Method for predicting thermal cycle parameters of cold and hot multi-wire composite submerged arc welding of large steel structural part

A technology of steel structural parts and welding thermal cycle, applied in arc welding equipment, welding equipment, welding accessories, etc., can solve the problem of high cost of thermal cycle parameter measurement, and achieve the effect of reducing test cost and workload

Inactive Publication Date: 2021-01-29

SHANGHAI ZHENHUA HEAVY IND +1

View PDF5 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] In view of the above-mentioned defects in the prior art, the purpose of the present invention is to provide a method for predicting the thermal cycle parameters of cold and hot multi-wire composite submerged arc welding of large-scale steel structure parts, in order to accurately obtain the welding thermal influence of large-scale thick-plate steel structure parts The thermal cycle curve of the zone can solve the problem that the measurement cost of thermal cycle parameters is too high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

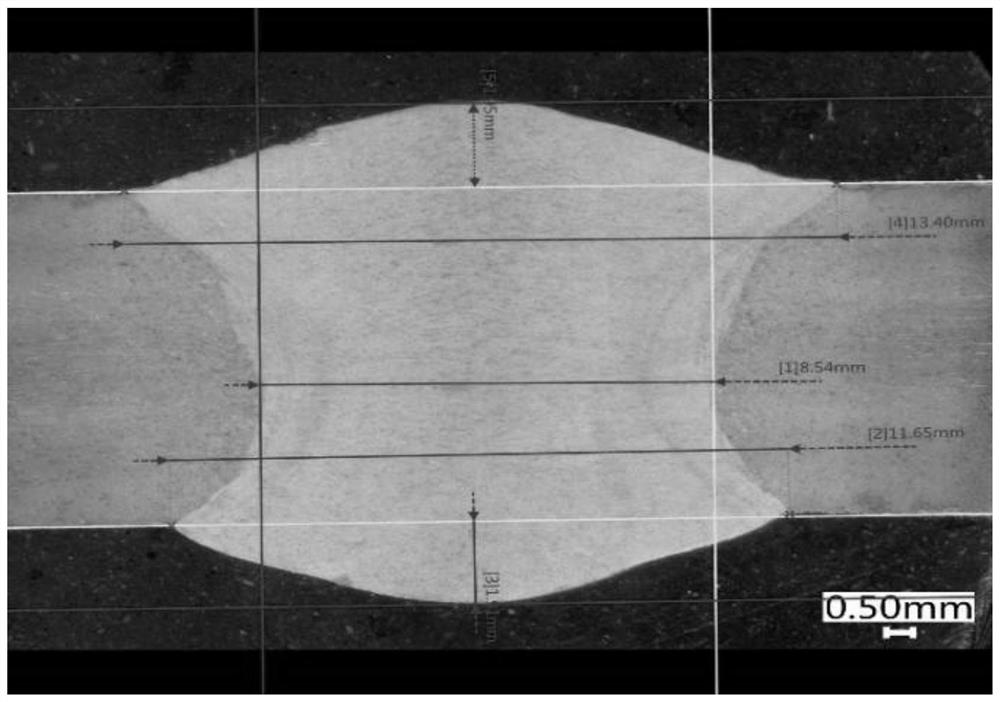

[0054] The welding method involved in the embodiment is cold / hot multi-wire composite submerged arc welding for the butt joint of the panels, and the temperature measurement method adopts the method of punching holes in the front of the thermocouple. First, record the jointing conditions of the panel: the length of the panel is 3000mm, the width is 2000mm, and the thickness is 8mm. The welding specifications are shown in Table 1 above.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

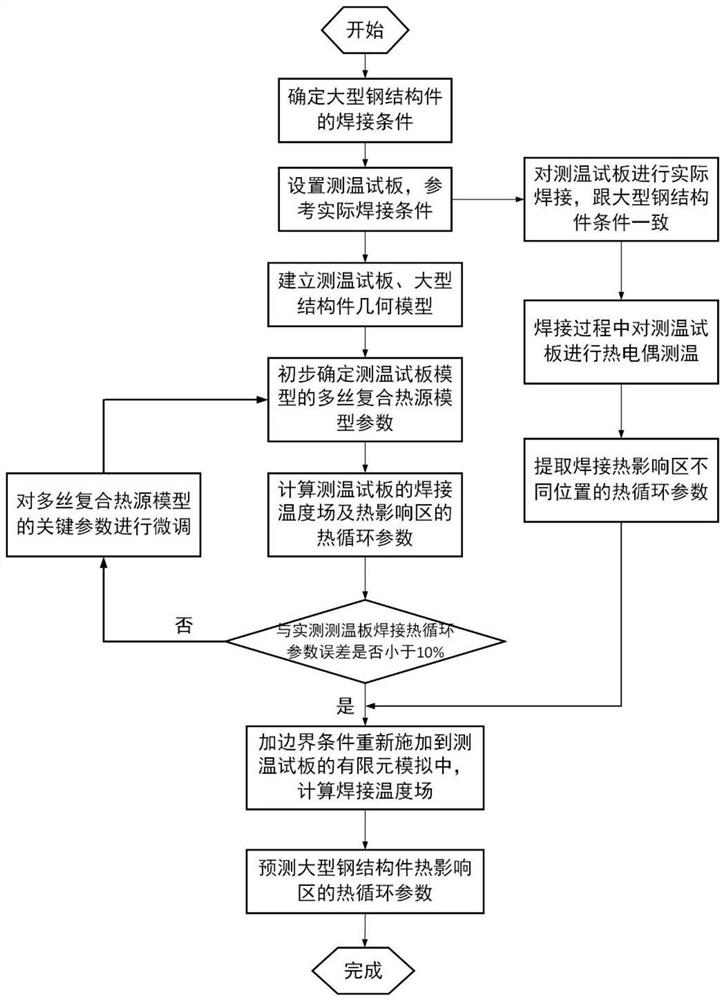

The invention discloses a method for predicting thermal cycle parameters of cold and hot multi-wire composite submerged arc welding of a large steel structural part. The method comprises the steps of(1) determining welding conditions of the large steel structural part; 2) welding a temperature measuring plate sample, and measuring an actual weld joint and a heat affected zone through metallographic analysis; 3) setting up a thermocouple temperature measurement system for calibration; 4) modeling the temperature measuring plate sample; 5) establishing a three-wire hybrid welding heat source model; 6) setting boundary condition parameters of the three-wire hybrid welding heat source model; 7) calculating the welding temperature field distribution of a temperature measuring plate sample model, and extracting the thermal cycle parameter of a certain position of the heat affected zone; (8) comparing the thermal cycle parameters with the thermal cycle parameters of the actually measured temperature measuring plate sample, if less than 10%, entering the step 9), and if greater than 10%, returning to the step 6) to finely adjust the parameters, and recalculating; and 9) newly adding boundary conditions and re-applying the boundary conditions to the temperature measuring plate sample model. According to the method, the problem that the thermal cycle parameter measurement cost is too high is solved.

Description

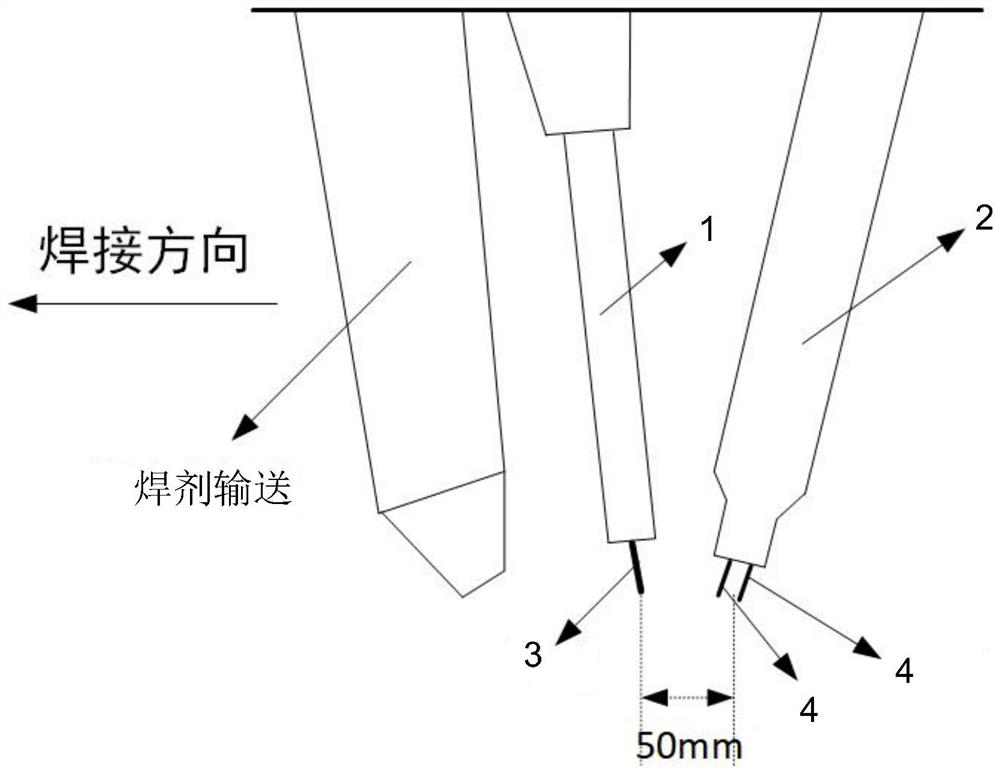

technical field [0001] The invention relates to a method for predicting welding cycle parameters, more specifically, a method for predicting thermal cycle parameters for cold and hot multi-wire composite submerged arc welding of large steel structures. Background technique [0002] The welding process is a special local heating and cooling process, and the coarse-grained zone in the heat-affected zone is in an overheated state, the austenite grains are heated and grow seriously, and complex and coarse structures are produced after cooling, with low toughness and overheating. The coarse-grained region is generally a region with weak mechanical properties, which is prone to welding defects such as catalysis and cracks. Therefore, accurate measurement and prediction of the thermal cycle curves of each zone in the weld heat-affected zone is the basis for welding metallurgical analysis, and it is also the basis for welding numerical simulation calculation and prediction of metall...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23K9/18B23K9/095B23K9/32

CPCB23K9/18B23K9/095B23K9/32

Inventor 张华军于治水兰虎付俊张培磊叶欣吴頔张天理

Owner SHANGHAI ZHENHUA HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com