Preparation method of strong-flavor passion fruit juice

A production method, the technology of passion fruit, which is applied in the direction of food ingredients as odor improver, food ingredients containing natural extracts, food science, etc., can solve the problems of peculiar smell, reduction of fruit commodity value, and easy shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step (1) Juice sample preparation

[0027] According to the technological process: passion fruit→fruit picking, fruit washing→segmentation→pulp pulp→filter the seed pulp through gauze to obtain fresh raw juice→deploy juice→colloid mill→homogenize→sterilize→fill→invert bottle→cool→juice finished product.

[0028] Step (2) Titian

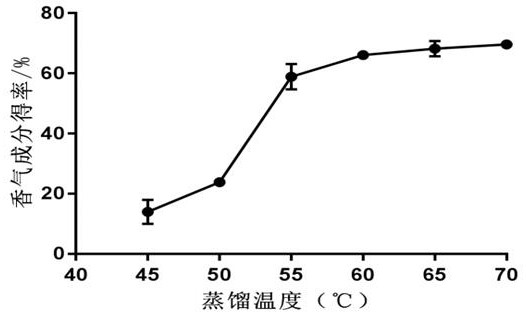

[0029] Extraction process of aroma components of passion fruit juice: Weigh 250 g of fresh passion fruit juice and put it in a rotary evaporator distillation concentration bottle for heating and distillation. The aroma components were extracted under the temperature conditions of 55°C, 60°C, and 65°C.

[0030] Step (3) Fill the incense

[0031] The mass ratio of the blended fruit juice prepared in step (1) to the aroma component is 12:1, after the sterilization step in step (1), the aroma component is filled into the fruit juice, the cap is sealed, and the bottle is inverted.

[0032] The passion fruit is 'Fujian Passion Fruit No. 1'.

[0...

Embodiment 2

[0036] Step (1) Juice sample preparation

[0037] According to the technological process: passion fruit→fruit picking, fruit washing→segmentation→pulp pulp→filter the seed pulp through gauze to obtain fresh raw juice→deploy juice→colloid mill→homogenize→sterilize→fill→invert bottle→cool→juice finished product.

[0038] Step (2) Titian

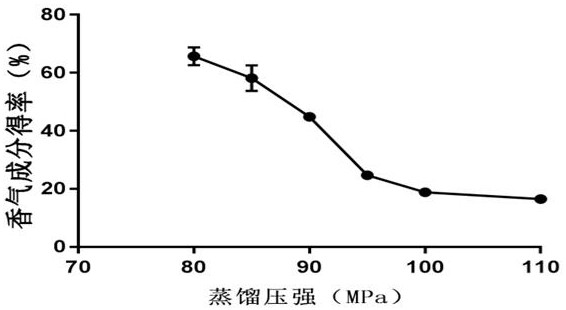

[0039] Extraction process of aroma components of passion fruit juice: Weigh 250 g of fresh passion fruit juice and place it in a rotary evaporator distillation and concentration bottle for heating and distillation. The aroma components were extracted under the pressure conditions of 80Mpa, 85Mpa and 90Mpa respectively.

[0040] Step (3) Fill the incense

[0041] The mass ratio of the blended fruit juice prepared in step (1) to the aroma component is 12:1, after the sterilization step in step (1), the aroma component is filled into the fruit juice, the cap is sealed, and the bottle is inverted.

[0042] The passion fruit is 'Fujian Passion F...

Embodiment 3

[0046] Step (1) Juice sample preparation

[0047] According to the technological process: passion fruit→fruit picking, fruit washing→segmentation→pulp pulp→filter the seed pulp through gauze to obtain fresh raw juice→deploy juice→colloid mill→homogenize→sterilize→fill→invert bottle→cool→juice finished product.

[0048] Step (2) Titian

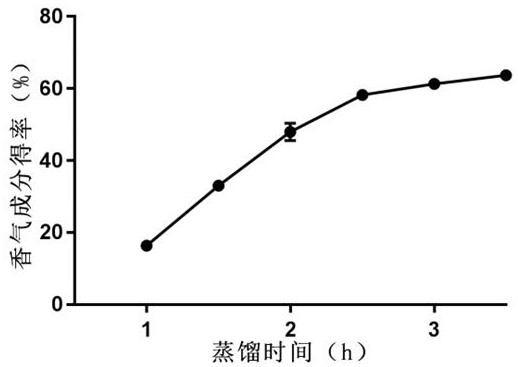

[0049] Extraction process of aroma components of passion fruit juice: Weigh 250 g of fresh passion fruit juice, put it in a rotary evaporator distillation and concentration bottle, heat and distill, under the condition of constant condensation temperature 8±2°C, with distillation temperature 60°C and distillation pressure 85 Mpa , the aroma components were extracted under the condition of 2.0 h, 2.5 h, 3.0 h distillation time respectively.

[0050] Step (3) Fill the incense

[0051] The mass ratio of the blended fruit juice prepared in step (1) to the aroma component is 12:1, after the sterilization step in step (1), the aroma component is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com