Energy dual-redundancy system and control method thereof

A control method and dual-redundancy technology, applied in the field of servo control systems, can solve problems such as the inability to meet the high reliability requirements of manned moon landings, the inability to provide energy for the electro-hydraulic servo system, and failure to achieve fault isolation. Switching and miscutting phenomenon, meeting high reliability requirements, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several changes and improvements without departing from the concept of the present invention. These all belong to the protection scope of the present invention.

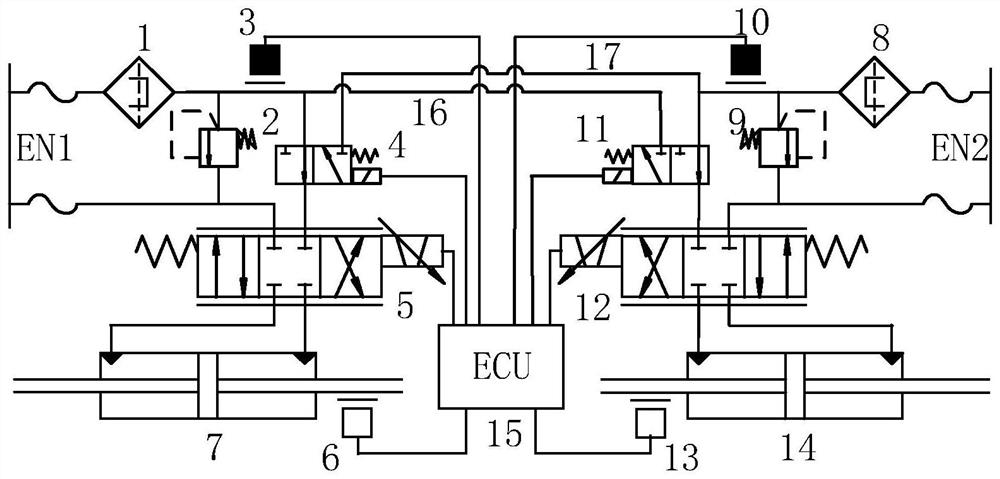

[0028] Such as figure 1 As shown, an energy dual redundancy system provided by the present invention includes: a controller 15, a main oil circuit and an auxiliary oil circuit.

[0029] The main oil circuit includes: the first essential oil filter 1, the first relief valve 2, the first energy selection valve 4, the first servo valve 5 and the first hydraulic cylinder 7, and the two ends of the first relief valve 2 are respectively connected to the first The high pressure circuit and low pressure circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com