Electroplating bath for precious metal processing

A technology of electroplating tanks and precious metals, applied in the direction of plating tanks, electrolytic processes, electrolytic components, etc., can solve problems such as human hazards, difficult removal of products, and impact on production efficiency, so as to reduce labor intensity, solve products that are difficult to take and place, and solve The effect of gas spill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

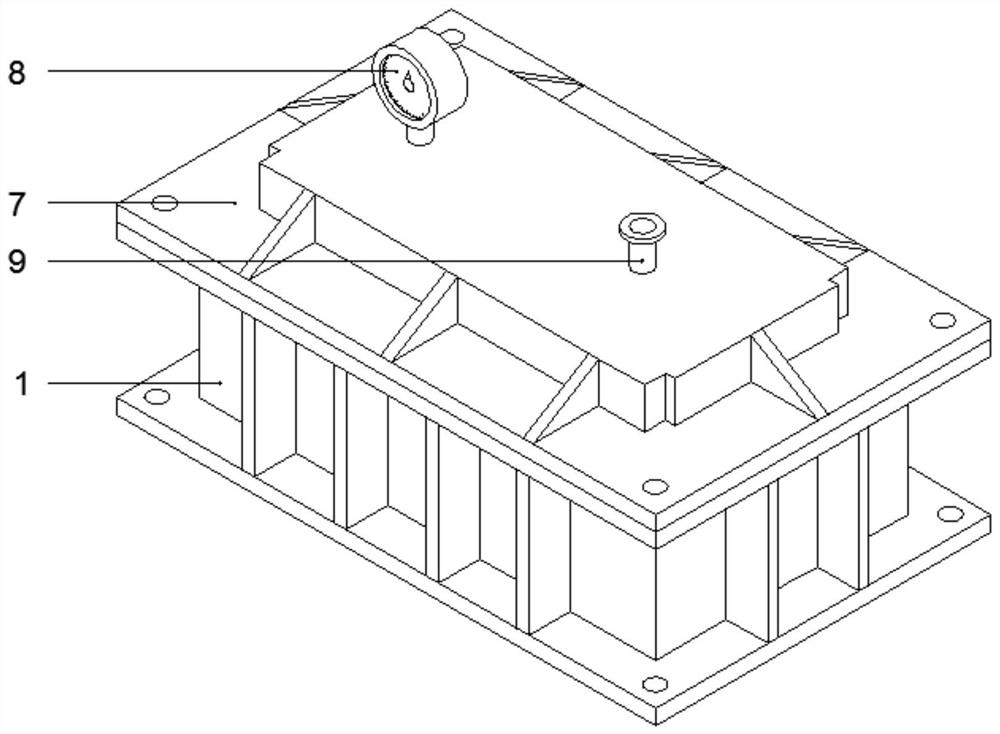

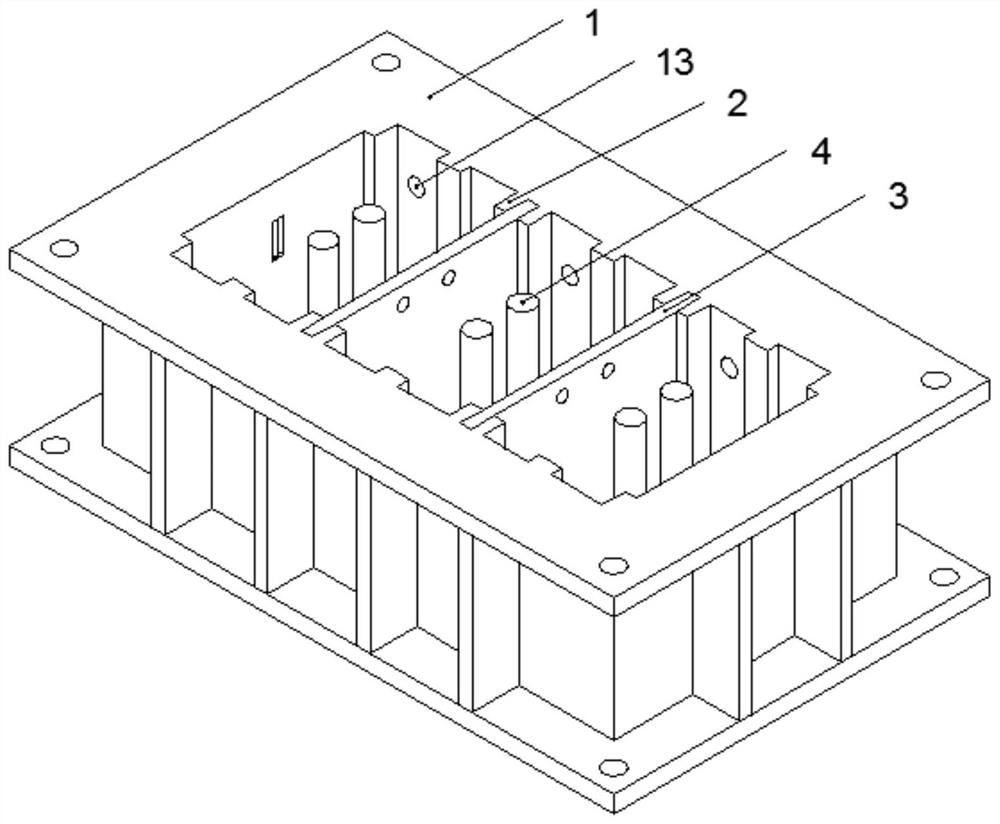

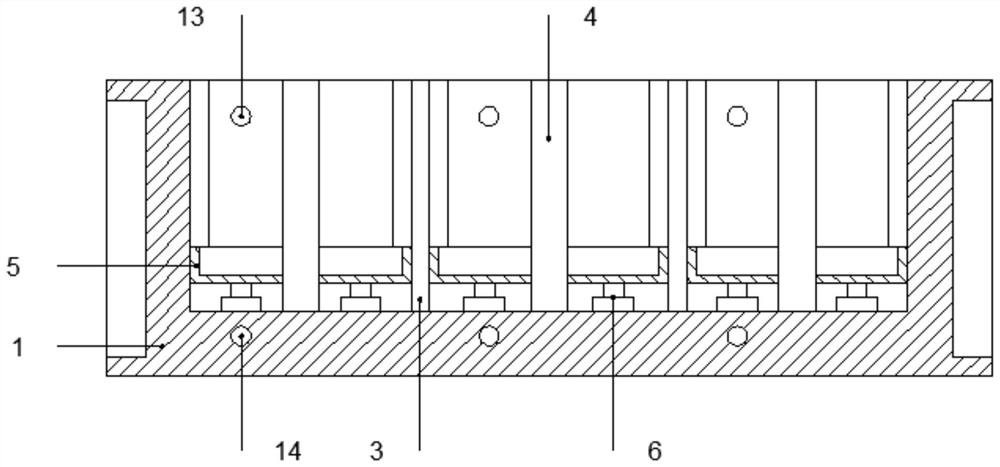

[0021]Example: such asFigure 1-4As shown, an electroplating tank for processing precious metals of the present invention includes a main tank body 1. The inner side wall of the main tank body 1 is provided with several sets of fixing frames 2, and the fixing frames 2 are equidistantly distributed on the longer side wall of the main tank body 1. On the upper side, a partition 3 is installed in each group of the fixing frame 2. The partition 3 divides the main tank body 1 into a number of independent sub-tank bodies of equal size, and a pair of electrolytic electrodes 4 are fixedly installed on the bottom side of the sub-tank body. The electrolysis electrodes 4 are respectively the cathode and the anode. The electrolysis electrodes 4 are equipped with a recovery frame 5, and the bottom of the recovery frame 5 is fixedly installed with a pair of telescopic rods 6, and the other end of the telescopic rod 6 is fixedly mounted on the inner bottom of the main tank body 1. On the other hand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com