Vertical shaft fracture type grouting curtain excavation unloading analog simulation test system and method

A grouting curtain, excavation and unloading technology, applied in the field of shaft grouting curtain, can solve the problems of difficulty in meeting the simulation needs of unloading stress path, without considering the effect of fillings in cracks, unable to simulate crack-type grouting curtain, etc. , to achieve the effect of real excavation unloading stress path, important application value and promotion value, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Example 1. Shaft fissure-type grouting curtain excavation and unloading similar simulation test system

[0053] Such as Figure 8 The vertical shaft fissure type grouting curtain excavation and unloading similar simulation test system shown includes a rigid loading chamber side wall 21, a base 18, an axial pressure piston 19, an upper pressing plate 16, a lower pressing plate 17, an external pressure oil pump 24 and an internal pressure oil pump 25, the base 18 is connected to the lower part of the rigid loading chamber side wall 21 through a load-bearing snap ring 22; the lower pressure plate 17 is installed on the upper surface of the base 18, and the axial pressure piston 19 is installed on the The top of the rigid loading chamber side wall 21; the space surrounded by the base 18, the rigid loading chamber side wall 21 and the axial pressure piston 19 is a high pressure loading chamber 15; the power output end of the axial pressure piston 19 is connected to the The ...

Embodiment 2

[0056] Example 2. Similar Simulation Test Method for Shaft Crack Type Grouting Curtain Excavation and Unloading

[0057] (A) pouring of the surrounding rock sample of the prefabricated crack thick-walled cylindrical shaft;

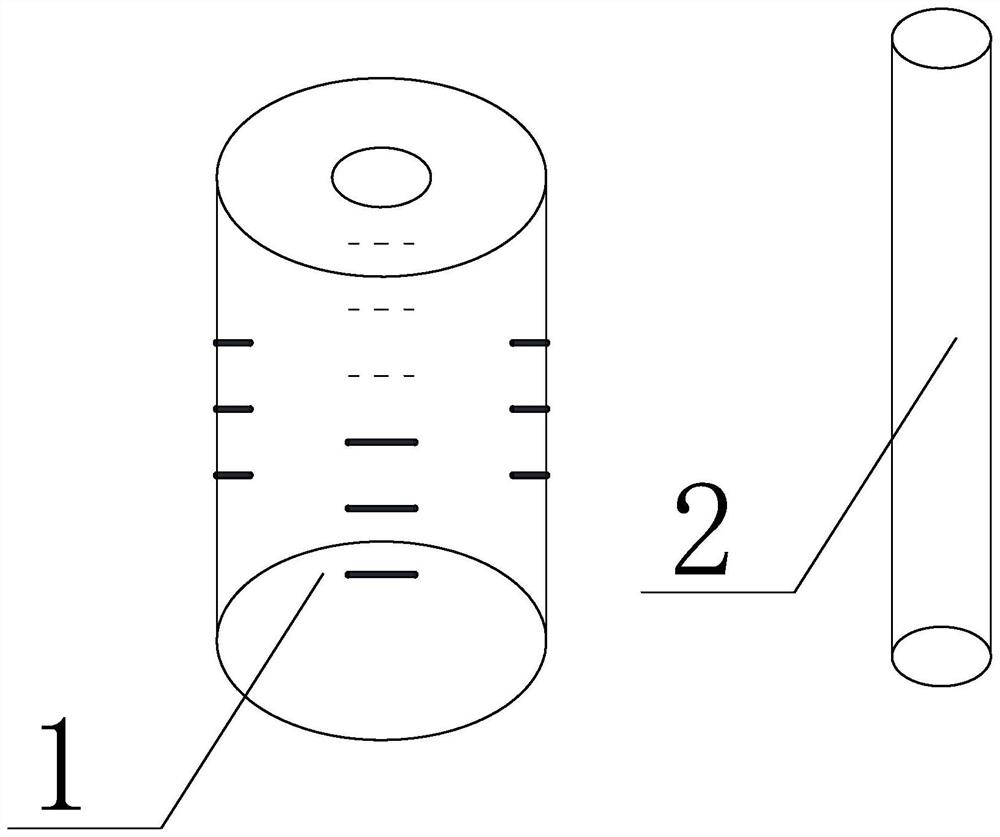

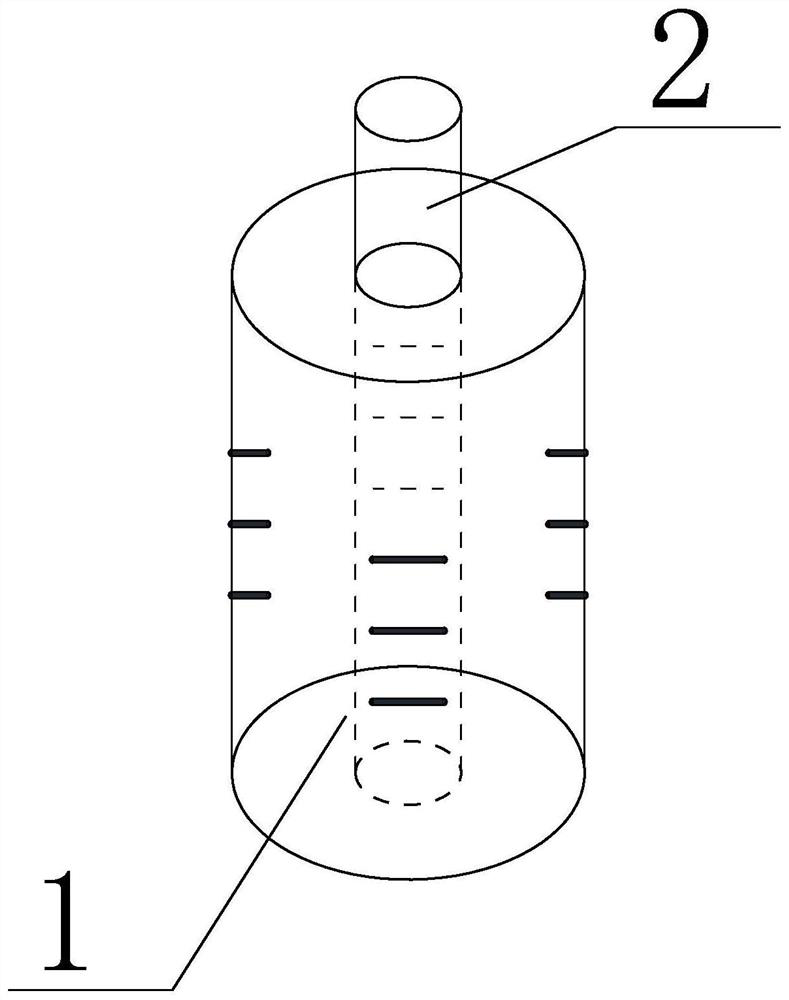

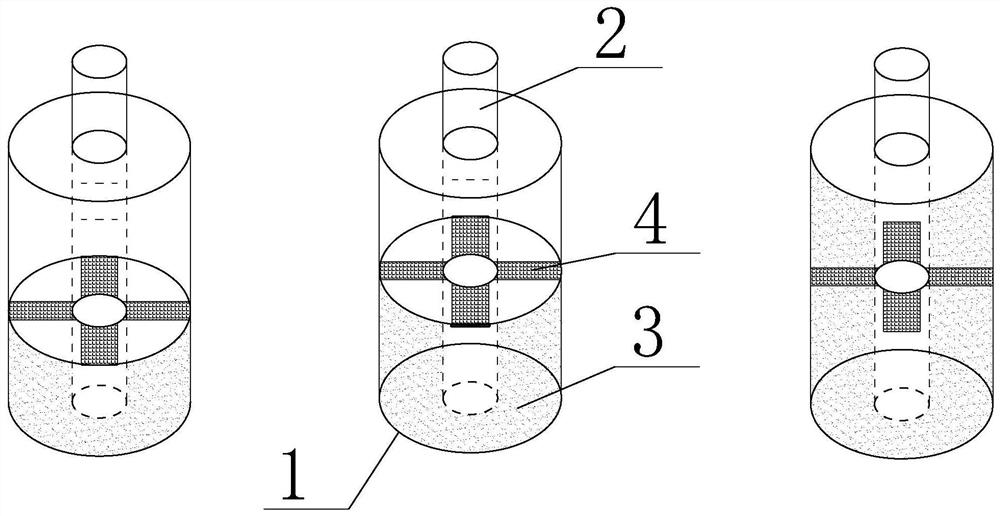

[0058] Such as figure 1 As shown, a thick-walled cylindrical shaft surrounding rock sample is made by using a polyethylene plastic bucket 1 and a PVC pipe 2, including the following steps:

[0059] (A-1) If figure 2 As shown, the polyethylene plastic barrel 1 is set outside the PVC pipe 2, and the polyethylene plastic barrel 1 and the PVC pipe 2 are coaxial; the polyethylene plastic barrel has a wall thickness of 6-8 mm, an inner diameter of Φ200-240 mm, and a height of 280-320 mm. The wall thickness of the PVC pipe is 2.0mm, the outer diameter is Φ30-50mm, and the length is 300-350mm. In order to facilitate the installation of pre-embedded paraffin sheets and monitoring sensors, grooves are made on the outer wall of the polyethylene plastic barrel 1 w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com