Foaming material prepared from eucommia ulmoides latex and natural latex, method and application

A technology of natural latex and foaming materials, which is applied to the application of foaming materials in making pillow cores or latex pillows. To achieve the effect of good support, high support and good resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

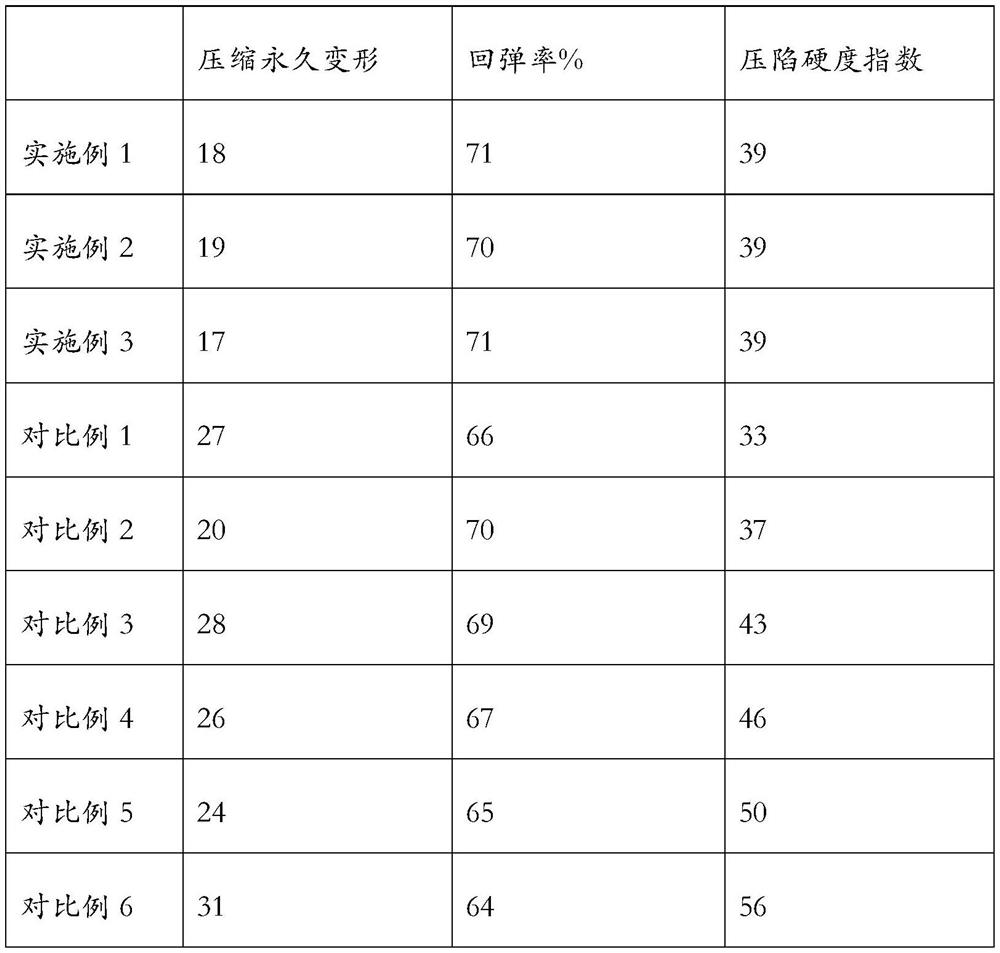

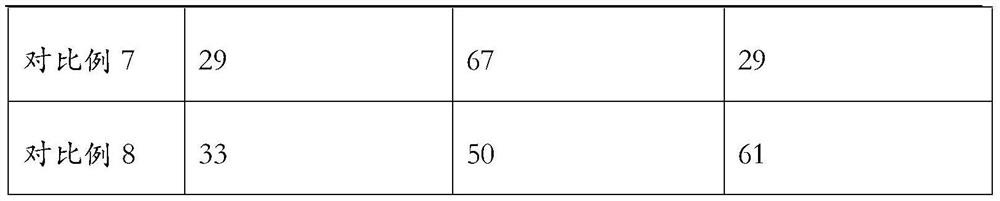

Examples

Embodiment 1

[0044] Taking the foaming pillow as an example, the process of using Eucommia latex and natural latex to make a foaming pillow includes the following steps:

[0045] (1) Get each raw material by the following parts by weight: Eucommia latex 30, natural latex 70, vulcanizing agent 0.6, accelerator 0.5, nucleating agent 7, antioxidant 0.2, activator 2;

[0046] (2) mix Eucommia latex and natural latex in (1), then add vulcanizing agent, promotor, nucleating agent, antioxidant, activating agent, adopt to mix with low-speed stirrer first, then adopt high-speed stirrer to mix; The rotation speed is 30rpm, the time is 5min, the rotation speed of the high-speed mixer is 100rpm, and the time is 3min; the above mixture is injected into the mold, vacuumized and filled with carbon dioxide, after foaming and vulcanization, washed with water, and the mold is opened when the mold is cooled to 10°C with super cold water. Take out the pillow core and dry it in an oven at 50° C. for 30 minutes...

Embodiment 2

[0050] (1) Get each raw material by the following parts by weight: Eucommia latex 30, natural latex 70, vulcanizing agent 0.6, accelerator 0.5, nucleating agent 7, antioxidant 0.2, activator 2;

[0051] (2) mix Eucommia latex and natural latex in (1), then add vulcanizing agent, accelerator, nucleating agent, antioxidant, active agent, adopt low-speed mixer to mix earlier, adopt high-speed mixer to mix again; The rotating speed of low-speed mixer It is 30rpm, the time is 5 minutes, the speed of the high-speed mixer is 100rpm, and the time is 3 minutes; inject the above mixture into the mold, vacuumize and fill with carbon dioxide, after foaming and vulcanization, wash with water, and open the mold when the mold is cooled to 10°C with super cold water , take out the pillow core and dry it in an oven at 50° C. for 30 minutes to obtain a foamed pillow core.

[0052] The conditions of the supercritical process are: pressure 10MPa, swelling time 3h, foaming temperature 60°C, pressu...

Embodiment 3

[0054] (1) Get each raw material by the following parts by weight: Eucommia latex 30, natural latex 70, vulcanizing agent 0.6, accelerator 0.5, nucleating agent 7, antioxidant 0.2, activator 2;

[0055] (2) mix Eucommia latex and natural latex in (1), then add vulcanizing agent, accelerator, nucleating agent, antioxidant, active agent, adopt low-speed mixer to mix earlier, adopt high-speed mixer to mix again; The rotating speed of low-speed mixer It is 30rpm, the time is 5 minutes, the speed of the high-speed mixer is 100rpm, and the time is 3 minutes; inject the above mixture into the mold, vacuumize and fill with carbon dioxide, after foaming and vulcanization, wash with water, and open the mold when the mold is cooled to 10°C with super cold water , take out the pillow core and dry it in an oven at 50° C. for 30 minutes to obtain a foamed pillow core.

[0056] The conditions of the supercritical process are: pressure 30MPa, swelling time 0.6h, foaming temperature 90°C, pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com