String binding machine

A belting machine and belting technology, which is applied in the direction of winding strips, sending objects, thin material processing, etc., can solve the problems of lack of tightening force, influence of belt surface smoothness, cumbersomeness, etc., and achieve the effect of precise movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

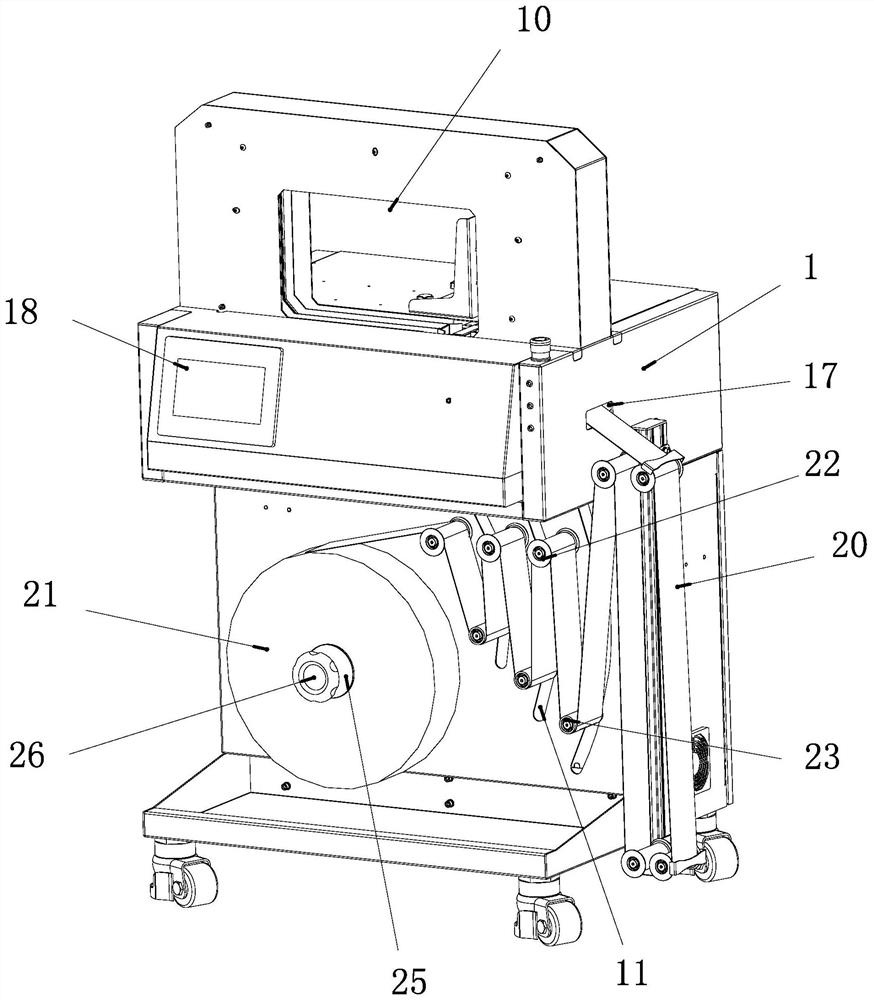

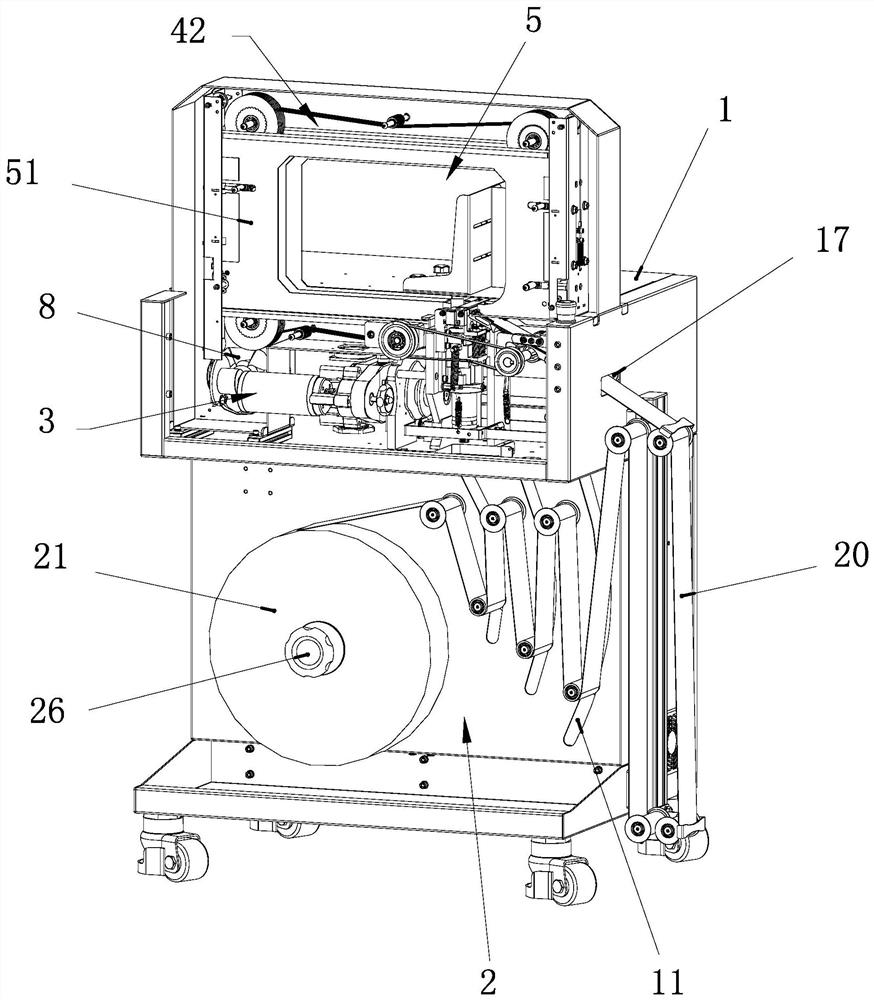

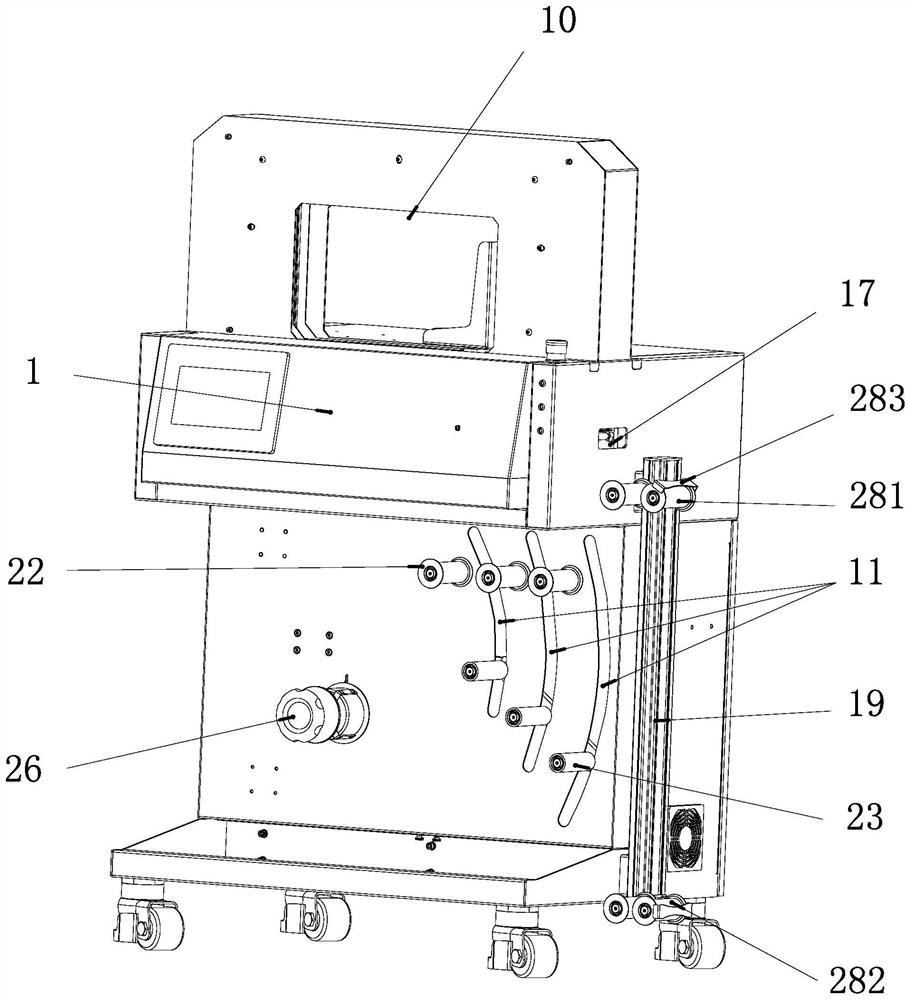

[0056] The present invention is described in detail below in conjunction with accompanying drawing, see Figure 1-Figure 14 :

[0057] A belting machine such as figure 1 with figure 2 As shown, including frame 1, frame 1 front side is provided with storage belt mechanism (for storing belt 20, and belt 20 is supplied to looping mechanism when needed), internally is provided with looping mechanism (for The belt 20 advances along an endless track 42, and forms a loop connected end to end), a tightening mechanism (for reversely tightening the belt 20, and the loop formed by the belt 20 is tightly bound on the product to be bound ), a fusion welding mechanism (for welding the head and tail ends of the loop into one), a tape cutting mechanism (which is used to cut off the still connected belt 20 other than the loop), and a control system for controlling the work of the above-mentioned mechanism.

[0058] The side on the frame 1 is provided with an inlet 17 for the belt to enter,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com