Material lifting device for highway repair

A material and highway technology, which is applied in the field of material lifting devices for highway repairs, can solve the problems of large digging resistance, easy slippage of bucket belts, and inability to control the amount of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings, so that those of ordinary skill in the art can implement it after referring to this specification.

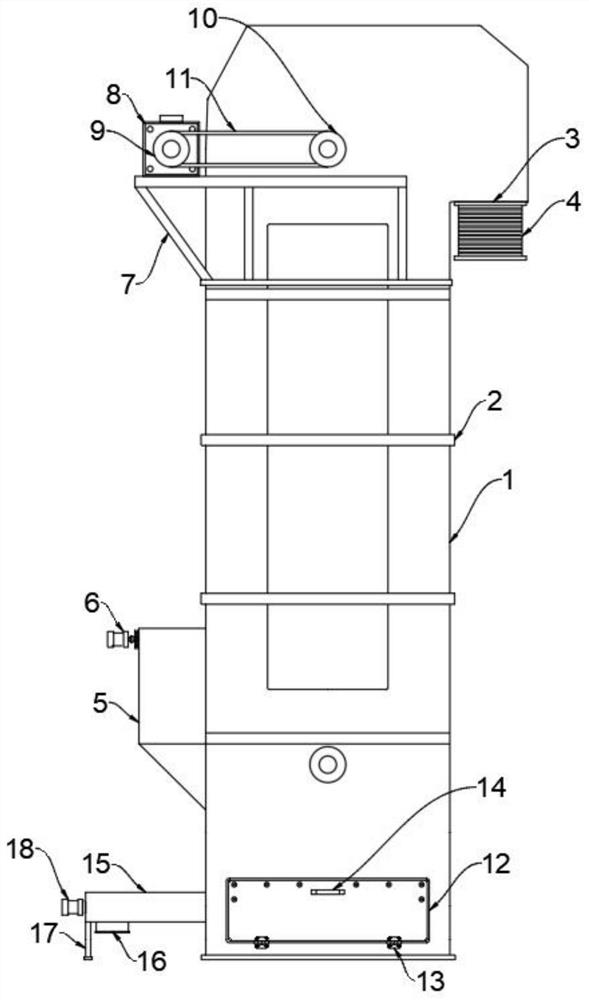

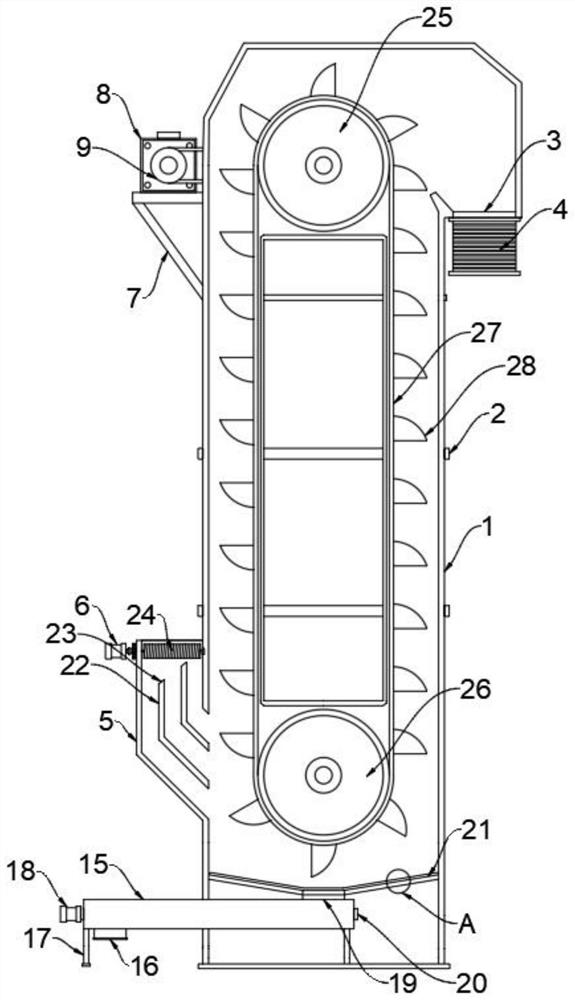

[0037] Such as Figure 1-7 Shown, a kind of material hoisting device for road restoration, comprising:

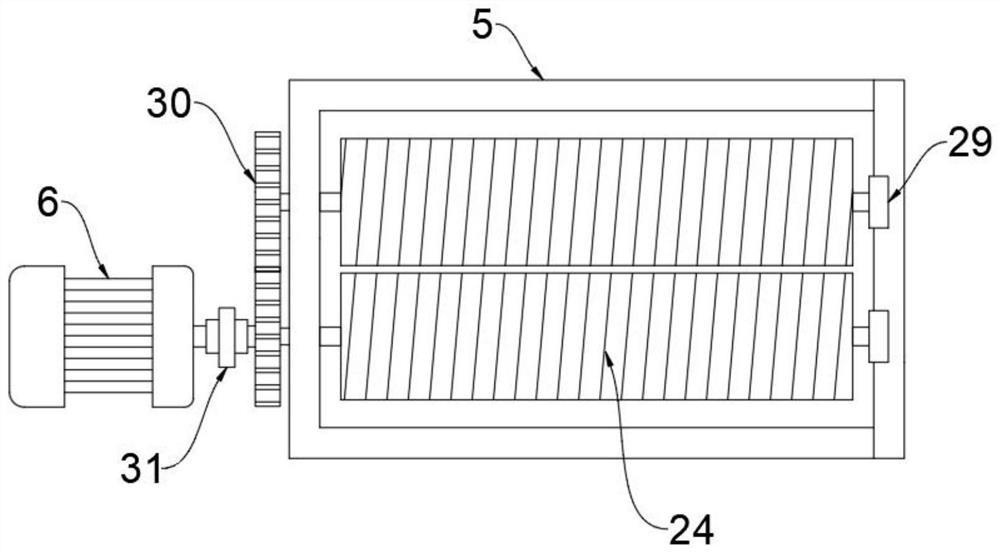

[0038] The main body of the lifting device 1, and the feed hopper 5 arranged on one side of the main body of the lifting device 1; the splitter plate 22, which is arranged inside the feed hopper 5, has an integral structure with the feed hopper 5, and There are two diverter plates 22 that can divide the material into three strands, and enter the interior of the main body 1 of the lifting device through three feed ports of different heights, so as to avoid material accumulation in one feed port; the screw conveyor 15 is arranged on the The lower end of the main body 1 of the lifting device, and one end of the screw feeder 15 penetrates and extends to the outside of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com