A kind of high chroma automobile varnish and preparation method thereof

A high-chroma, automotive technology, applied in the coating and other directions, can solve the problem of unable to achieve the color brightness of the car body, and achieve the effect of plump appearance, high chroma, and improve the hardness of the paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

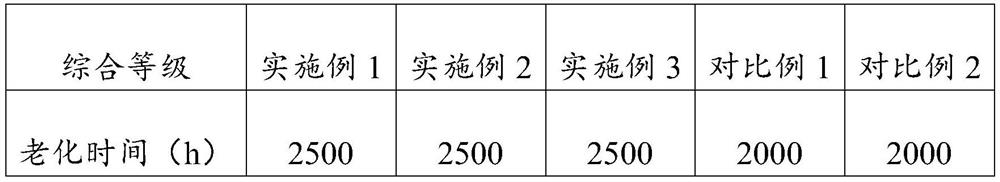

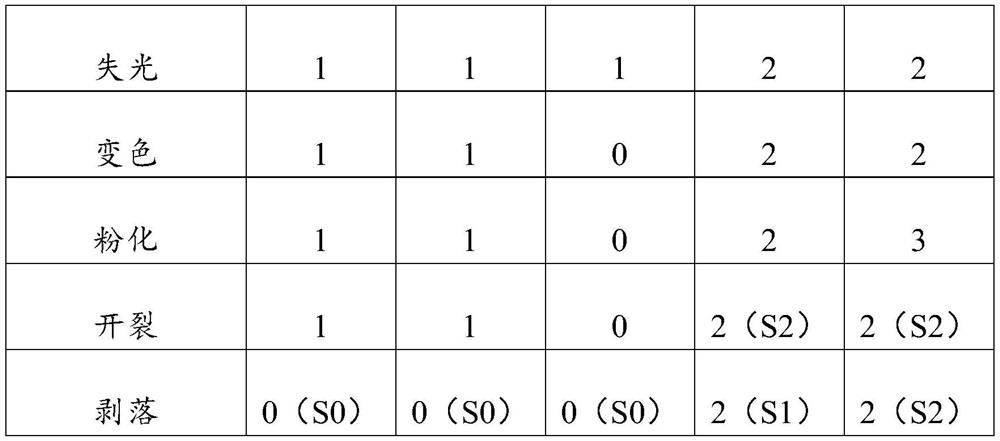

Examples

preparation example Construction

[0029] After weighing each component and parts by weight according to Table 1, the preparation method of the high chroma automotive varnish described in the examples and comparative examples comprises the steps:

[0030] (1) Stir and mix butyl acetate, propylene glycol methyl ether acetate and ethylene glycol diacetate evenly, and the stirring speed is 270r / min to obtain a mixed solution A;

[0031] (2) Add the dispersant to the mixed solution A obtained in step (1), and stir at a stirring speed of 270-330r / min, and a stirring time of 3min to obtain the mixed solution B;

[0032] (3) Add the PR179 CAB color chip to the mixed solution B obtained in step (2), and stir, the stirring speed is 720r / min, and the stirring time is 55min, to obtain the mixed solution C;

[0033] (4) Put the mixed liquid C through the sand mill, the speed of the sand mill is 1200r / min, and the cycle grinding time is 30min. After the fineness of the mixed liquid C is ≤8um, add resin, fluorine-modified ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com