A dam spillway structure and its construction method

A technology for spillways and dams, applied in the field of spillways, can solve the problems of cavitation damage, low energy dissipation rate, and insufficient flow aeration on the stepped surface, and achieve the effect of reducing cavitation damage and improving efficiency and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

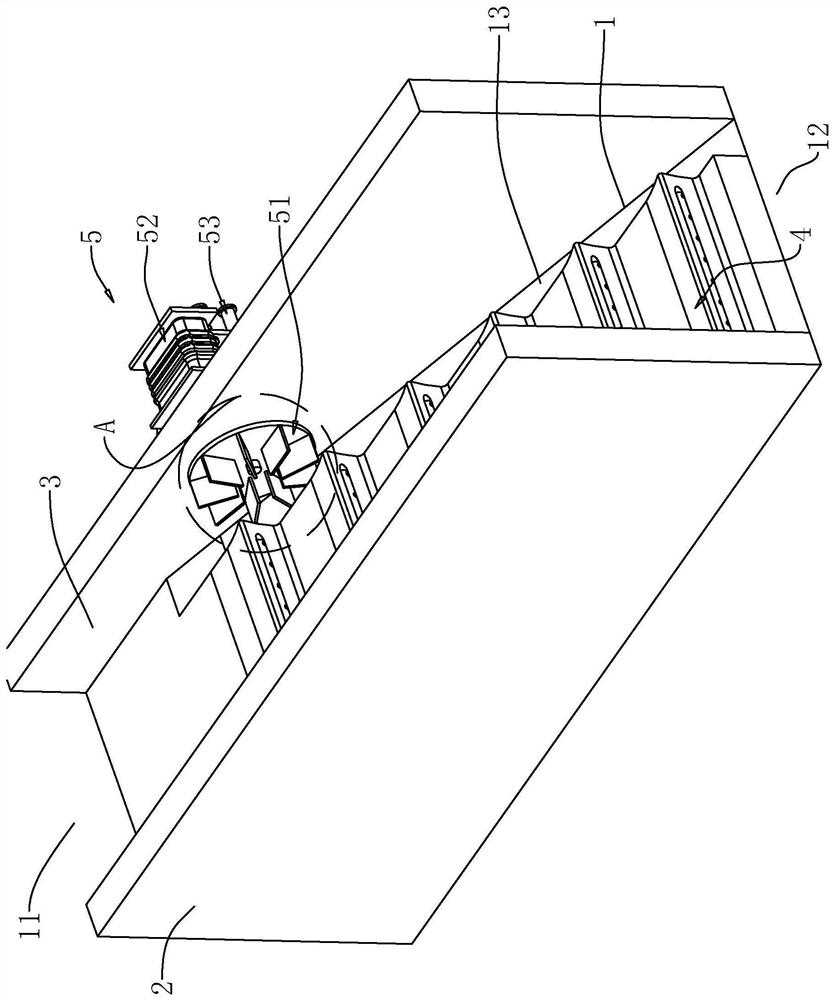

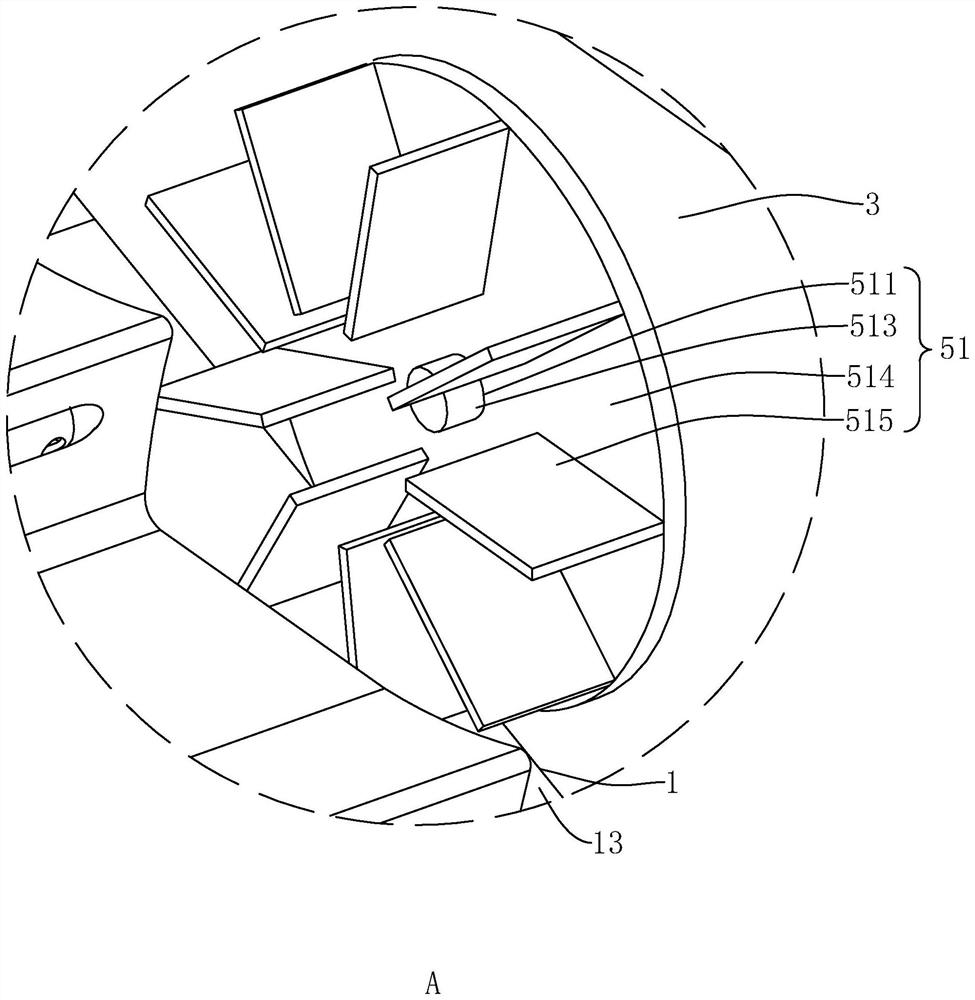

[0046] refer to figure 1 , a dam spillway structure, including a channel body bottom plate 1 extending obliquely, a first side plate 2 and a second side plate 3 formed on the inclined surface of the channel body bottom plate 1, and multiple side plates arranged on the channel body bottom plate 1 inclined surface A stepped body 4, an inflation mechanism 5 installed on the top of the second side plate 3.

[0047] refer to figure 1 , the bottom plate of the channel body 1 is arranged on an incline, the higher end of the channel body bottom plate 1 is the inlet 11, and the lower end of the horizontal position is the outlet 12, and the water flow flows out from the inlet 11 along the channel bottom plate 1 to the outlet 12; The first side plate 2 and the second side plate 3 are all formed on the top of the channel body bottom plate 1, the first side plate 2 and the second side plate 3 are all vertical extensions, and the first side plate 2 and the second side plate 3 are spaced ap...

Embodiment 2

[0071] refer to Figure 4 , Figure 5 , The difference between Embodiment 2 and Embodiment 1 is that the inflation mechanism 5 includes a rotating member 51 and an inflation body 6 . The specific structure of the rotating member 51 is the same as that of the rotating member 51 in the first embodiment.

[0072] refer to Figure 5 , The inflatable body 6 includes a mounting plate 61 , blades 62 , a casing 63 , and a circular tube 64 . The mounting plate 61 is fixedly sleeved on the rotating rod 513; the blade 62 is fixedly connected to the outer wall of the mounting plate 61 away from the second side plate 3, and the blade 62 is rotationally symmetrical along the axis of the rotating rod 513; the housing 63 is sleeved on the mounting plate 61. The outside of the plate 61 and the blade 62, the housing 63 is a hollow cylinder inside the housing 63, the axis of the housing 63 coincides with the axis of the rotating rod 513, and the outer wall of the housing 63 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com