Automatic assembling device for upper shell of engine thermostat

A technology of automatic assembly and thermostat, applied in the direction of assembly machines, metal processing, metal processing equipment, etc., can solve the problems of high work intensity, uneven assembly accuracy, low efficiency, etc., to improve the quality of finished products, convenient and fast operation, The effect of simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

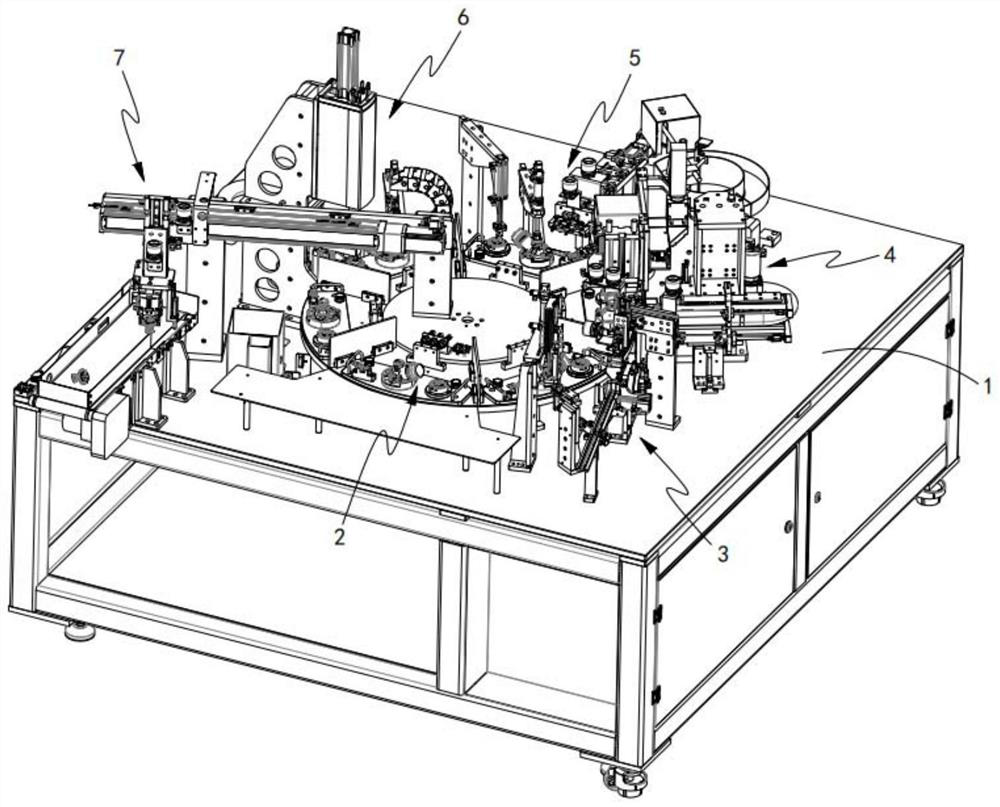

[0082] Such as Figures 1 to 5 As shown, an automatic assembly device for an upper housing of an engine thermostat includes a workbench 1, and also includes:

[0083] The turntable transfer assembly 2, the turntable transfer assembly 2 is arranged on the workbench 1, and the workbench 1 is sequentially provided with an upper casing feeding station 11 and a magnet feeding station along the circumference of the turntable transfer assembly 2 12. The first welding station 13, the wiring pin feeding station 14, the second welding station 15, and the discharging station 16. The turntable transfer assembly 2 includes a fixed disk 21, a turntable 22 and a housing tooling 23. The fixed disk 21 is fixedly arranged on the workbench 1, the rotating disk 22 is arranged coaxially with the fixed disk 21, and the rotating disk 22 is free to rotate, and the housing tooling 23 is arranged on the edge of the circumference of the rotating disk 22 , the turntable 22 drives the housing tooling 23 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com