Gas cylinder volume detection method and system based on 3D vision technology

A detection method and technology for gas cylinders, which are used in volume measurement instruments/methods, testing of mechanical parts, container/cavity capacity measurement, etc., which can solve the problem of reduced accuracy, low measurement accuracy, repeated loading and hoisting of gas cylinders into water jackets, etc. problem, to achieve the effect of fast speed and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

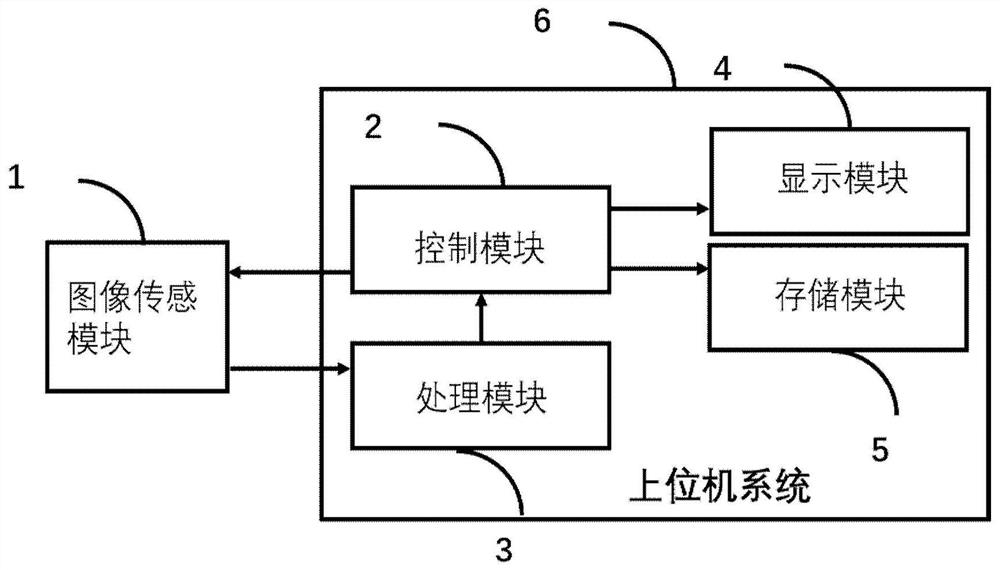

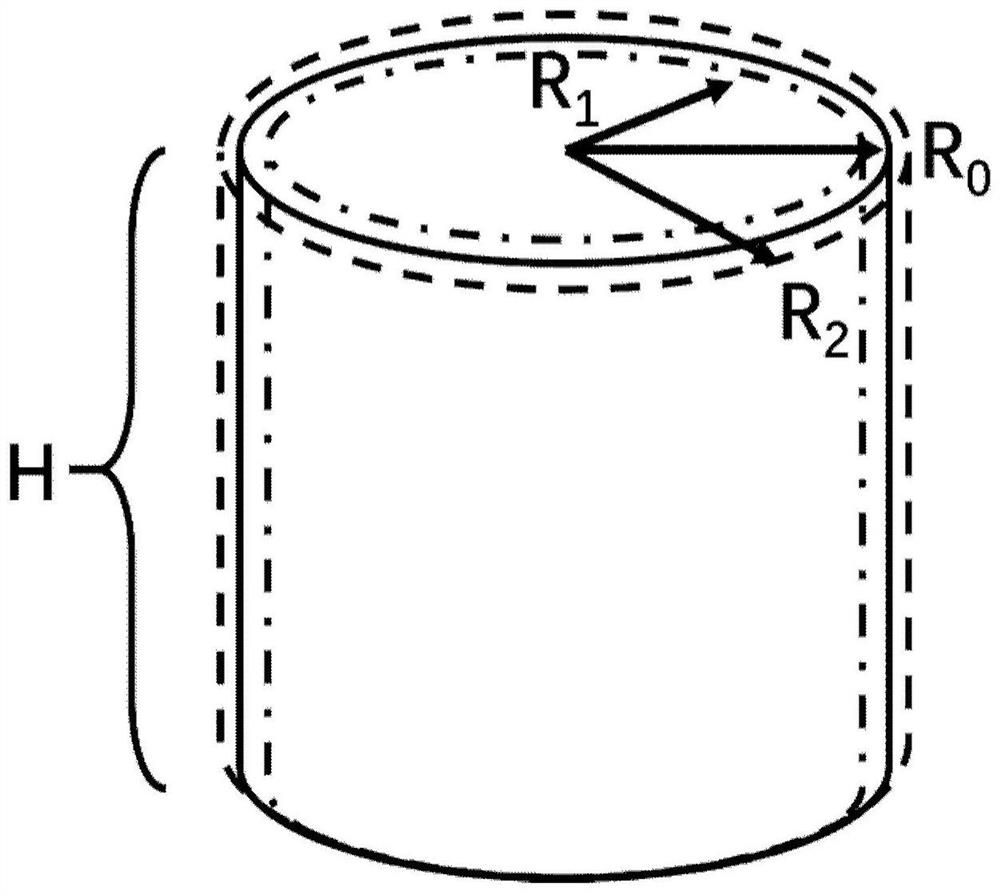

[0023] 3D vision is a new image acquisition technology based on the principles of structured light, triangulation, and time-of-flight. Compared with 2D vision, it can not only obtain grayscale images, but also obtain 3D point cloud images of object surface topography, so Not only can the contour changes caused by deformation be observed, but also the overall deformation of the cylinder surface can be obtained, so as to accurately calculate the residual volume deformation rate and other indicators.

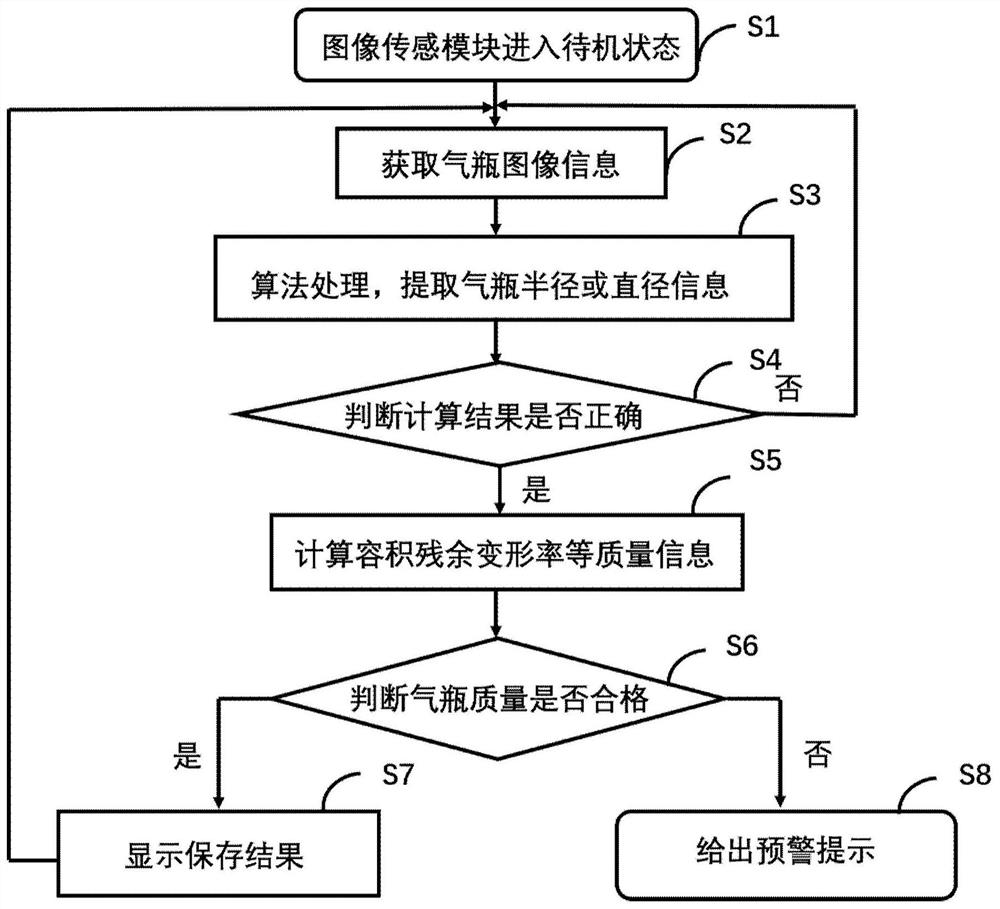

[0024] The invention discloses a gas cylinder volume detection method, comprising the following steps:

[0025] (1) Place the gas cylinder under test within the field of view, and collect information on the gas cylinder under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com