Automobile shock absorber

A technology of automobile shock absorption and inner cylinder, which is applied in the direction of shock absorber, spring/shock absorber, shock absorber, etc., can solve the problem that the damping effect is limited, the compression damping force cannot be formed, and the vehicle's handling, comfort and performance are affected. Safety and reliability and other issues, to achieve the effect of improving shock absorption performance, improving impact phenomenon, and improving driving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

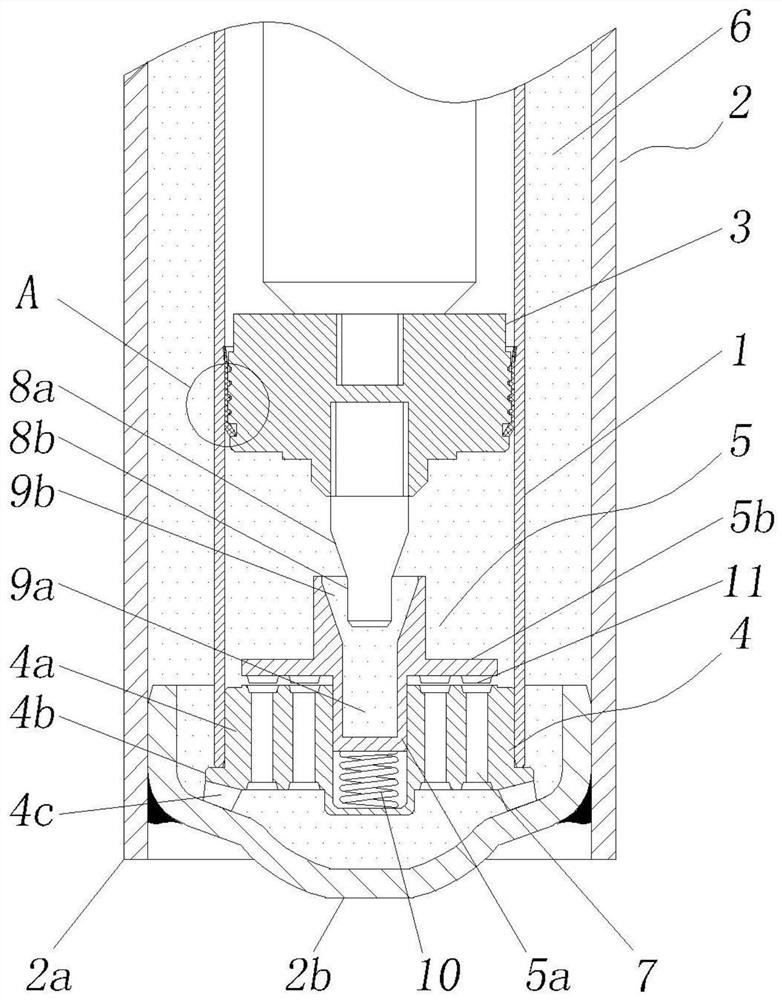

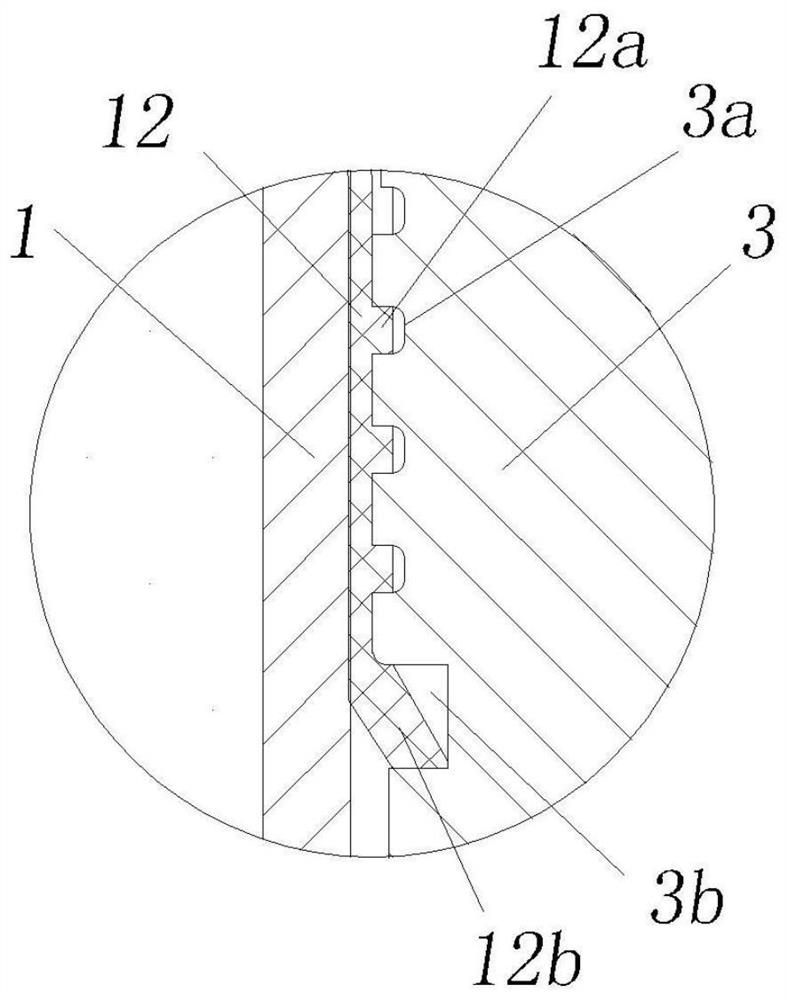

[0020] figure 1 It is a schematic diagram of the overall structure of the shock absorber; figure 2 Schematic diagram of the enlarged structure of point A of the shock absorber;

[0021] In this embodiment, an automobile shock absorption device is provided, including an outer cylinder 2 with an open top, an inner cylinder 1 sleeved inside the outer cylinder and open at both ends, a piston 3 slidingly sealed in the inner cylinder, and sealed in the inner cylinder The flow passage 4 and the valve cover 5 at the bottom have an annular liquid cavity 6 between the inner cylinder and the outer cylinder, and a damping hole 7 connecting the inner cylinder cavity and the annular liquid cavity is opened on the flow passage assembly, so The valve cover can be slid up and down on the overflow member to close or open the damping hole, and the bottom of the piston is connected with an anti-bottom member 8. A non-contact downward force causes the valve cover to close the orifice preventing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com