Underground reciprocating type water injection device

A reciprocating and water flow channel technology, which is applied to the components of pumping devices for elastic fluids, wellbore/well components, variable capacity pump components, etc., which can solve the problems of large safety hazards, high costs, and large energy losses. problems, to achieve high reliability, low energy loss, and good boosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]In order to make the objectives, technical solutions, and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

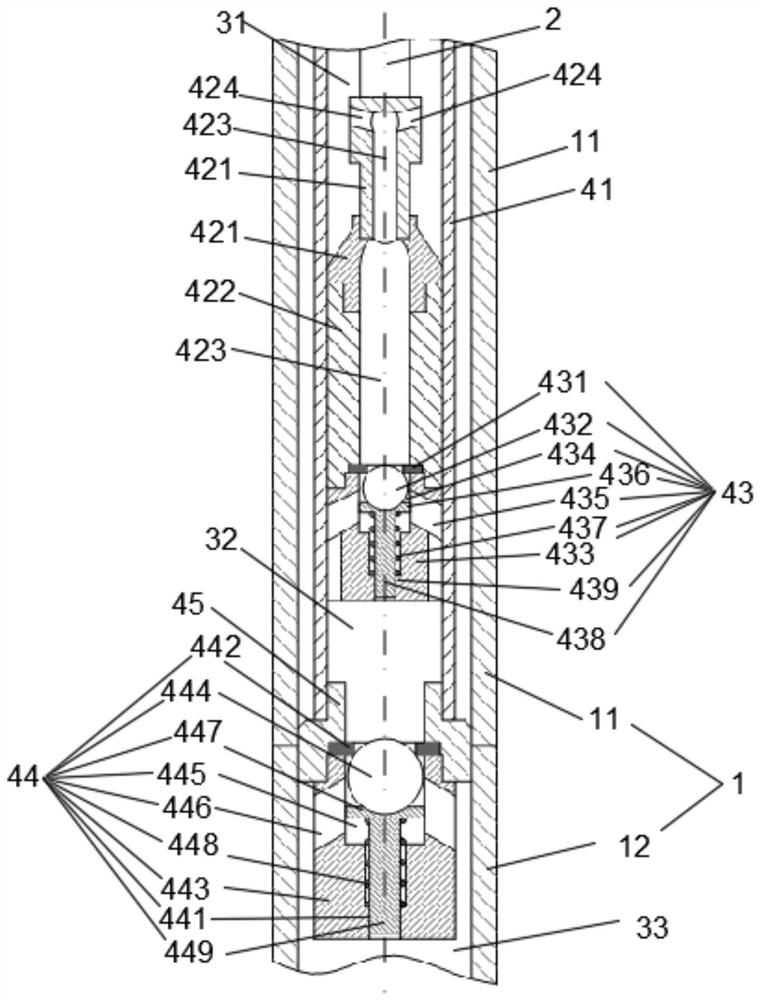

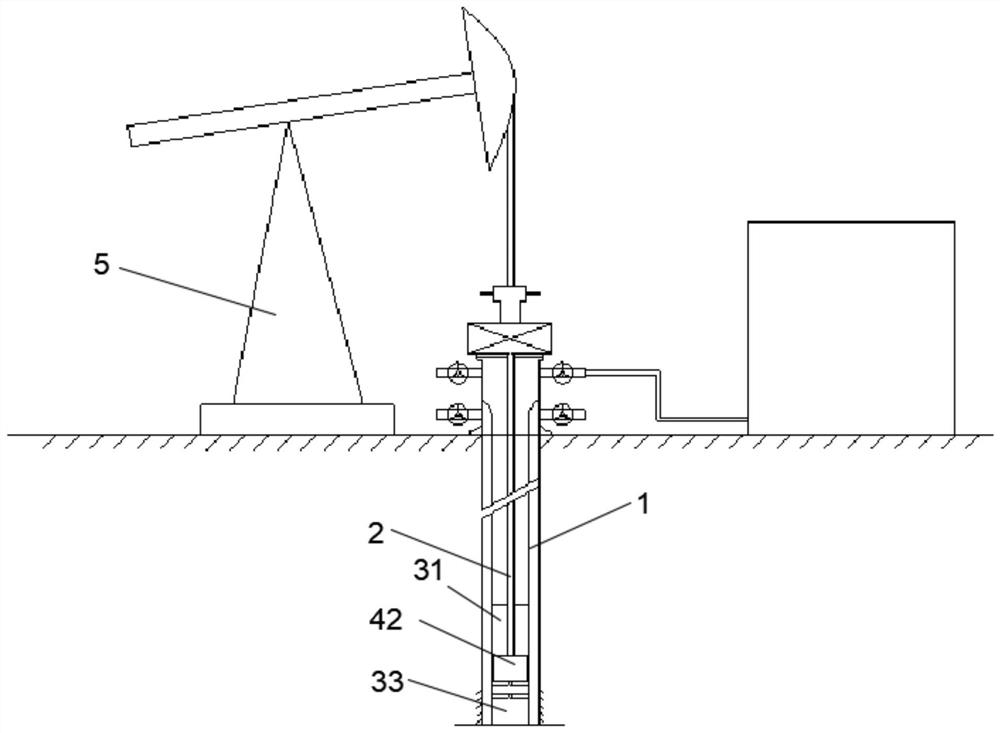

[0033]Such asfigure 1 ,figure 2As shown, the embodiment of the downhole reciprocating water injection device disclosed in the present invention includes a water injection pipe 1, a water injection rod string 2, an adapter 45, a driving device 5, a piston sleeve 41, a piston 422, a first one-way valve assembly 43 and The second one-way valve assembly 44.

[0034]In the above-mentioned downhole reciprocating water injection device, the water injection pipe 1 is fixed in the well connected to the oil layer 33, the water injection pipe 1 is fixedly connected to the well at the wellhead of the well, the lower end of the water injection pipe 1 is connected to the oil layer 33, the piston sleeve 41 and the adapter 45 are all set in the water injection pipe 1, the lower end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com