Preparation method for asphalt concrete

A technology of asphalt concrete and asphalt, applied in chemical instruments and methods, filter screens, grids, etc., can solve the problems of crushed stone clogging screen holes, easy inclusion of large pieces of crushed stone in finished materials, affecting the processing and use of finished materials, etc. , to achieve the effect of reducing the requirement of symmetrical size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

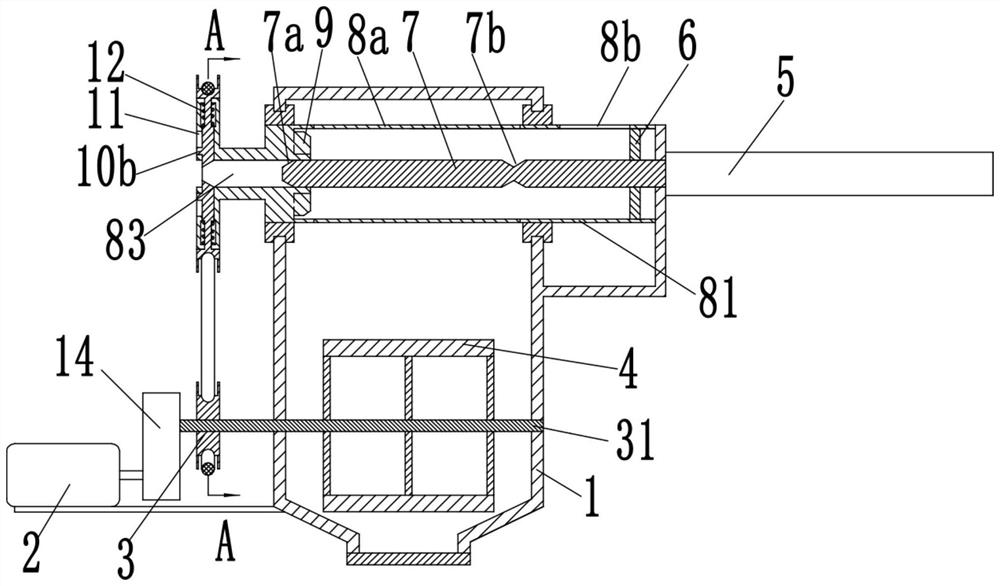

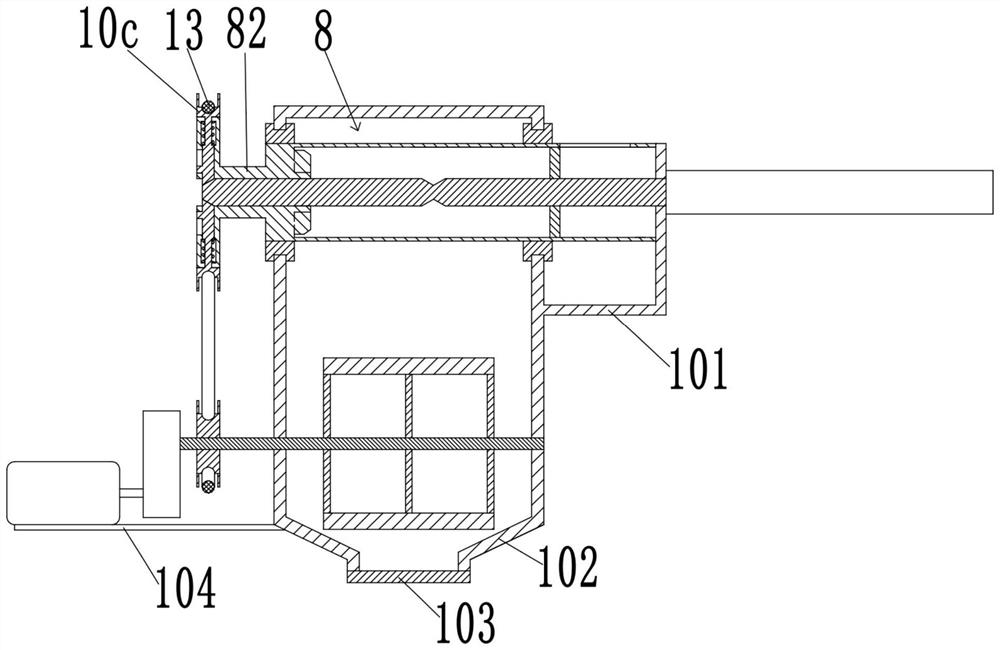

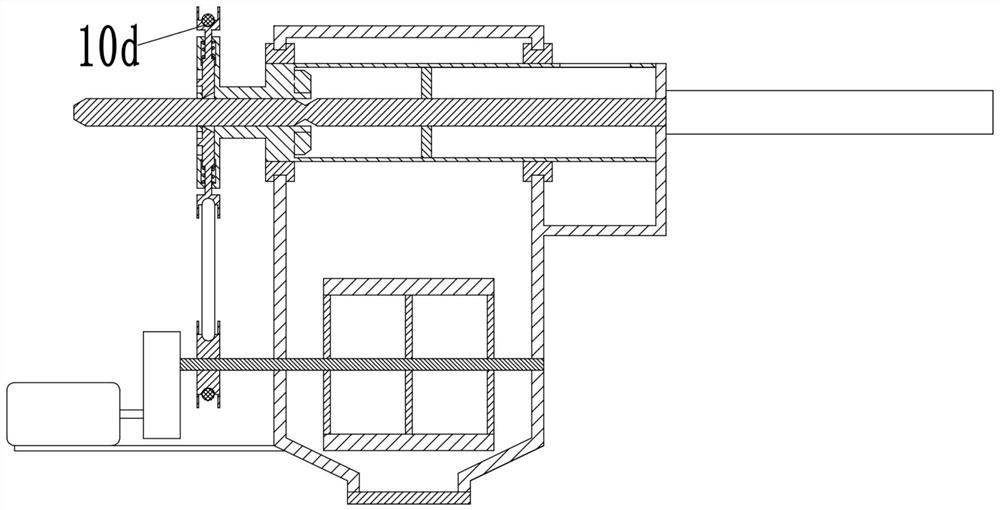

[0028] see Figure 1-6 Shown, the invention provides a kind of preparation method of asphalt concrete, comprises the following steps:

[0029] Step 1: Add heated asphalt into the housing 1, and control the rotating shaft 31 to drive the stirring rod 4 located in the housing 1 to stir the asphalt;

[0030] Step 2: Put the broken stones into the screen mechanism 8, and control the electric push rod 5 to stretch out to drive the push plate 6 and the push rod 7 to move to the left, and push the broken stones to the screen when the push plate 6 moves to the left In the net 8a, when the push rod 7 moves to the left, the belt pulley assembly connected with the screen cloth mechanism 8 is connected with the rotating shaft 31, and the rotating shaft 31 drives the screen cloth 8a to rotate through the belt pulley assembly, so that the crushed stones in the screen cloth 8a can be continuously Sieve falls into bitumen;

[0031] Step 3: continue to control the extension of the electric p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com