Automatic metal cutting device

A metal cutting and cutting table technology, applied in positioning devices, metal processing, metal processing equipment, etc., can solve the problems of low degree of automation, low cutting efficiency, high labor intensity, etc., and achieve high degree of automation, low labor intensity, and reduced The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

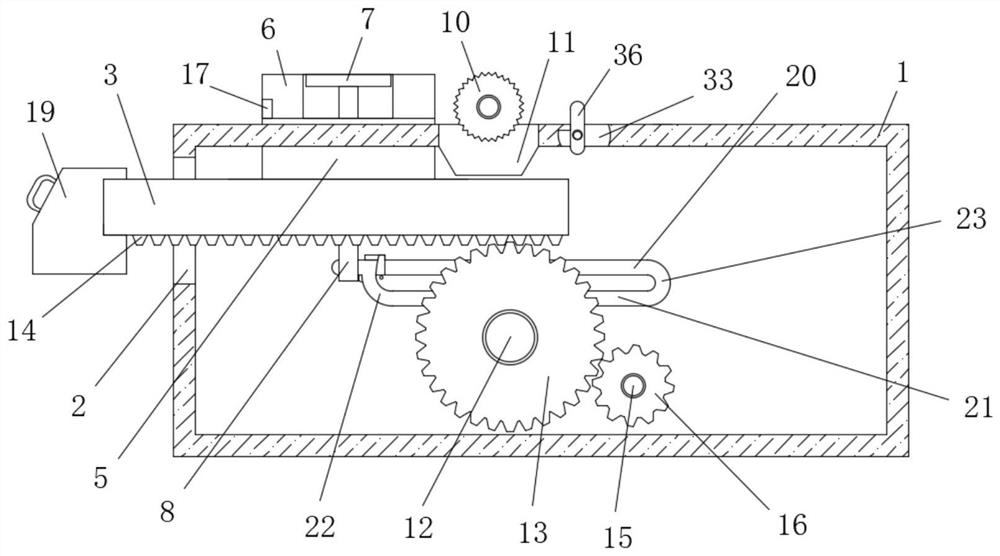

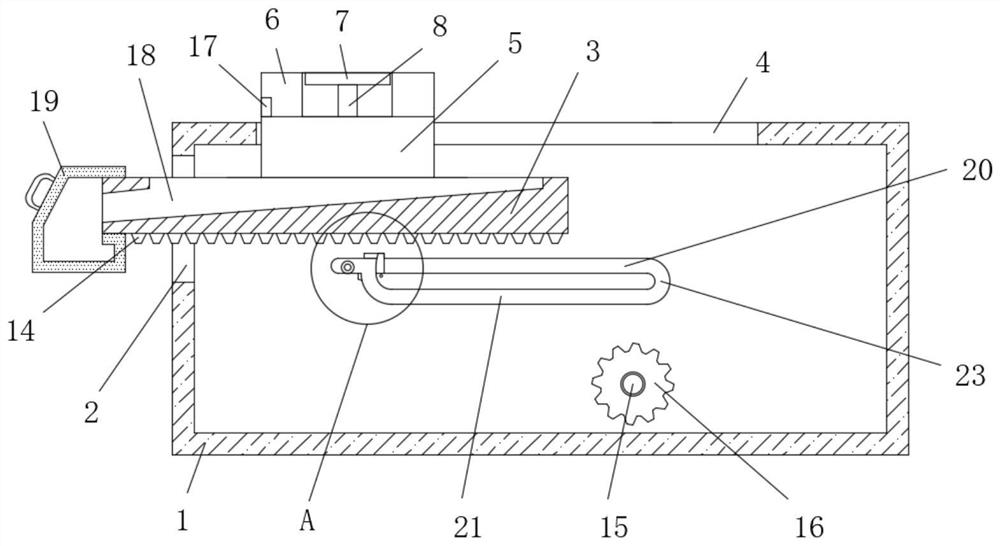

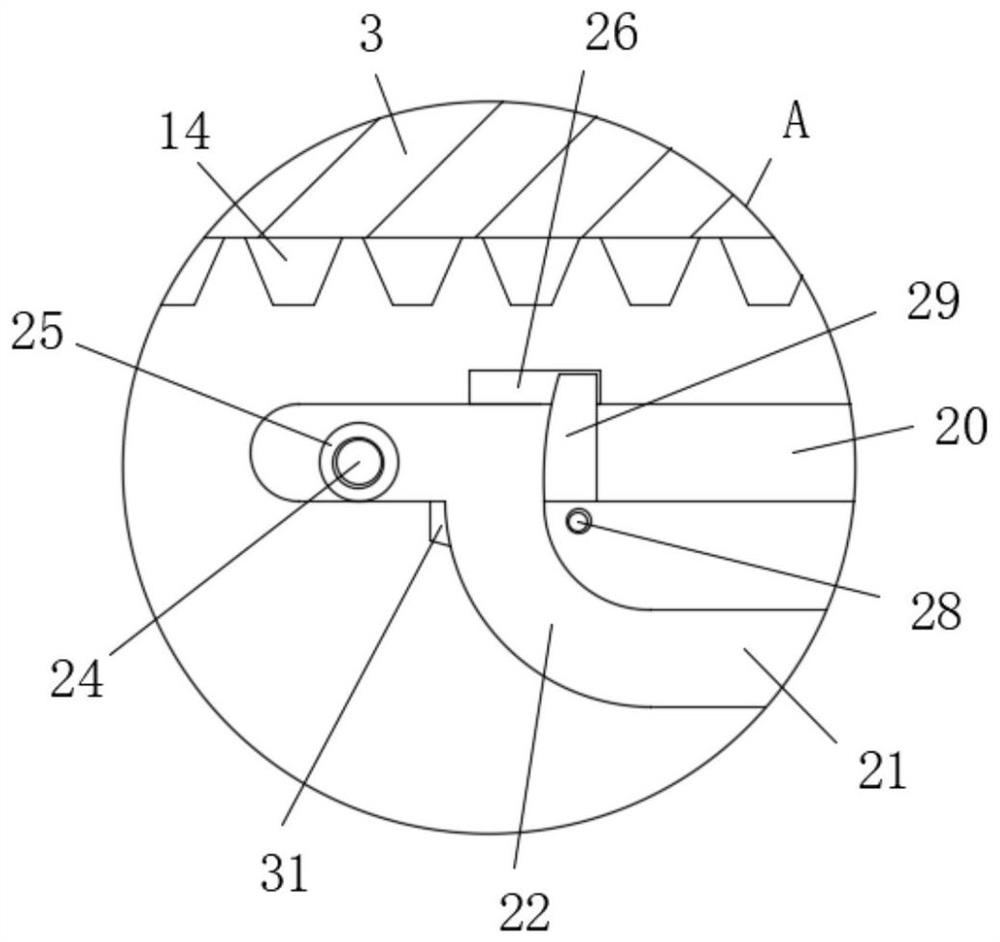

[0033] refer to Figure 1-8 , an automatic metal cutting device, including a cutting table 1, and the cutting table 1 is a hollow structure, a through hole 2 is opened on one side of the cutting table 1, and a moving plate 3 is slidably connected in the through hole 2, and the cutting table 1 Two moving holes 4 are opened symmetrically on the top, one side of the top of the moving plate 3 extends to the inside of the cutting table 1 and two moving blocks 5 are fixedly connected symmetrically, and one side of the two moving blocks 5 passes through the corresponding moving holes 4 respectively And both extend to the top of the cutting table 1, the tops of the two moving blocks 5 are fixedly connected with a baffle plate 6 on the side away from each other, and the tops of the two baffle plates 6 are slidably connected with a pressure plate 7 on the side close to each other. The bottom of the pressing plate 7 is fixedly connected with a pressing rod 8, and the bottom ends of the t...

Embodiment 2

[0035] Further improved on the basis of embodiment one:

[0036] In the present invention, the drive assembly includes a first rotating rod 12 that is rotatably connected to the inside of the cutting table 1. A large gear 13 is fixedly sleeved on the first rotating rod 12. A rack 14 is provided at the bottom of the moving plate 3, and the rack 14 Engage with the large gear 13, the bottom of the inner wall of one side of the cutting table 1 is fixedly connected with a servo motor 15, the output shaft of the servo motor 15 is fixedly provided with a pinion 16, and the pinion 16 is meshed with the large gear 13, and the start The servo motor 15 can drive the bull gear 13 to realize differential rotation through the meshing motion of the pinion 16 and the bull gear 13. When the bull gear 13 rotates, the meshing motion with the rack 14 can drive the moving plate 3 to move.

[0037] In the present invention, the top of the moving plate 3 is provided with a debris diversion groove 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com