Sorting and discharging apparatus and sorting and discharging method of testing and sorting machine for MOS transistor

A technology for sorting and unloading devices and testing sorting machines, which is applied to devices using optical methods, sorting, etc., can solve problems such as low shipping efficiency, and achieve rapid material collection, rapid material cutting, and difficult to fly out. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following is attached Figure 1-7 The application is described in further detail.

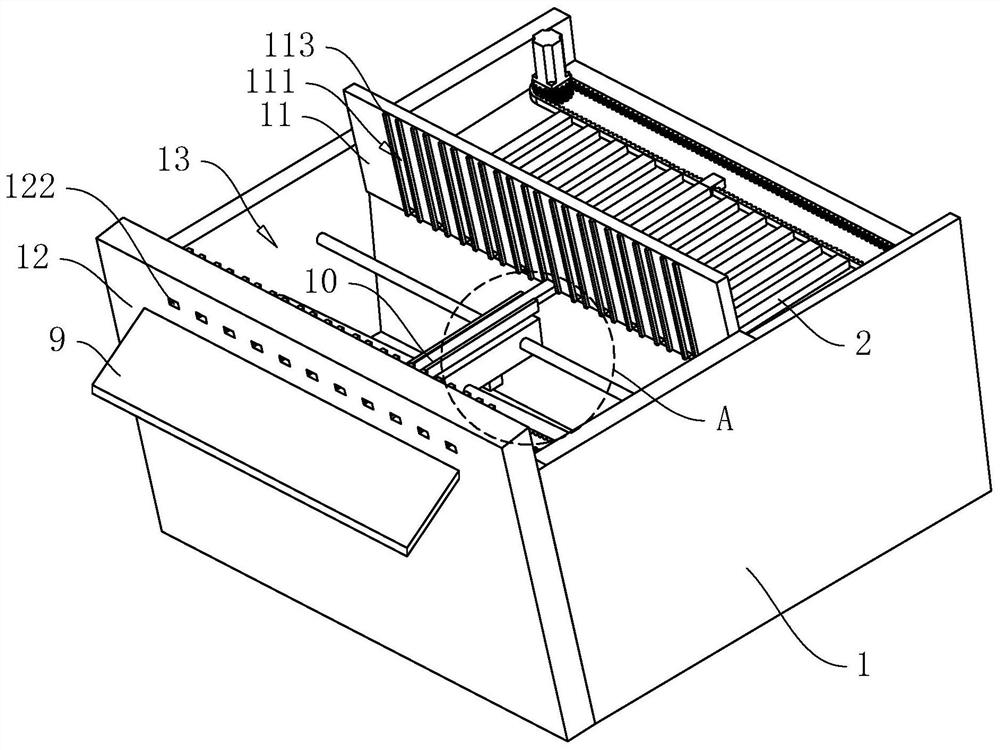

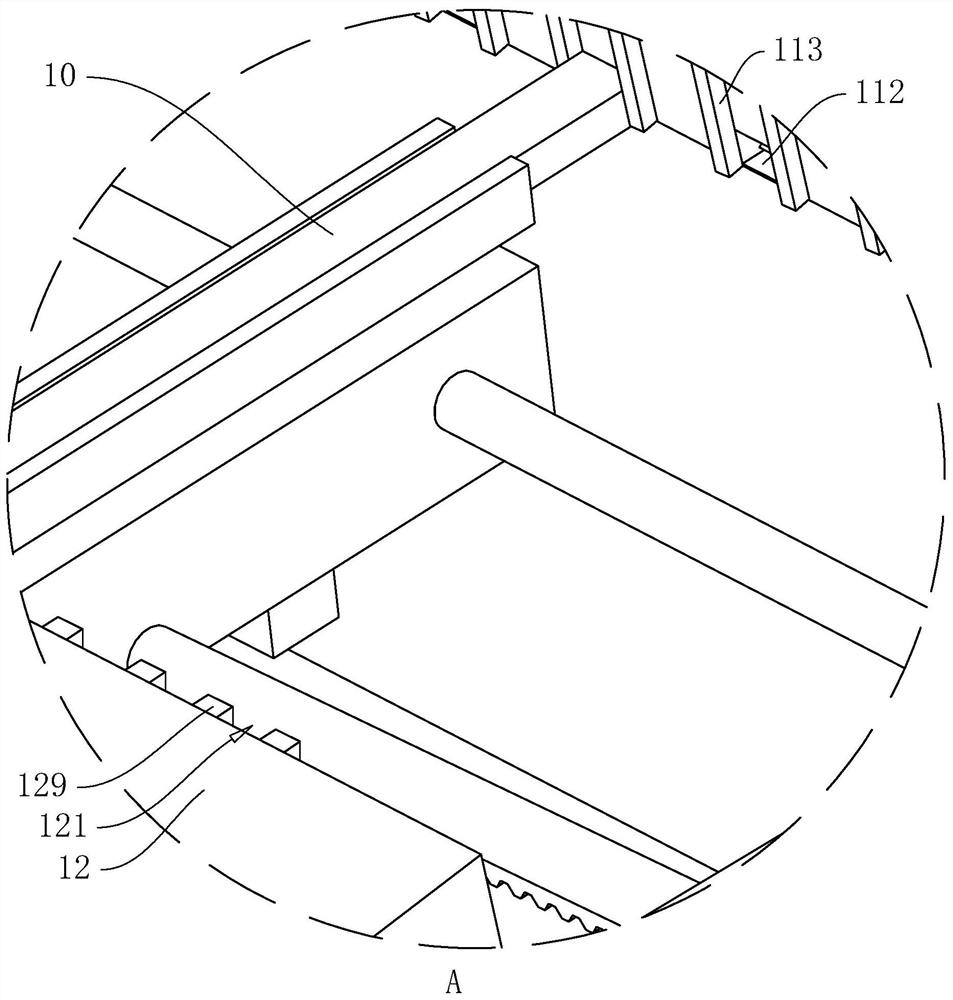

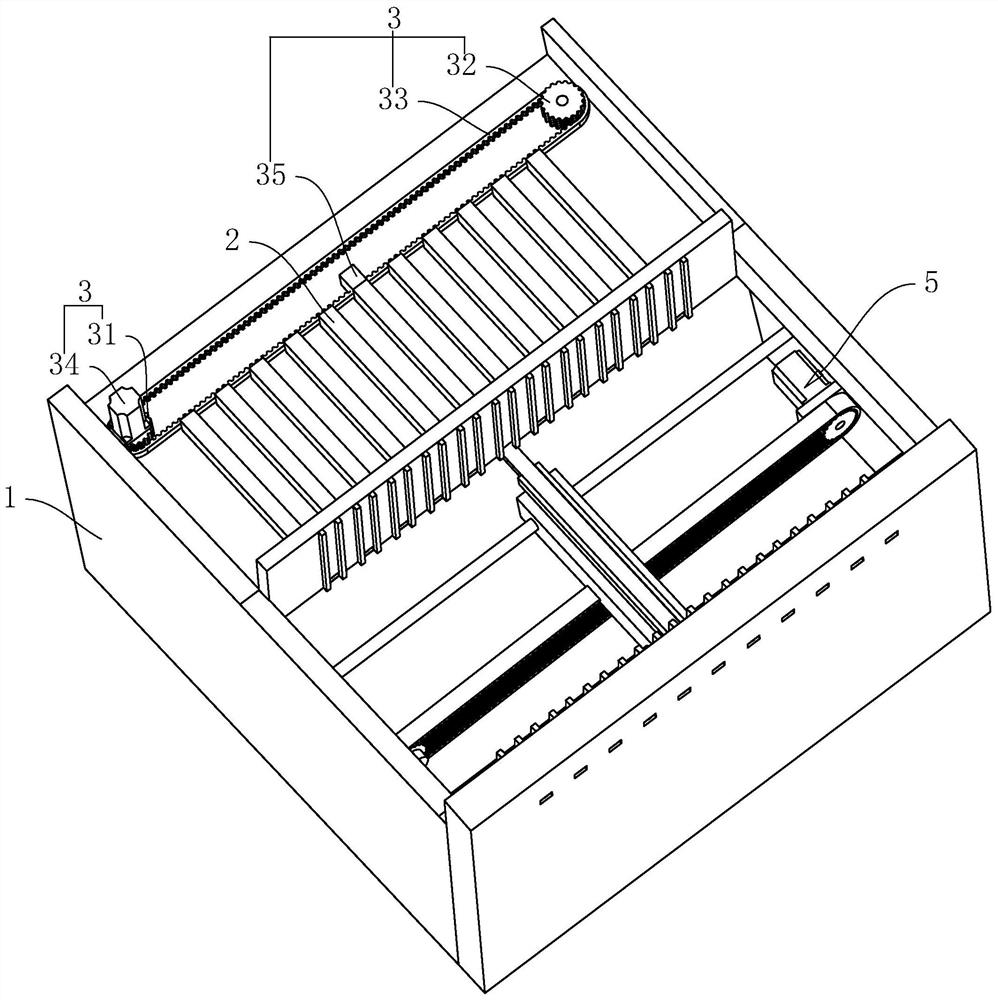

[0046] The embodiment of the present application discloses a sorting and unloading device of a MOS tube testing and sorting machine. refer to figure 1 and figure 2 , the sorting and blanking comprises a sorting rack 1, the sorting rack 1 is fixedly connected with a first material plate 11 and a second material plate 12, the position of the first material plate 11 is higher than the second material plate 12, and the first material plate 11 and the second material plate 12 form a storage space 13 for storing the receiving box 10 . The first material plate 11 is fixedly connected with the first limiting column 113 on the side facing the second material plate 12, and the first positioning groove 111 is formed between the first limiting columns 113, and the first positioning groove 111 is along the first material plate. 11 are evenly distributed along the length direction. The secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com