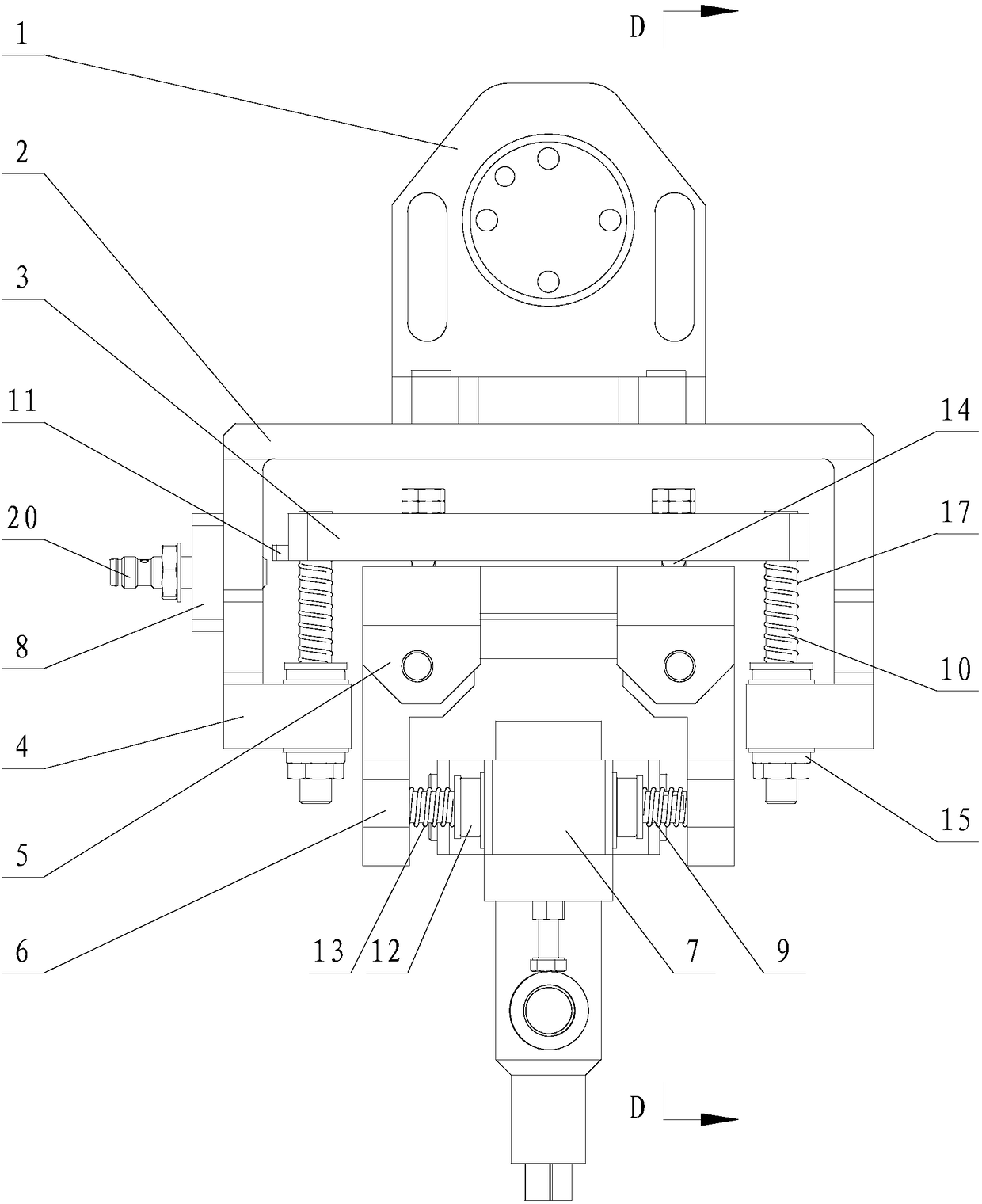

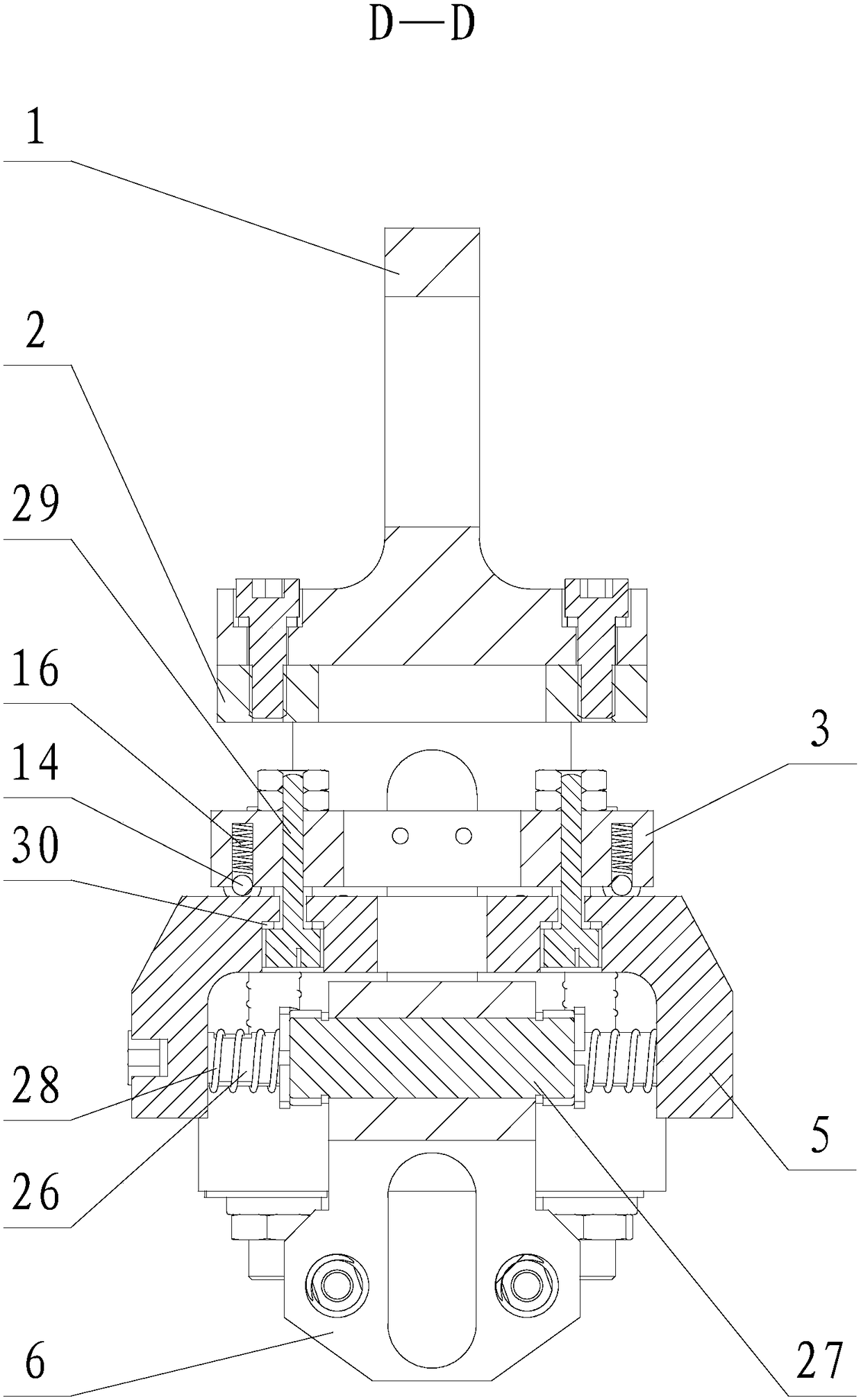

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0038] Such as Figure 1-16 As shown, the present invention includes a robot flange connecting plate 1, a floating double L connecting plate 2, a floating bottom plate 3, a bottom block 4, a Z-axis floating seat 5, a floating middle plate 6, a connecting block 7, a connecting plate 8, X Axis 9, Z axis 10, in-position detection block 11, X axis linear bearing 12, X axis spring 13, steel ball 14, short linear bearing 15, steel ball spring 16, long spring 17, quick connector 19, proximity sensor 20, Y axis 26. The Y-axis linear bearing 27 and the Y-axis spring 28, wherein the end face of the robot flange connection plate 1 is in an inverted "T" shape, and there are bolt holes at the four corners of the bottom plate, which are used to connect with the floating double L connection plate through bolts; The upper end of the robot flange connecting plate 1 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com